High-power DC charging machine

A charger and high-power technology, applied in the direction of converting DC power input to DC power output, charging stations, efficient vehicle charging, etc., can solve the problems of shortened service life, expensive modules, accelerated modules, etc., to improve service life. , The effect of improving the IP protection level and improving the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

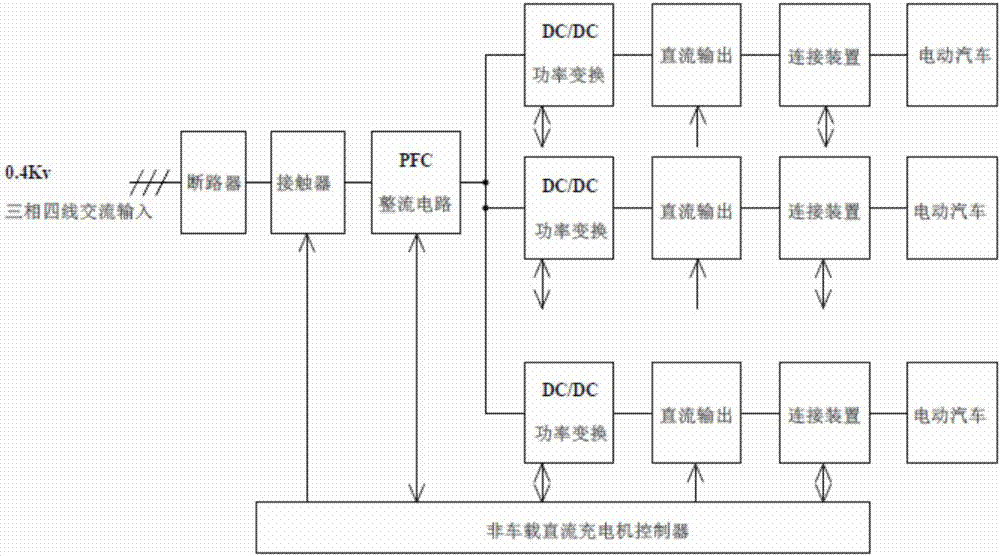

[0028] The structure diagram of the present invention is as Figure 1-5 As shown, the high-power DC charger of the present invention includes a circuit breaker, a contactor, a PFC rectifier circuit, a number of charging circuits, and an off-vehicle DC charger controller, and the three-phase four-wire AC input voltage is connected to the contactor through the circuit breaker , the output of the contactor is connected to the input terminal of the PFC rectifier circuit, the output terminal of the PFC rectifier circuit is divided into multiple channels, which are respectively connected to several charging circuits, and the output terminals of several charging circuits respectively output direct current to the electric vehicle, wherein, the contactor, the PFC rectifier circuit And each charging circuit is connected with the non-vehicle DC charger controller. independently subject to its control.

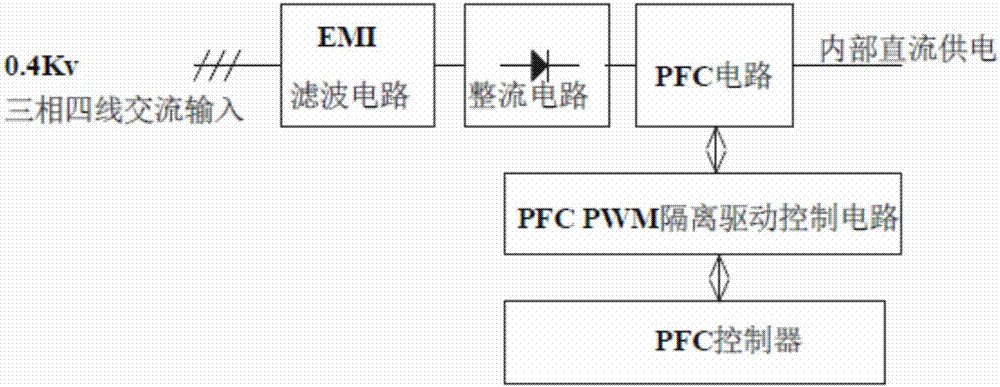

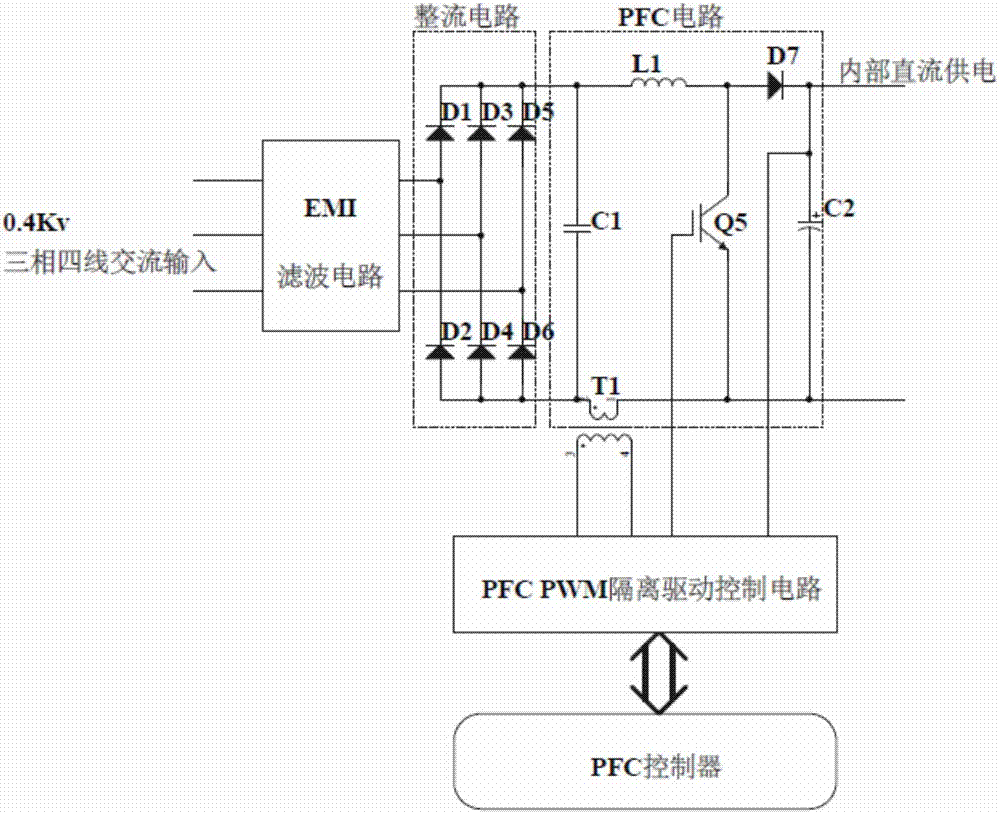

[0029]In this embodiment, the above-mentioned PFC rectifier circuit includes an EMI ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com