Method for preparing immobilized fungicide by grafting dendrimer with chlorine ball and its application

A tree-shaped, catalyst-based technology, applied in the direction of fungicides, botany equipment and methods, applications, etc., can solve the problems of poor peeling and washing effects, high transportation and storage costs, toxic by-products, etc., to avoid secondary pollution, overcome Effect of residual water and improvement of bactericidal power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

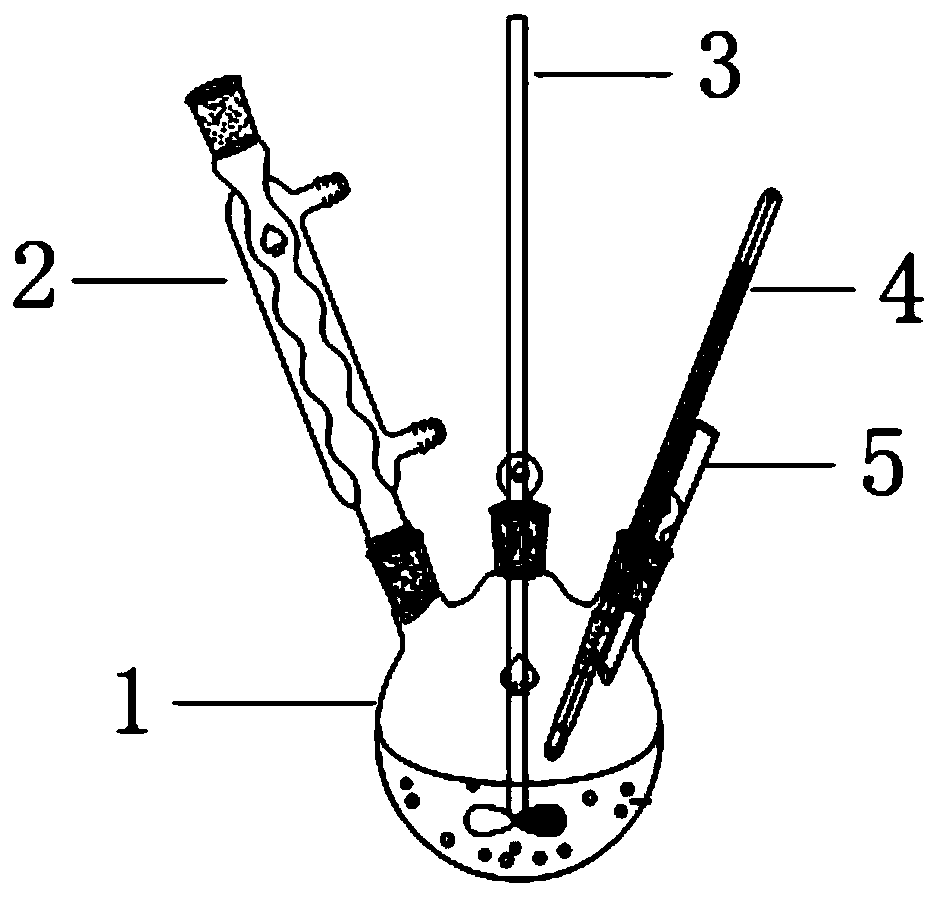

[0045] In this embodiment, the dendritic bactericidal microspheres are prepared according to the following method:

