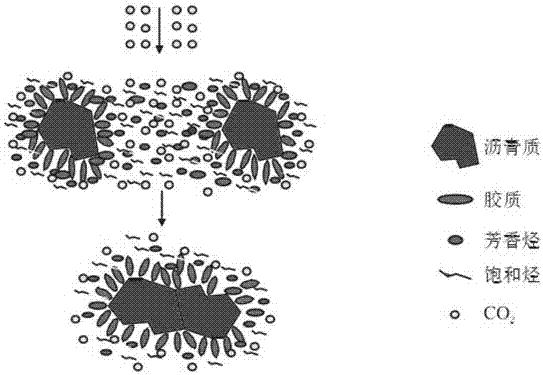

Experimental device for dynamically measuring asphaltene precipitation amount under CO2-crude oil action

A technology of dynamic measurement and experimental equipment, which is applied to the analysis of materials and instruments, can solve the problems of complex equipment, high cost, and long time consumption, and achieve the effect of convenient operation, low cost, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

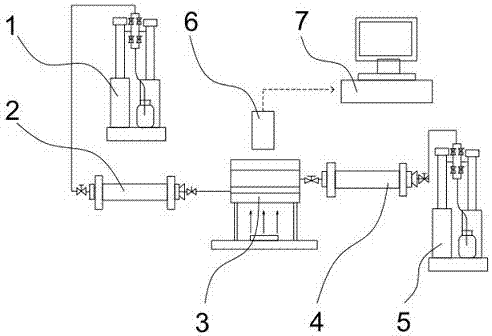

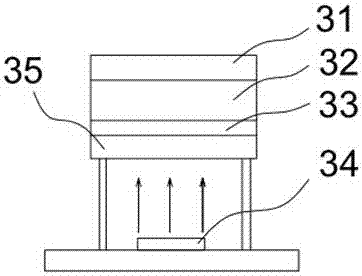

[0019] Dynamic measurement of CO 2 - An experimental device for producing asphaltene precipitation by the action of crude oil, including a reactor 3 and a microscope 6 located above the reactor 3, and the side of the reactor 3 is connected to a CO 2 The piston container 4 is connected with the crude oil piston container 2 on the other side; the microscope 6 is connected with the computer 7 . Reactor 3 can be seen as a high-temperature and high-pressure reactor as a cylinder, and the internal cavity of reactor 3 is also a cylinder. The operating temperature range is 0~100°C, and the maximum pressure is 25Mpa. Reactor 3 includes visual window 31, CO from top to bottom 2 Layer 32 and crude oil layer 33, below are provided with frosted glass sheet 35 and cold light source 34, are used for CO 2 Saturated oil layer provides sufficient light. CO 2 The piston container 4 is connected with the second ISCO pump 5; the crude oil piston container 2 is connected with the first ISCO pum...

Embodiment 2

[0021] Dynamic measurement of CO 2 - An experimental device for producing asphaltene precipitation by the action of crude oil, including a reactor 3 and a microscope 6 located above the reactor 3, and the side of the reactor 3 is connected to a CO 2 The piston container 4 is connected with the crude oil piston container 2 on the other side; the microscope 6 is connected with the computer 7 . Reactor 3 can be seen as a high-temperature and high-pressure reactor as a cylinder, and the internal cavity of reactor 3 is also a cylinder. The operating temperature range is 0~100°C, and the maximum pressure is 25Mpa. Reactor 3 includes visual window 31, CO from top to bottom 2 Layer 32 and crude oil layer 33, below are provided with frosted glass sheet 35 and cold light source 34, are used for CO 2 Saturated oil layer provides sufficient light. CO 2 The piston container 4 is connected with the second ISCO pump 5; the crude oil piston container 2 is connected with the first ISCO pum...

Embodiment 3

[0024] Dynamic measurement of CO 2 - An experimental device for producing asphaltene precipitation by the action of crude oil, including a reactor 3 and a microscope 6 located above the reactor 3, and the side of the reactor 3 is connected to a CO 2The piston container 4 is connected with the crude oil piston container 2 on the other side; the microscope 6 is connected with the computer 7 . Reactor 3 can be seen as a high-temperature and high-pressure reactor as a cylinder as a whole, and the internal cavity of reactor 3 is also a cylinder. The operating temperature range is 0~100°C, and the maximum pressure is 25Mpa. Reactor 3 includes visual window 31, CO from top to bottom 2 Layer 32 and crude oil layer 33, below are provided with frosted glass sheet 35 and cold light source 34, are used for CO 2 Saturated oil layer provides sufficient light. CO 2 The piston container 4 is connected with the second ISCO pump 5; the crude oil piston container 2 is connected with the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com