Carrying equipment provided with high-strength backpack bracket, and preparation technology of backpack bracket

A production process and high-strength technology, applied in the field of backpack brackets, can solve the problems of enlargement, early appearance time, and significantly reduced soldier stability, and achieve the effects of reducing bearing capacity, prolonging service life, and improving comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

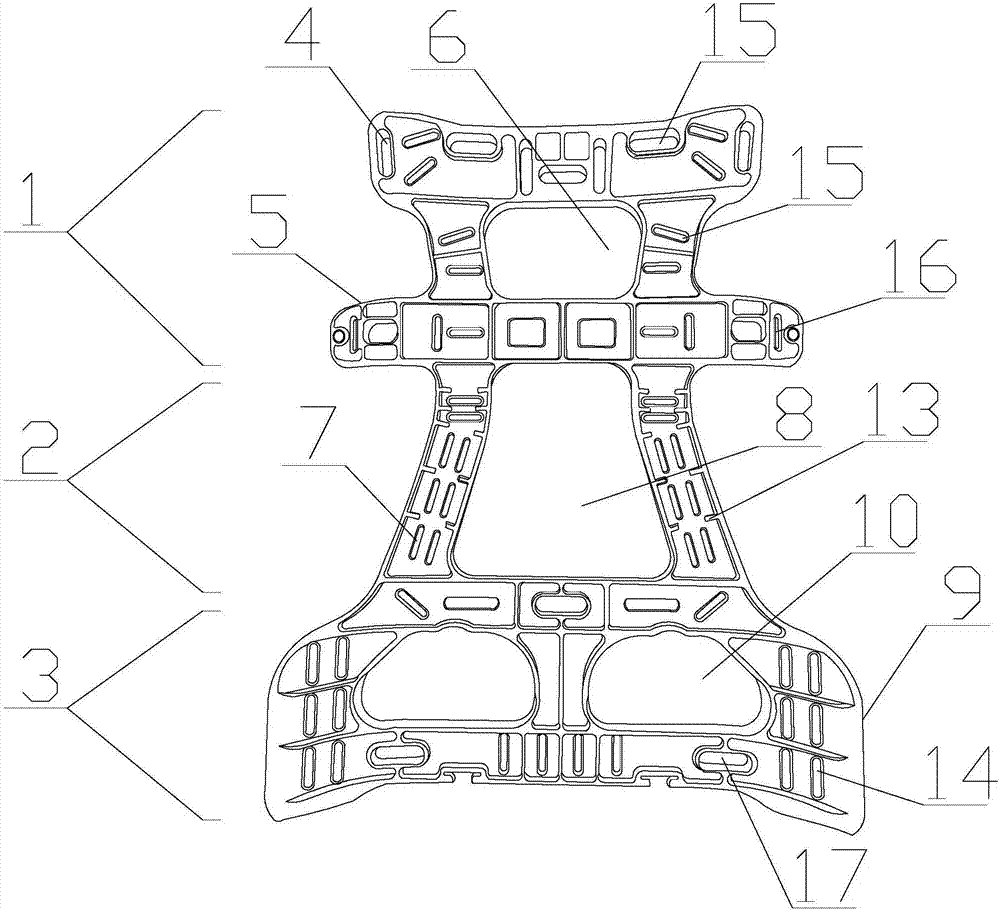

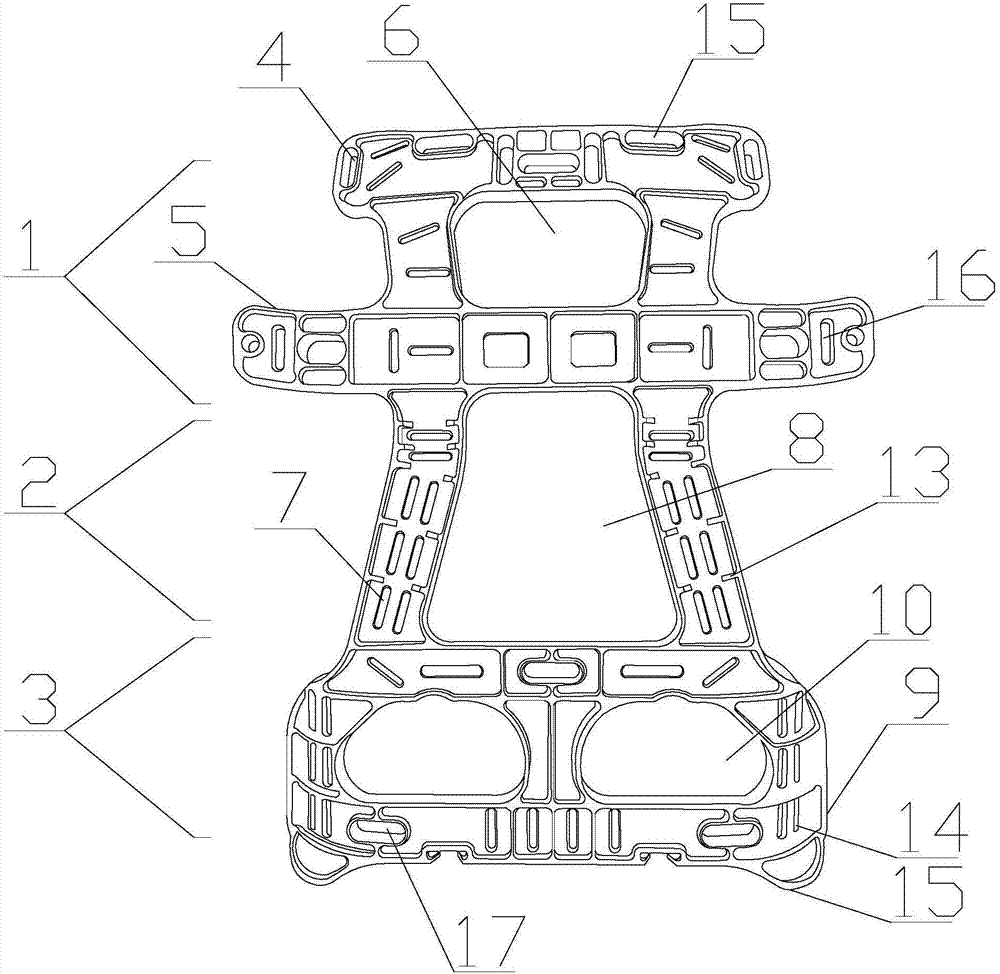

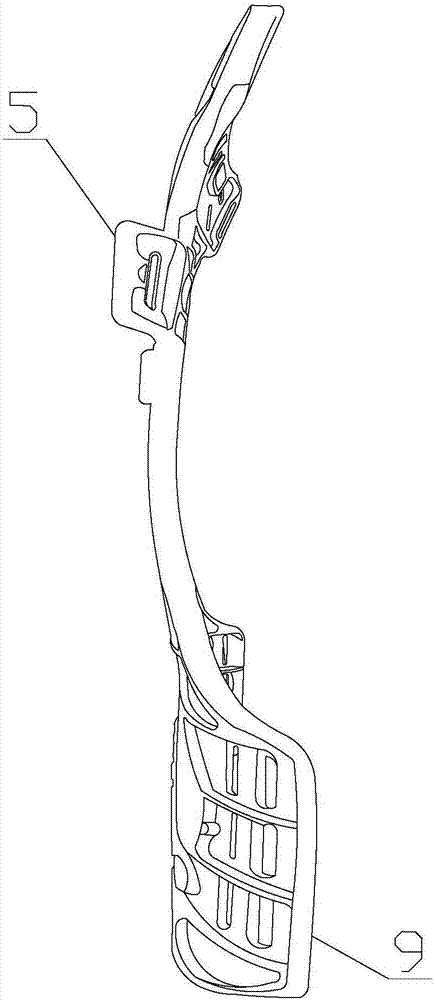

[0055] Such as Figure 1 to Figure 11 As shown, the carrying equipment with a high-strength backpack bracket of the present invention includes a backpack bracket, a shoulder strap assembly module, a waist support assembly and a backpack, the top of the backpack bracket is detachably connected to the shoulder strap assembly module, and the backpack The bottom of the bracket is detachably connected to the lumbar support assembly, and one side of the backpack bracket is detachably connected to the backpack, wherein the backpack bracket is in the shape of an arc with an arc of 20°, and the front and rear sides of the backpack bracket are Both are provided with grooves with the same depth, and the bottom of the grooves is provided with a connecting plate for fixed connection. The structure of the left and right sides of the backpack bracket is symmetrical, and the backpack bracket includes the shoulder strap assembly connecting module 1, The backpack connection module 2 and the wai...

Embodiment 2