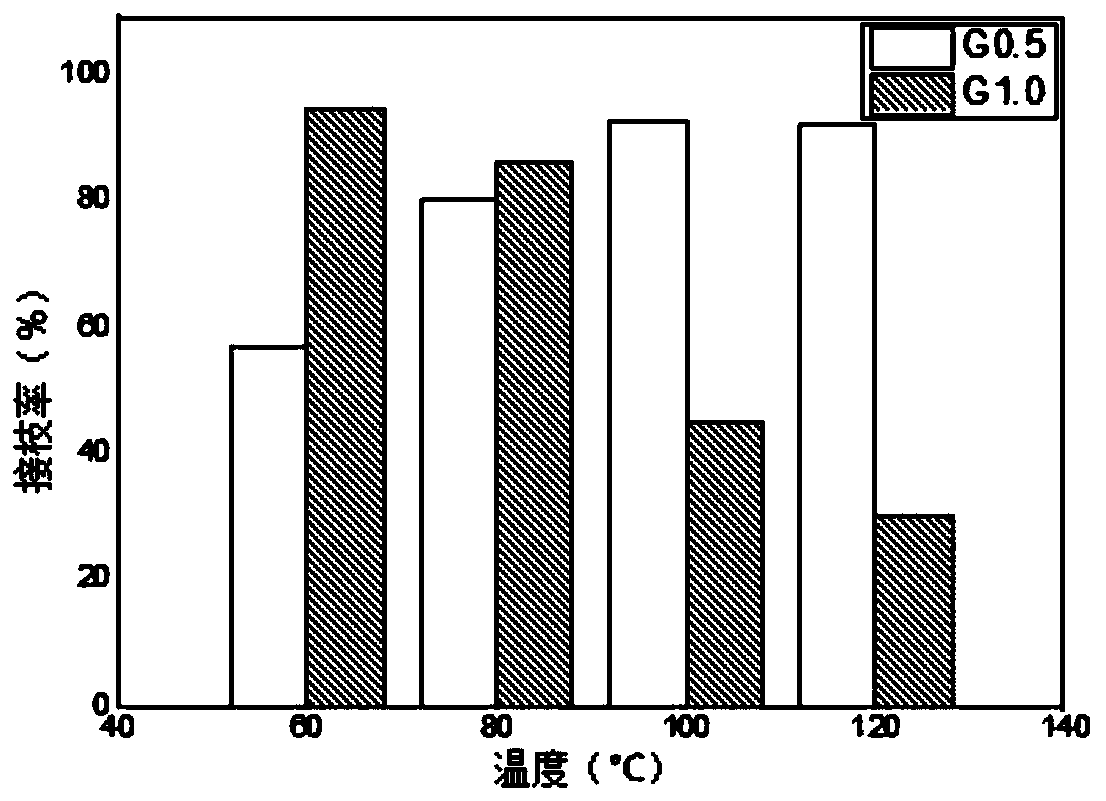

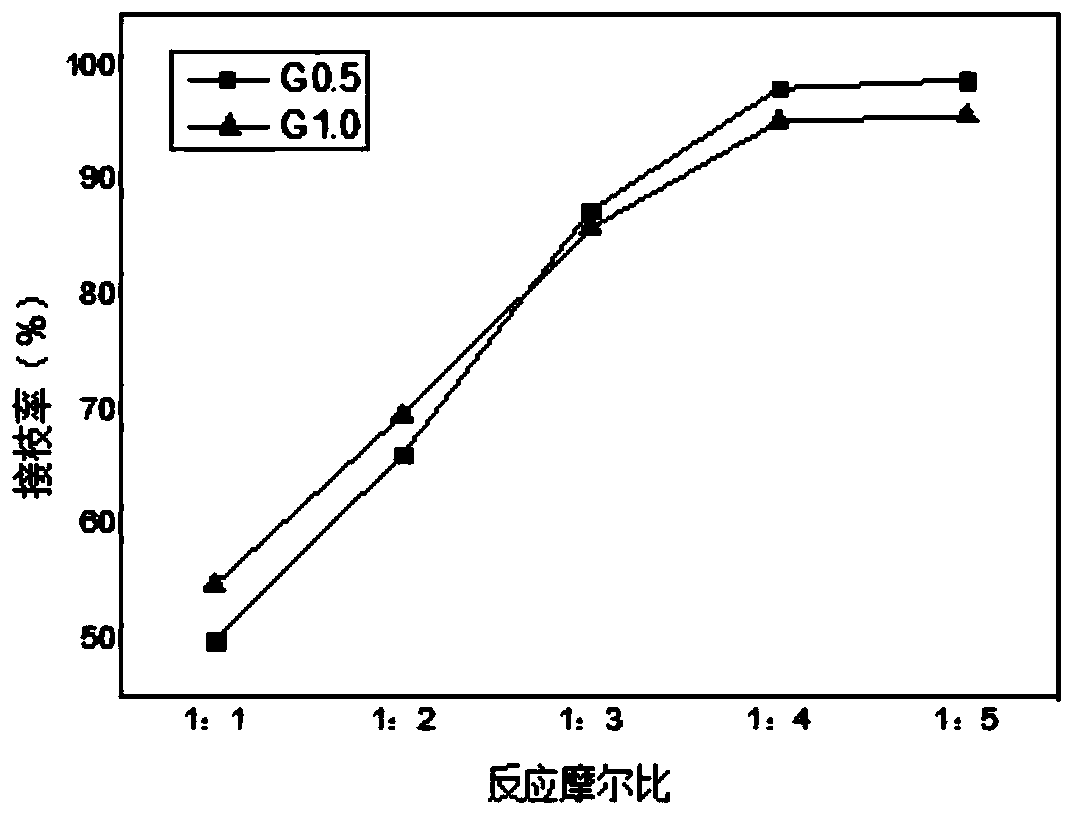

[0046] (1) Synthesis of G0.5: Weigh 15 mg of chlorine balls and place them in a 100 mL three-neck flask, add 25 mL of reaction solvent DMF, soak for 12 hours to fully swell the carrier. Add ethylenediamine and 2.25g catalyst metal sodium in the three-necked bottle then, the mol ratio of chlorine ball and ethylenediamine is 1:3, feeds N 2 Protected, stirred and reacted at 90-110°C for 10h, and filtered off the reacted G0.5. Rinse three times with the reaction solvent DMF, and soak in 1mol / L NaOH for 8 hours. Then rinse with absolute ethanol, acetone, and ether repeatedly for 3 times, and put it into a 50°C vacuum drying oven to dry for later use;

[0047] (2) Synthesis of G1.0: Weigh 15 mg of G0.5 with the largest grafting amount and place it in a 100 mL three-neck flask, add 25 mL of reaction solvent to soak for 10 h, add methyl acrylate dropwise at 0°C to 25°...

Embodiment 2

[0054] In this embodiment, the dendritic bactericidal microspheres are prepared according to the following method:

[0055] (1) Synthesis of G0.5: Weigh 15 mg of chlorine balls and place them in a 100 mL three-neck flask, add 25 mL of reaction solvent DMF, soak for 12 hours to fully swell the carrier. Add ethylenediamine and 2.25g catalyst metal sodium in the three-necked bottle then, the mol ratio of chlorine ball and ethylenediamine is 1:4, feeds N 2 Protected, stirred and reacted at 100°C for 11h, and the reacted G0.5 was filtered