Integrated multifunctional pulling head water channel structure

A pull-out and multi-functional technology, applied in the field of faucets, can solve the problems of reducing production and assembly costs, difficulty in realizing flexible switching between large and small water flows, and high assembly costs, so as to reduce production and assembly costs, reduce product malfunctions, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

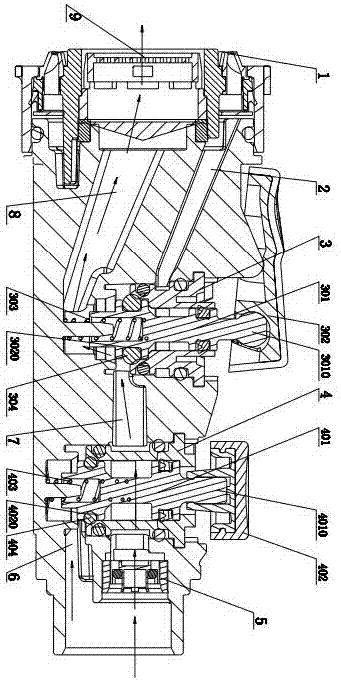

[0028] The invention discloses an integrated multifunctional drawing head waterway structure. refer to figure 1 , figure 1 It is a state schematic diagram of a state of the integrated multi-functional drawing head water channel structure according to the present invention, that is, the state of the first water outlet hole 9 with a small flow rate of water: the integrated multi-functional drawing head water channel structure includes a valve seat 10, The valve seat 10 is integrally formed, the valve seat 10 is provided with a main channel 7, and the main channel 7 is provided with a first channel 8, a second channel 2 and a flow increasing channel 6; The water channel 8 and the second water channel 2 are arranged at the water outlet of the main water channel 7, and a function switching mechanism 3 is arranged at the junction thereof, and the flow-increasing channel 6 is arranged near the water inlet of the main water channel 7, and the junction thereof A flow control mechanis...

Embodiment 2

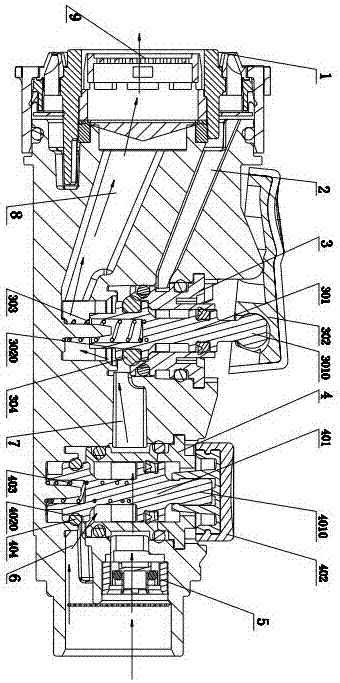

[0037] This embodiment is a state schematic diagram of another functional state of the integrated water channel structure of the pulling head according to the present invention, that is, the state of large flow of water from the first water outlet hole 9 . refer to figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the flow control button 402 is in a pressed state in this state. At this time, the second valve rod 401 moves downward under the action of external force, compressing the second The second spring 403 at the bottom of the valve stem 401, at the same time, the second plug portion 4020 on the second valve stem 401 and the second sealing ring 404 on the second plug portion 4020 move downward, and then, the flow-increasing channel The connection between 6 and the main waterway 7 is changed from a blocking body to an on state. Obviously, in this state, the function switch button 302 is in the front pressed state consistent with the state i...

Embodiment 3

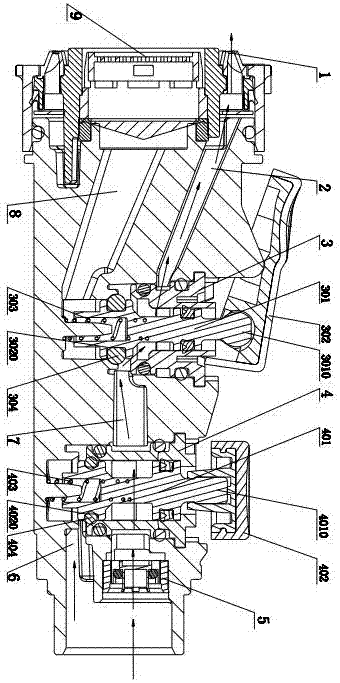

[0040] This embodiment is a state schematic diagram of another functional state of the integrated water channel structure of the pulling head according to the present invention, that is, the water outlet state of the second water outlet hole 1 with a small flow rate. refer to image 3 As shown, the difference between this embodiment and Embodiment 1 is that the front part of the function switching button 302 is lifted in this state, and the first valve rod 301 is lifted on the front part of the function switching button 302. Under the action of external force, the first spring 303 is compressed to move downward, the first plug portion 3020 and the first sealing ring 304 on the first valve rod 301 move downward, and the first water channel 8 and the Under the action of the first plug portion 3020 and the first sealing ring 304, the main water channel 7 is changed from the connected state to the blocked sealing state, and the second water channel 2 and the main water channel 7 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com