[0076] The carrying equipment with a high-strength knapsack bracket of the present invention comprises a knapsack bracket, a shoulder strap assembly module, a waist support assembly and a knapsack, the top of the knapsack bracket is detachably connected to the shoulder strap assembly module, and the bottom of the knapsack bracket is It is detachably connected to the lumbar support assembly, and one side of the backpack support is detachably connected to the backpack, wherein the backpack support is in the shape of an arc with an arc of 35°, and the front and rear sides of the backpack support are provided with Grooves with the same depth, the bottom of the groove is provided with a connecting plate for fixed connection, the structure of the left and right sides of the backpack support is symmetrical, and the backpack support includes a shoulder strap assembly connection module 1 and a backpack connection module from top to bottom. 2 and the lumbar support assembly connection mo...

Embodiment 3

[0097] The carrying equipment with a high-strength knapsack bracket of the present invention comprises a knapsack bracket, a shoulder strap assembly module, a waist support assembly and a knapsack, the top of the knapsack bracket is detachably connected to the shoulder strap assembly module, and the bottom of the knapsack bracket is It is detachably connected to the lumbar support assembly, and one side of the backpack support is detachably connected to the backpack, wherein the backpack support is in the shape of an arc with an arc of 50°, and the front and rear sides of the backpack support are provided with Grooves with the same depth, the bottom of the groove is provided with a connecting plate for fixed connection, the structure of the left and right sides of the backpack support is symmetrical, and the backpack support includes a shoulder strap assembly connection module 1 and a backpack connection module from top to bottom. 2 and the lumbar support assembly connection mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com