Environment-friendly enzyme preparation technology and dedicated enzyme barrel thereof

An environmentally friendly enzyme and preparation process technology, which is applied in biochemical equipment and methods, bioreactor/fermenter combinations, bioreactors/fermenters for specific purposes, etc. The efflux rate is slow and the fermentation substrate cannot be fully fermented, so as to achieve the effect of prolonging the activity of aerobic strains and promoting the increase of dissolved oxygen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

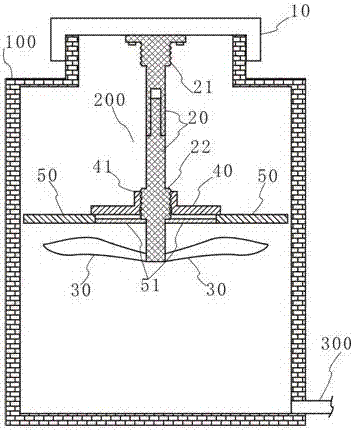

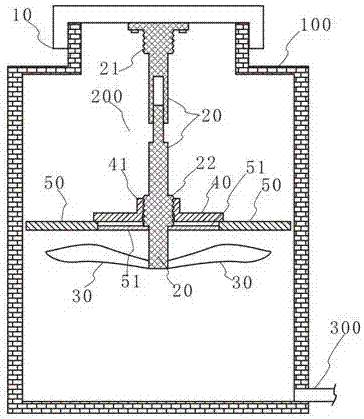

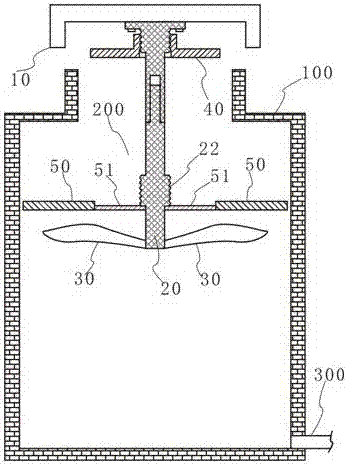

[0026] The present invention will be further described below in conjunction with accompanying drawing:

[0027] Such as Figure 1-5 As shown, the present embodiment provides a special ferment bucket prepared by an environmentally friendly enzyme, including a barrel body 100 and a bung 200, and the bung 200 includes a cover main body 10, a connecting rod 20, a stirring body 30, an inner laminate 40 and an outer Laminate 50, the connecting rod 20 is fixedly connected to the inner surface of the cover main body 10 and extends vertically downward, the stirring body 30 is detachably connected to the downward extension end of the connecting rod 20 and is located between the inner laminate 40 and the outer laminate 50 Below, the outer laminate 50 is provided with a first liquid passage hole and is fixedly connected with the connecting rod 20 through a plurality of radial ribs 51 arranged at intervals in the circumferential direction, and the inner laminate 40 is provided with a secon...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap