Bar continuous-type automatic machining equipment

A technology for processing equipment and bar materials, which is applied in the field of continuous automatic processing equipment for bar materials, can solve the problems of manpower consumption, low degree of automation and low production efficiency, and achieve the effects of improved efficiency, high work efficiency and convenient positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

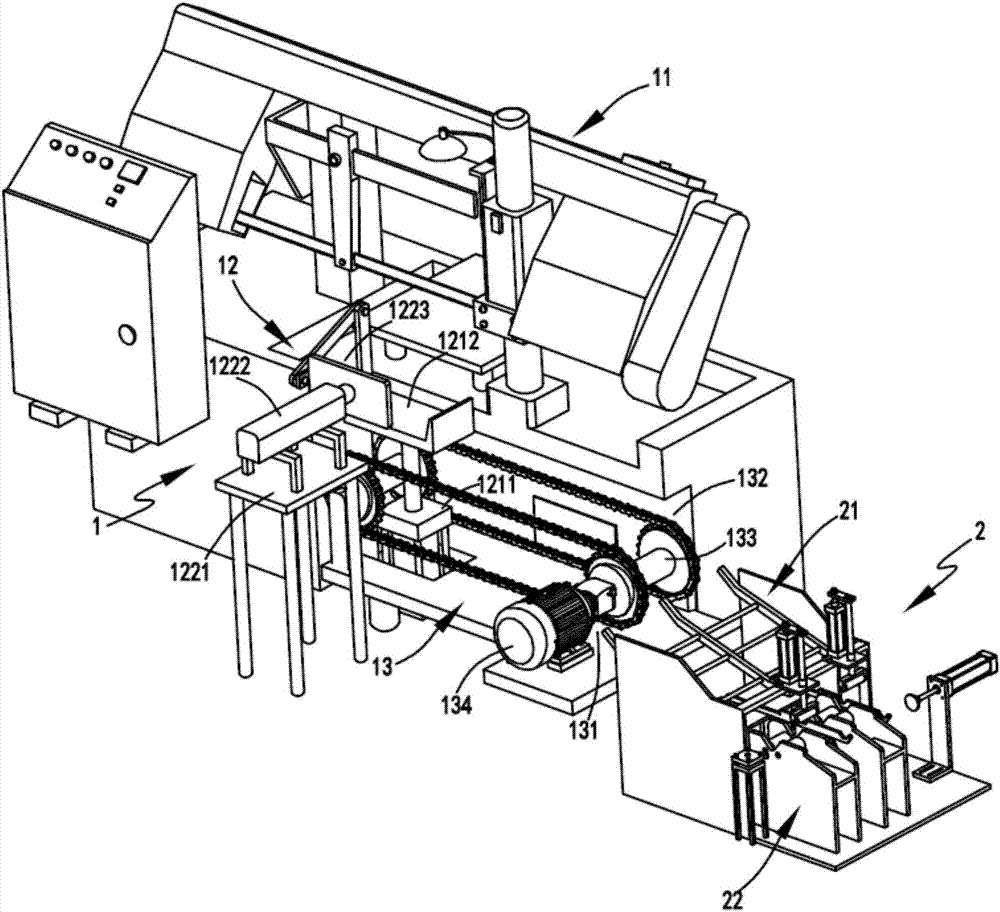

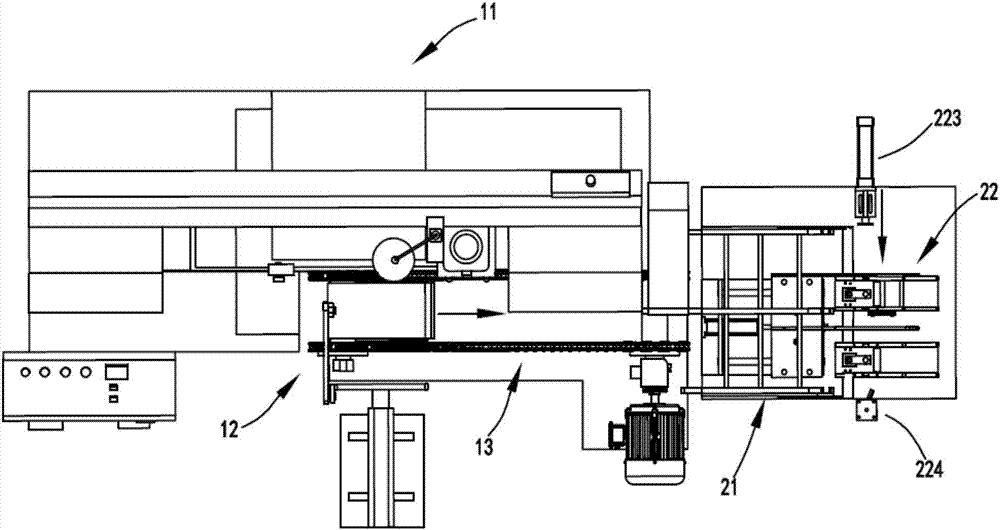

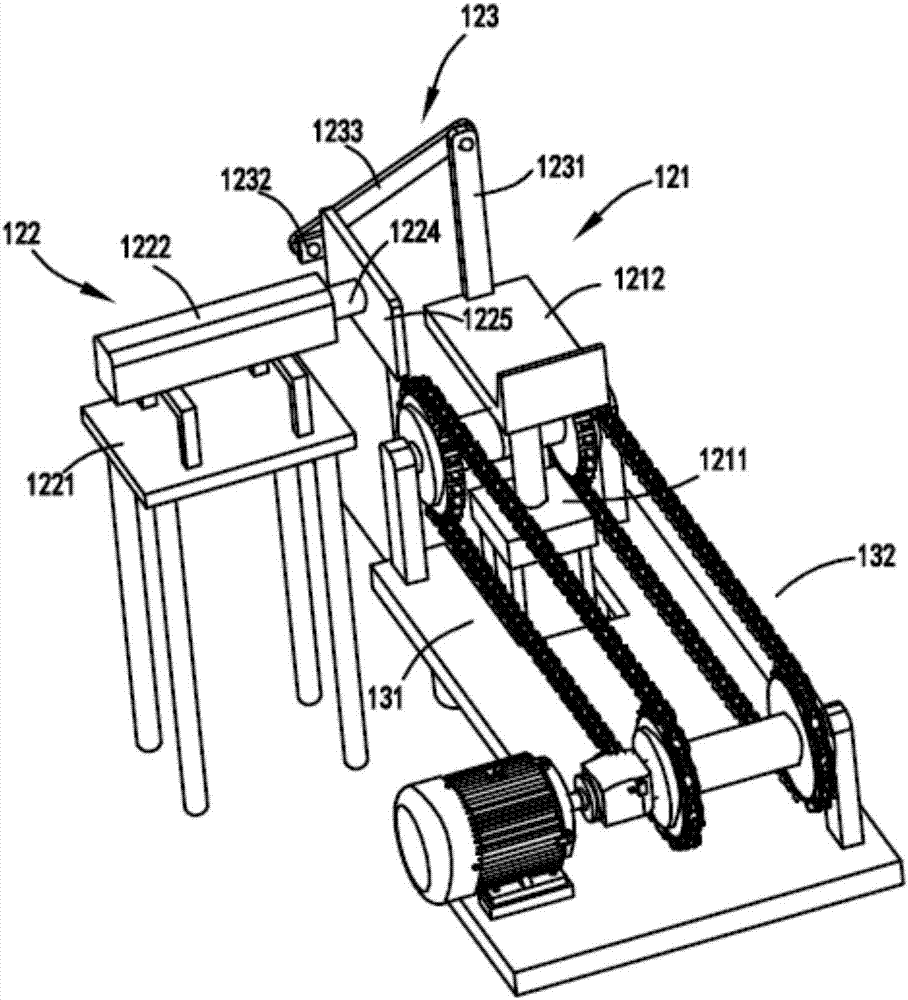

[0045] figure 1 It is a schematic diagram of the continuous automatic processing equipment for bars, figure 2 It is a top view schematic diagram of bar continuous automatic processing equipment, image 3 It is a structural schematic diagram of the positioning support mechanism and the horizontal output mechanism, Figure 4 is the structural schematic diagram of the turning part, Figure 5 It is a schematic diagram of the structure of the feeding mechanism, Image 6 It is a schematic side view of the bar when it is on the conveying device a and conveying device b, Figure 7 It is a schematic diagram of the structure of the push device, Figure 8 It is a schematic diagram of the structure when the lifting and supporting device drives the bar to move to the placement groove and the inclined surface respectively, Figure 9 Schematic diagram of the structure when the lifting and supporting device moves upward to accept the bar on the buffer rack, Figure 10 Schematic diagram...

Embodiment 2

[0067] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 with Figure 10 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that the positioning support mechanism 12 includes a lifting transfer device 121, a positioning device 122 arranged on one side of the lifting transfer device 121, and a positioning device 122 arranged between the lifting transfer device 121 and the positioning device 122. There is a transmission device 123 between them, and the transmission device 123 drives the positioning device 122 to move in the horizontal direction during the process of the lifting transfer device 121 moving in the vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com