Safety sealed detonation device and safety detonation method

A technology of detonating device and sealing device, which is applied in blasting, earthwork drilling, mining fluid, etc. It can solve the problems that the overall sealing cannot be realized, and achieve the effect of ensuring stable detonation performance, protecting personal safety, and protecting absolute safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1, safe detonation method, the steps are as follows

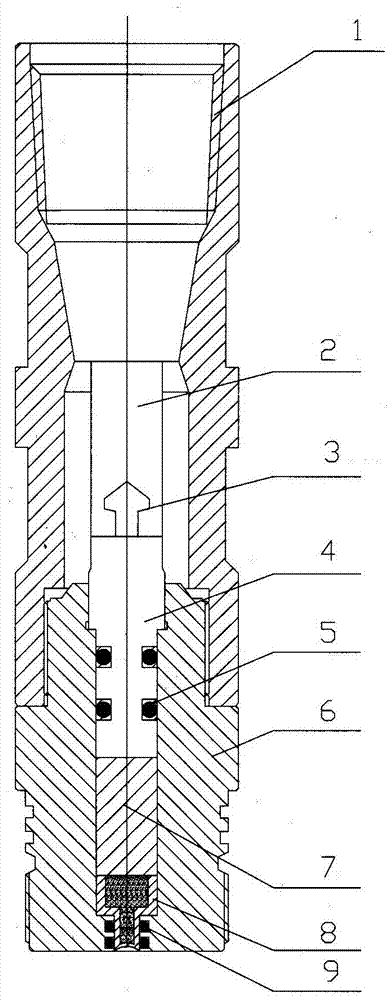

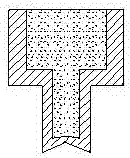

[0037] A. Assembly: First, use the existing special tools to install the reverse sealing device 9 and the explosive transmission device 8 with energy-gathering holes into the bottom of the explosive joint 6, then install the miniature detonating device 7, and finally install the forward sealing device in sequence Device 5, percussion device 4, percussion device protective cap 3, have so just formed a complete safe sealing detonation device.

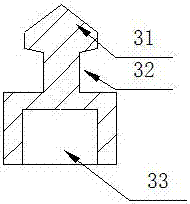

[0038] B. Remove the protective cap of the firing device: transfer the safety sealed detonating device to the detonation destination, and remove the fishing head (31) on the protective cap of the firing device with the existing special tool;

[0039] C. Detonation: After the removal is successful, hit the triggering device 4 with a special impact tool, the triggering device 4 triggers the miniature detonating device 7, the detonating device 8 receives the detonation s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com