Star (Y) connection high voltage electric motor insulating detection apparatus

A high-voltage motor, detection device technology, applied in the direction of measurement device, motor generator test, high resistance measurement, etc., can solve problems such as loss, cumbersome, damaged equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

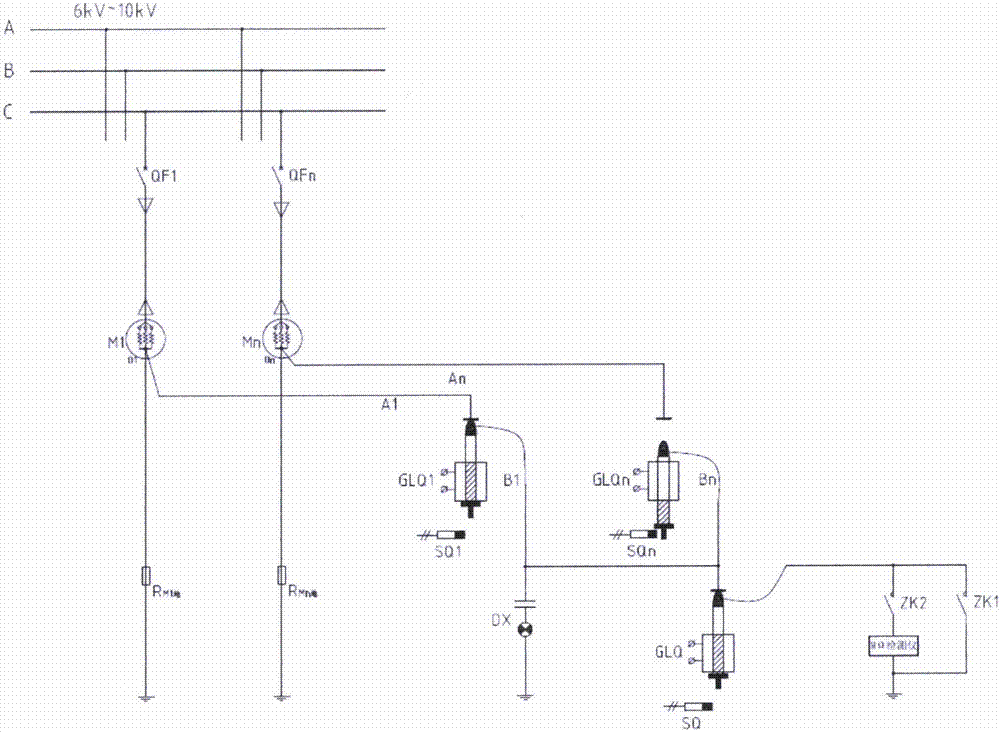

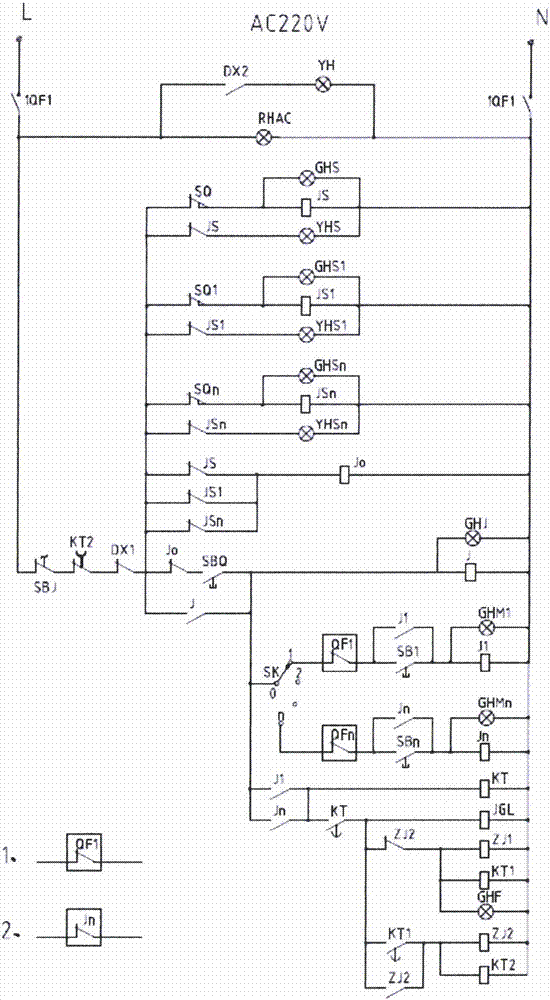

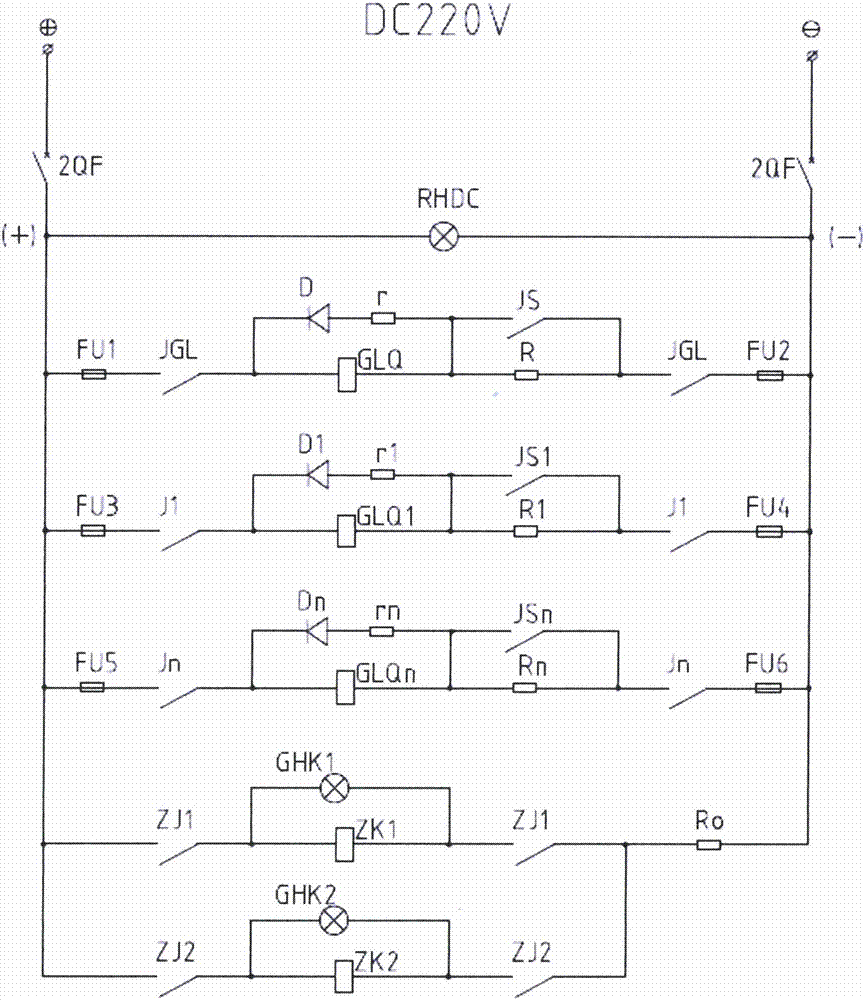

[0035] Star (Y) connection high-voltage motor insulation detection device, composed of figure 1 Main circuit schematic diagram of star (Y) connection high voltage motor insulation detection device, figure 2 Schematic diagram of the AC control circuit of the star (Y) connection high-voltage motor insulation detection device, image 3 The composition of the DC control circuit schematic diagram of the star (Y) connection high-voltage motor insulation detection device, in which figure 2 is the core of operational control, figure 1 , 3 are subject to figure 2 control through figure 2 ,Bundle figure 1 image 3 Insulation detection device with close relationship is formed between the operation control box (cabinet) DKX, the cabinet surface is arranged with indicator lights, buttons and MΩ detector, the electrical appliances in the box are arranged and installed in partitions and connected through terminals, and the control box (cabinet) DKX is connected with external cables...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com