Ice slurry making system with variable evaporation area

A technology of evaporation area and liquid ice, which is applied in ice making, ice making, lighting and heating equipment, etc. It can solve the problems of low efficiency of refrigeration system, slow refrigeration speed, unreasonable configuration of refrigeration system, etc., and achieve floor space saving , The effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following descriptions of the preferred embodiments are only illustrative in nature, and are not meant to limit the invention, nor to limit the application of the invention.

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

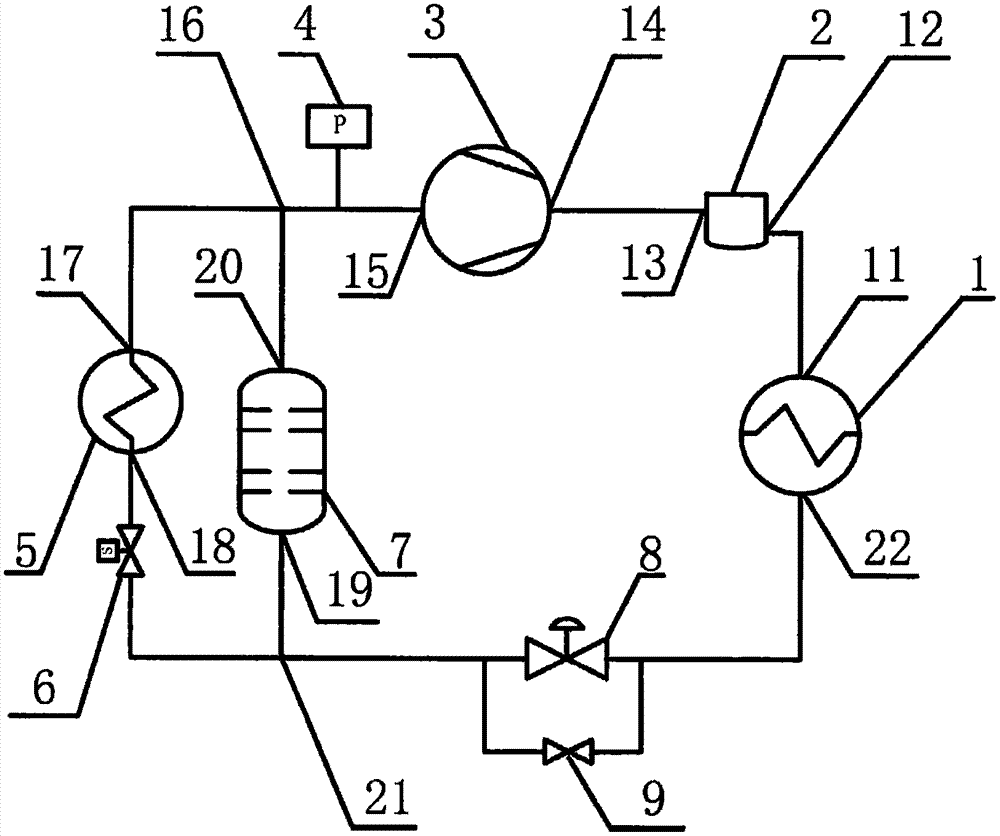

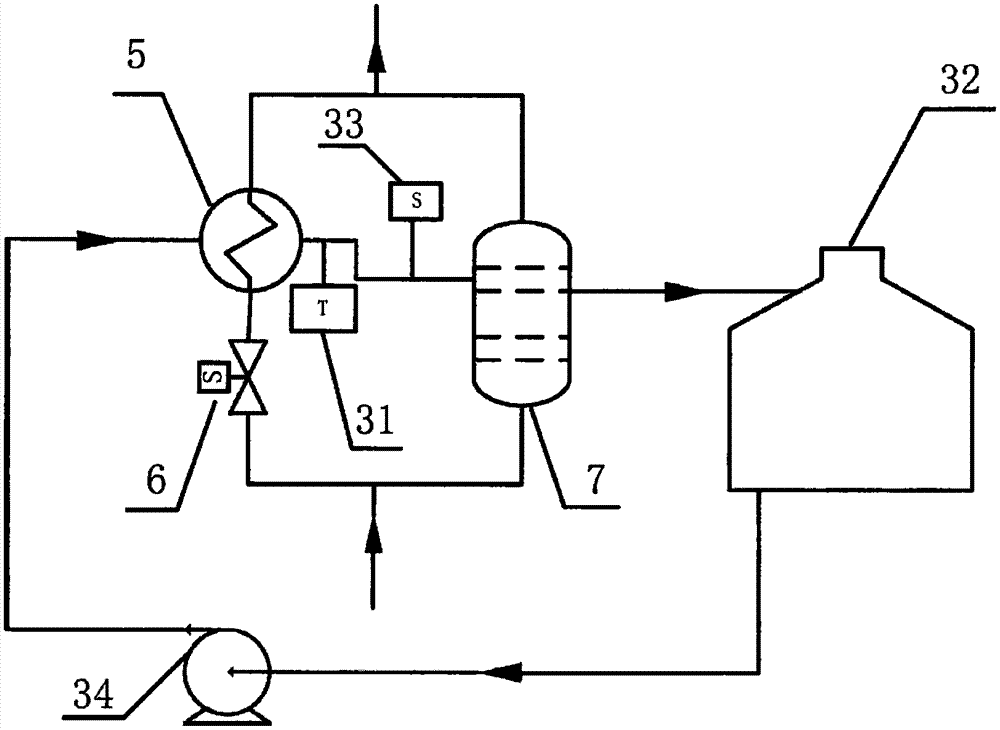

[0035] The present invention comprises three parts, and the first part is refrigeration cycle system, and its arrangement form is as follows figure 1 ——Schematic diagram of the ice-making system of fluid ice with variable evaporation area; the second part is the ice-making circulation system; the third part is the cooling water circulation system.

[0036] Such as figure 1 ——As shown in the schematic diagram of the liquid ice ice-making system with variable evaporation area, the refrigeration compressor (3) compresses the refrigerant to form a high-temperature and high-pressure refrigerant gas, which enters the oil separator (2) through the gas outlet (14) o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com