Honeycomb column of core steel structure

A steel structure, honeycomb technology, applied in the direction of columns, piers, pillars, etc., can solve the problems of shortening the construction period, single structural system, etc., and achieve the effect of convenient assembly and transportation, high strength, and increased overall strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

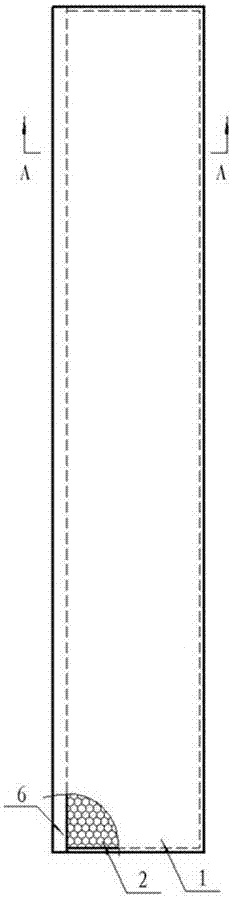

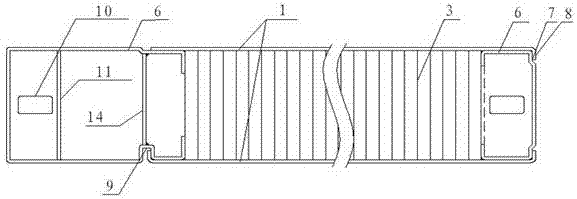

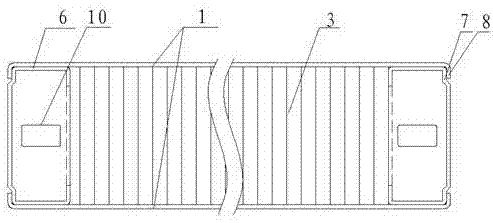

[0044] Such as Figure 1~Figure 2 As shown in Figure 13, a core steel structure honeycomb column 101 is composed of a metal honeycomb panel 1. The metal honeycomb panel 1 includes a honeycomb core 2 and panels 3 welded on both sides of the honeycomb core 2. The honeycomb core 2 is folded and formed A thin sheet, a connection layer 4 is provided between the honeycomb core 2 and the panel 3, the connection layer 4 is formed by brazing, the honeycomb core 2 is a thin sheet folded into a plurality of through holes 5, the through holes 5 are hexagonal, The panel 3 is made of stainless steel, and the sheet 5 is made of stainless steel foil. Flanges 8 are provided around the panel 3 , and frames 6 are provided on both sides of the honeycomb column 101 .

[0045] The frame 6 on one side of the honeycomb column 101 is a channel steel, and the channel steel is provided with a concave edge 7 , and the concave edge 7 is welded with the folded edge 8 of the panel 3 . The concave depth of...

Embodiment 2

[0049] Such as Figure 1~Figure 3 As shown in Figure 13, Embodiment 2 is roughly the same as Embodiment 1, the difference being that the frames 6 on both sides of the honeycomb column 101 are all channel steel, the channel steel is provided with a concave edge 7, and the folding of the concave edge 7 and the panel 3 Sides 8 are welded together. The concave depth of the recessed edge 7 is equal to the thickness of the folded edge 8 , so that the outer surface of the frame 6 is flush with the outside of the folded edge 8 .

Embodiment 3

[0051] Such as Figure 4 As shown, a single honeycomb column 101 forms a "one"-shaped column. It can be understood that two or more honeycomb columns 101 are connected in a straight line to form a "one"-shaped column.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com