A kind of pipe joint joint fireproof structure and construction method for immersed pipe tunnel

A technology of immersed tunnel and construction method, which is applied in basic structure engineering, artificial island, water conservancy engineering and other directions, can solve the problems of fireproofing failure and inability to adapt to the fireproof board, and can prevent impact damage, improve stability, and improve efficiency. Effects of Sex and Reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

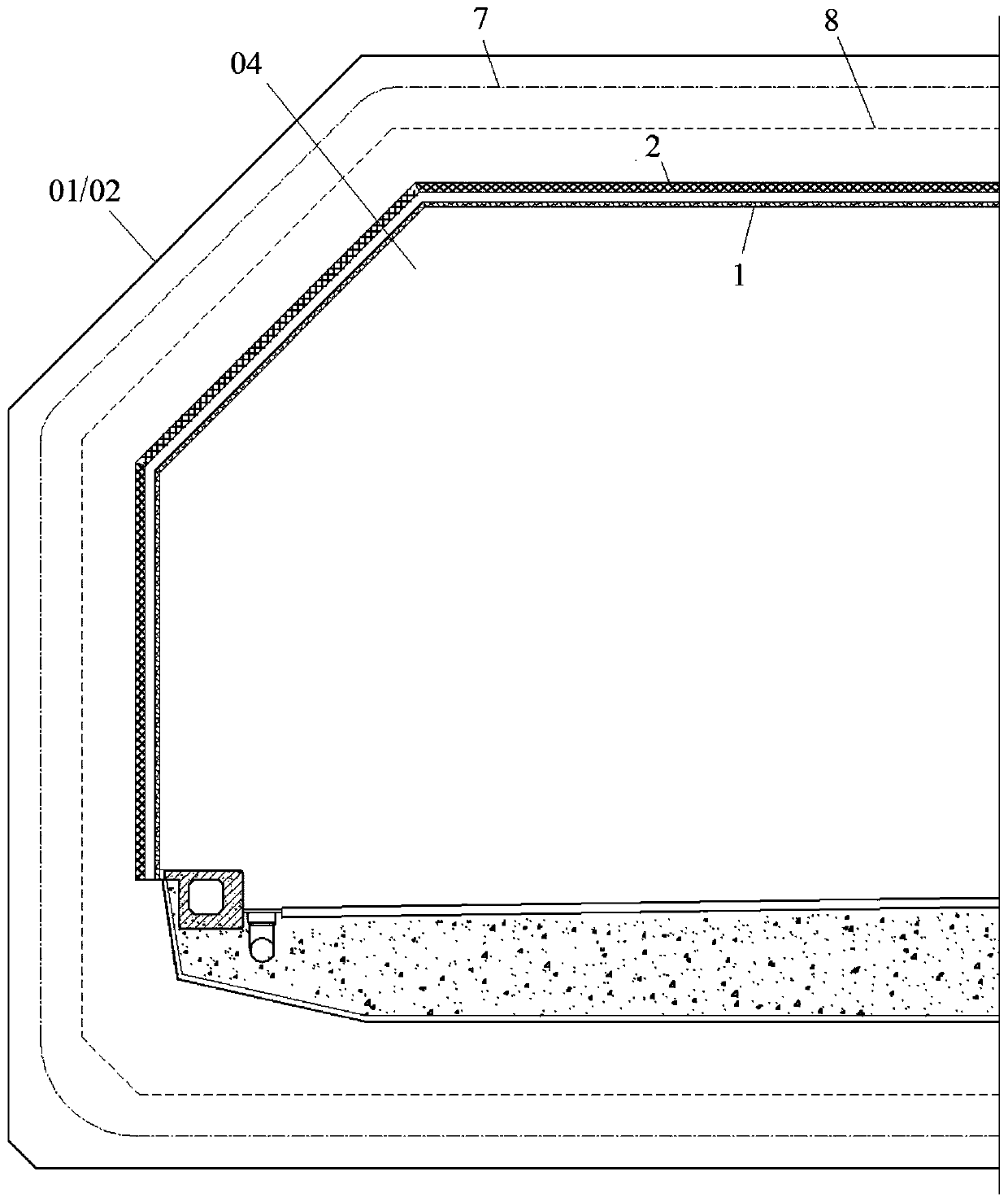

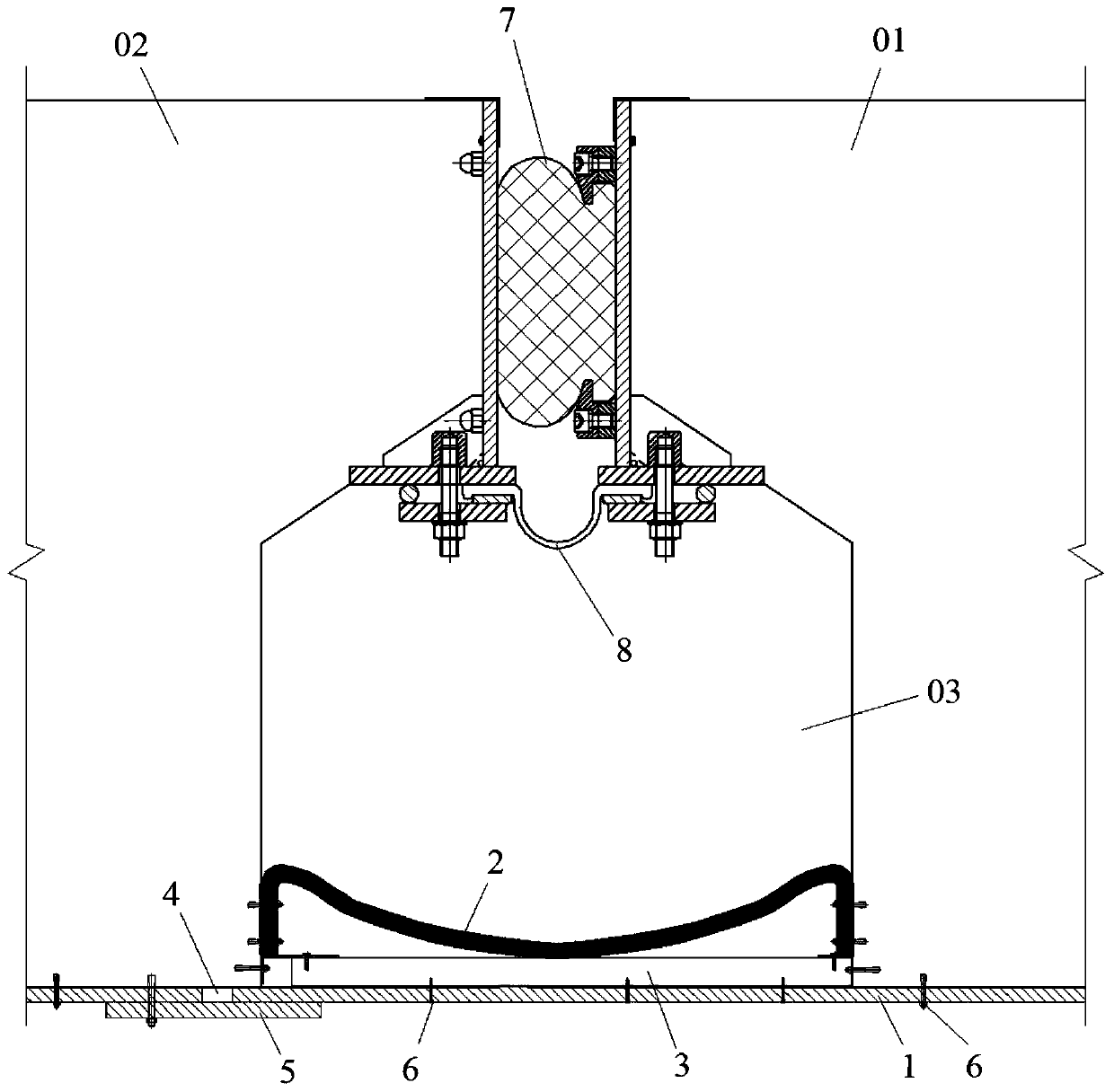

[0039] like figure 1 , 2 , 3, a fireproof structure for pipe joints for immersed tunnels, including:

[0040] A first guard 1, the first guard 1 is a rigid structure, one end of which is used to be fixed on one end of the pipe section 1 01, and the other end is used to be movably connected to the end of the second pipe section 02;

[0041] The second protective member 2, the second protective member 2 is a flexible structural member, one end of which is used to be fixed on one side of the end of the first pipe section 01, and the other end is used to be fixed on the end of the second pipe section 02 side.

[0042]Wherein the above-mentioned second guard 2 is located in the joint cavity 03 enclosed by the first guard 1, the pipe section 1 01 and the pipe section 2 02, so that when an explosion shock occurs in the driving hole 04 of the pipe section, the rigid first The guard 1 protects the flexible structure of the second guard 2. The first fireproof member 1 and the second ...