off. Rinse three times with the reaction solvent DMF, and soak in 1mol / L NaOH for 8 hours. Then rinse with absolute ethanol, acetone, and ether repeatedly for 3 times, and put it into a 50°C vacuum drying oven to dry for later use;

[0056] (2) Synthesis of G1.0: Weigh 15 mg of G0.5 with the largest grafting amount and place it in a 100 mL three-neck flask, add 25 mL of reaction solvent to soak for 13 hours, add methyl acrylate dropwise at 0°C t...

Embodiment 3

[0063] In this embodiment, the dendritic bactericidal microspheres are prepared according to the following method:

[0064] (1) Synthesis of G0.5: Weigh 15 mg of chlorine balls and place them in a 100 mL three-neck flask, add 25 mL of reaction solvent DMF, soak for 12 hours to fully swell the carrier. Add ethylenediamine and 2.25g catalyst metal sodium in the three-necked bottle then, the mol ratio of chlorine ball and ethylenediamine is 1:5, feeds N 2protection, stirring the reaction at 110°C for 12h, and filtering off the reacted G0.5. Rinse three times with the reaction solvent DMF, and soak in 1mol / L NaOH for 8 hours. Then rinse with absolute ethanol, acetone, and ether repeatedly for 3 times, and put it into a 50°C vacuum drying oven to dry for later use;

[0065] (2) Synthesis of G1.0: Weigh 15 mg of G0.5 with the largest grafting amount and place it in a 100 mL three-necked flask, add 25 mL of reaction solvent to soak for 15 hours, add methyl acrylate dropwise at 0°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com