High-speed-train dynamic-stress-test real-time data monitoring system based on GPRS data transmission

A real-time data monitoring, high-speed train technology, applied in the field of train data transmission system, can solve the problems of downloading the collected data, affecting the test quality, and changing the service performance, so as to reduce the number of test repetitions, improve the test success rate, and reduce the test cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

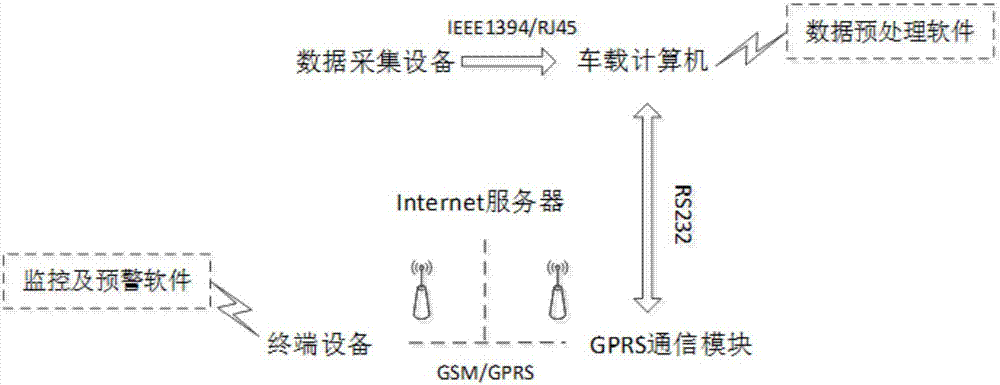

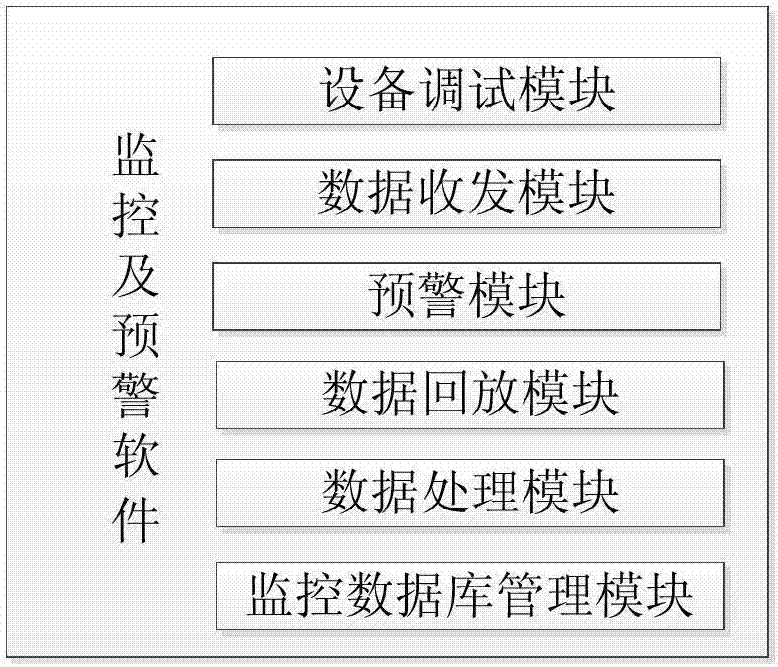

[0040]The train dynamic stress test test real-time data monitoring system of the application of the present invention is mainly made up of four parts of data acquisition equipment, vehicle-mounted computer, GPRS data transmission unit and terminal equipment, as figure 2 shown. Among them, the on-board computer is equipped with data preprocessing software to preprocess the signal to obtain the parameters to be transmitted; the terminal equipment is equipped with monitoring and early warning software, which mainly realizes data recording and abnormal early warning functions. The data transmission part adopts the commercial GPRS transmission network of China Mobile Communications Corporation. The system has the advantages of wide network information coverage, low communication cost, strong anti-interference ability and easy programming.

[0041] (1) Data acquisition equipment

[0042] According to the characteristics of dynamic stress data acquisition, commonly used data acqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com