Automobile LED headlamp

A technology of headlights and LED chips, which is applied in the direction of headlights, lighting devices, vehicle parts, etc., can solve the problems of not meeting user requirements, shortening life, and large fastening force, so as to avoid current mutual influence and protect Printed circuit, the effect of fast heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

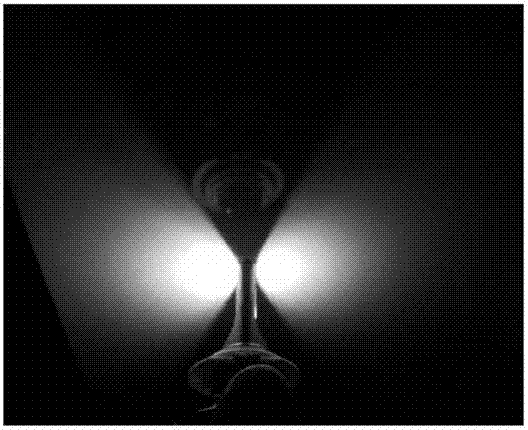

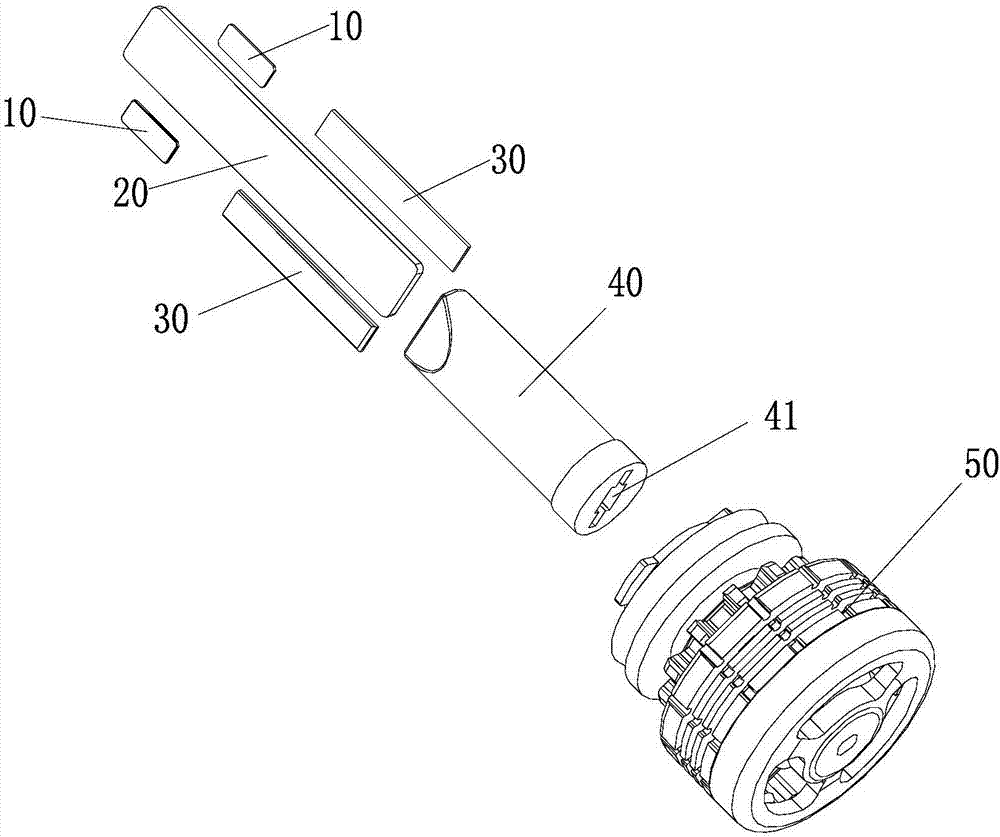

[0024] Such as figure 1 , 2 As shown in , 3, a kind of automobile LED headlamp of the present embodiment includes a substrate 20, an LED chip 10 arranged on the substrate 20, and a fixed heat conduction tube 40, and the substrate 20 is a metal plate that has been electrothermally separated. Circuits are printed on both sides of the substrate 20, the circuit is connected to the LED chip 10, the thickness of the substrate 20 is 0.8-2 mm, and a heat-conducting copper plate 30 is arranged on each side of the substrate 20, and the heat-conducting copper plate 30 and the substrate 20 Seamless connection, the fixed heat conduction cylinder 40 is provided with a fixation hole 41 , and the heat conduction copper plate 30 and the base plate 20 are plugged into the fixation hole 41 .

[0025] In this embodiment, the substrate 20 is a metal plate subjected to electrothermal separation, which can isolate current without affecting the thermal conductivity. Circuits are printed on both sid...

Embodiment 2

[0029] Such as figure 1 , 2 , 3, in this embodiment, the heat conduction copper plate 30 is seamlessly connected with the inner wall of the fixing hole 41 . There are 2-8 LED chips 10 , which are fixedly arranged on the left and right sides of the substrate 20 . The thickness of the heat conducting copper plate 30 is 0.4-1.5 mm. A radiator 50 is also included, and the radiator 50 is arranged on the fixed heat conducting tube 40 . The length and width of the substrate 20 are greater than that of the heat-conducting copper plate 30, the substrate 20 extends out of the fixing hole 41, and the heat-conducting copper plate 30 does not extend out of the fixing hole 41. The substrate 20 and the fixed heat conducting cylinder 40 are made of copper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com