Embodiment 2

[0050] like Figure 1-3 As shown, the present invention also provides a construction method for the fireproof structure of a pipe joint as described above, comprising the following steps;

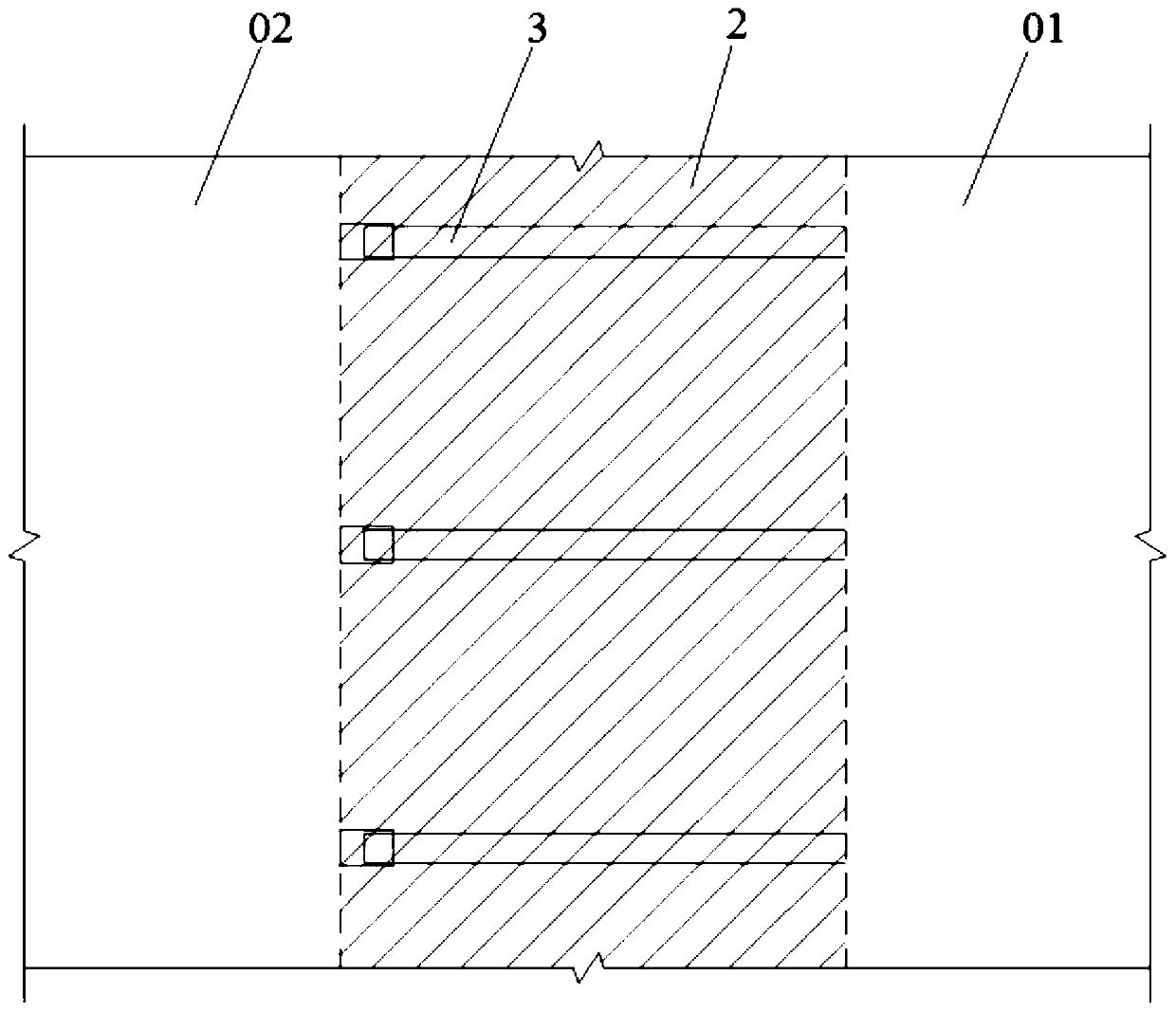

[0051] Step 1: Install the second guard 2, connect the second guard 2 between the end of the pipe section 1 01 and the end of the pipe section 2 02 after the docking is completed, that is, fix one end of the second guard 2 on the pipe section. On the end of one 01, fix the other end on the end of the pipe section two 02;

[0052] Step 2: Install the first guard 1, fix one end of the first guard 1 on the end of the pipe joint 1 01 through the bolt 6, and then movably connect the other end to the pipe joint 2, so that the first guard 1 The other end can slide relative to the end surface of the second pipe section 02 .

[0053] In the above step 2, before installing the first guard 1, connect the support 3 between the end of the pipe section 1 01 and the end of the pipe section 2 02, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com