High-dispersity and high-stability octadecyl amine emulsion processing equipment and process

A technology with high stability and processing technology, applied in the direction of dissolution, mixer, dissolution, etc., can solve the problems that the technology cannot meet the practical application well, the safety doubt of octadecylamine emulsion, and the inability to judge the influence of additives, etc., to achieve equipment Low process cost, improved mechanical shear force, and the effect of preventing acid corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

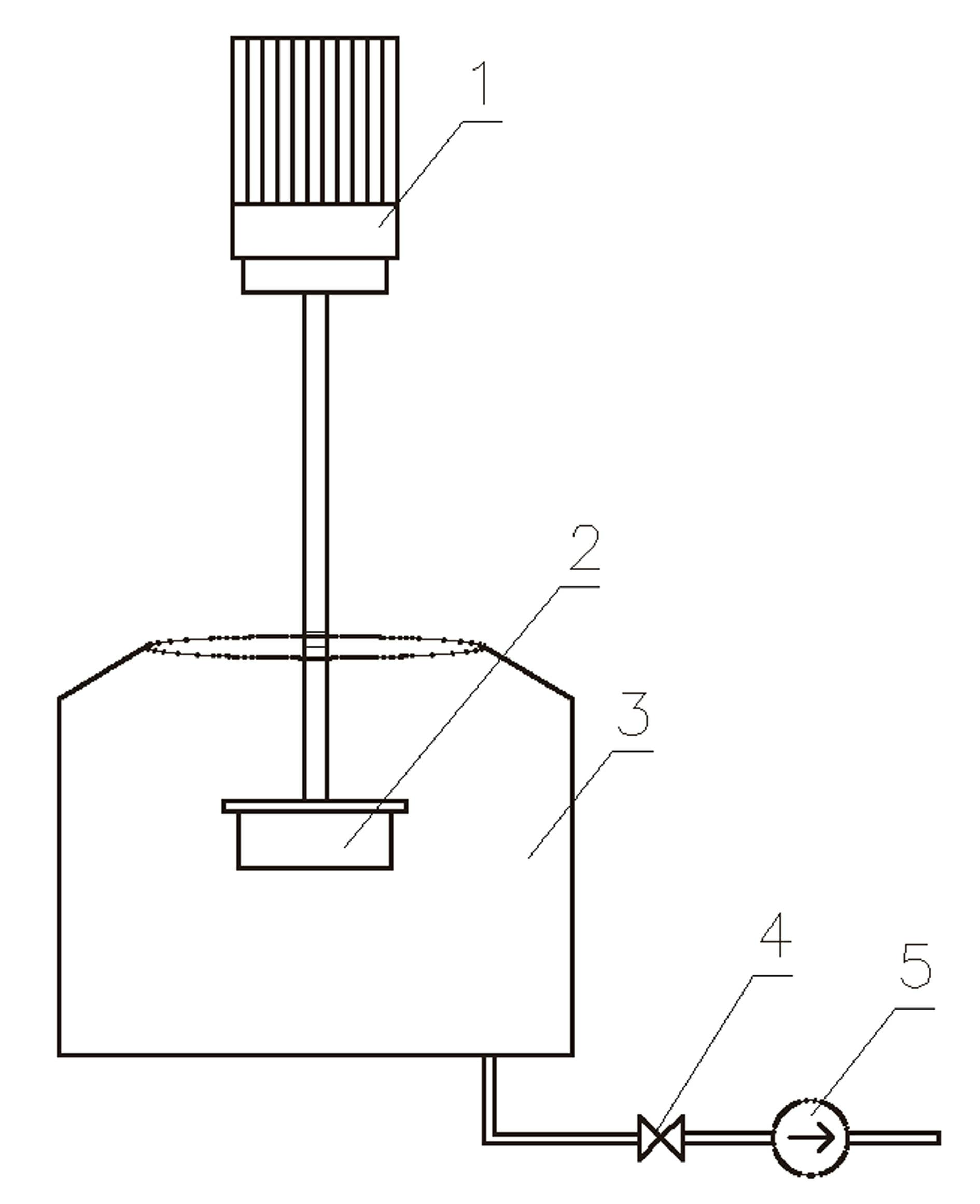

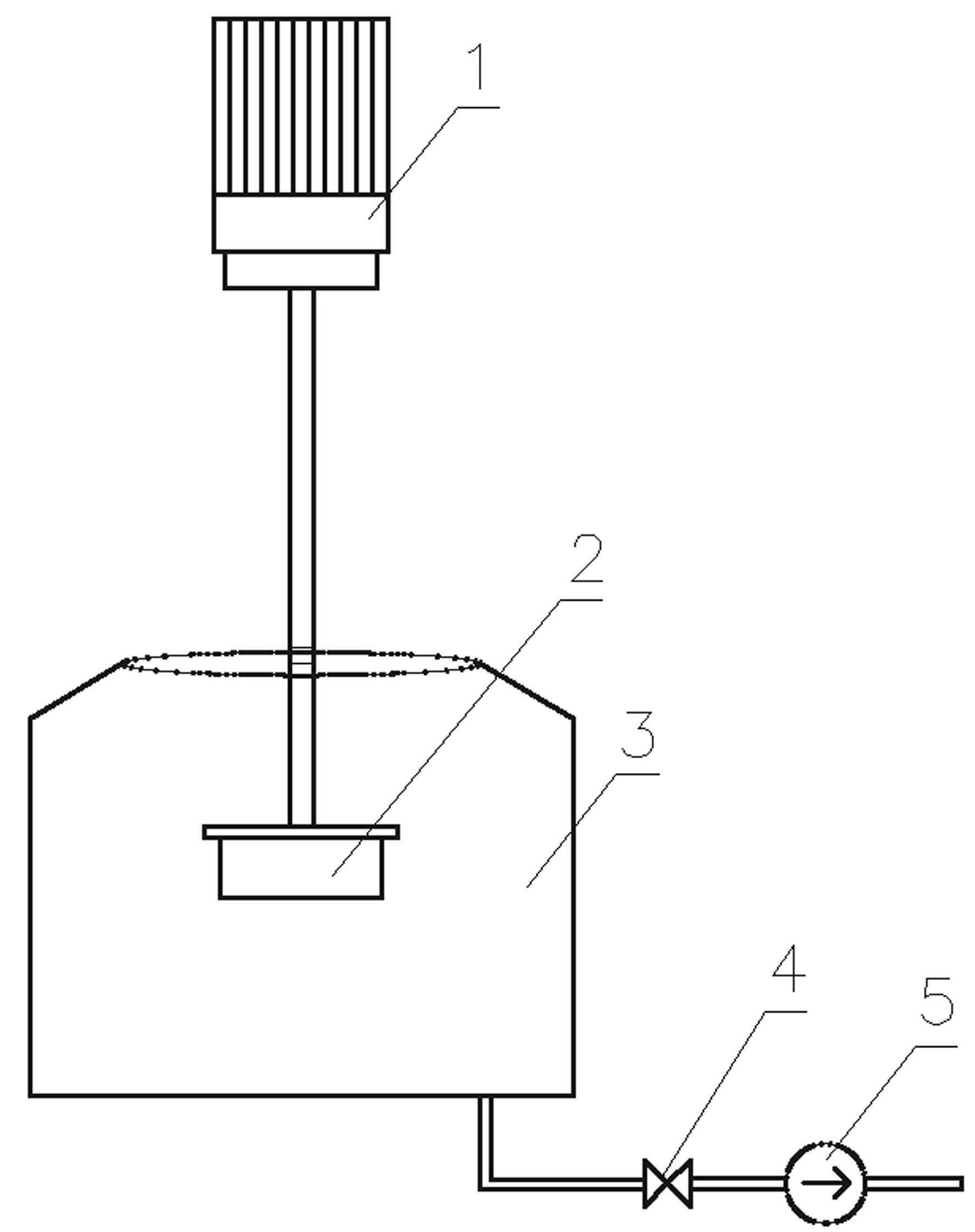

[0030] The present invention and its beneficial effects will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0031] refer to figure 1 , a kind of high-dispersion, high-stability octadecylamine emulsion processing equipment, comprising open container 3, discharge valve 4 and self-priming pump 5 are successively installed on the discharge pipeline at the bottom of said container 3, utilize self-priming pump The unique suction effect makes the emulsion filling speed 3-5 times higher than that of the self-flowing method. When preparing the emulsion, the high-shear stirring head 2 of the high-shear mixing emulsifier is placed in the container 3 , and the high-shear stirring head 2 is driven by the motor 1 .

[0032] A kind of high dispersion, the processing technology of high stability octadecylamine emulsion, it comprises following operating process:

[0033] (1) In a clean and open container, inject 475, 500, 525, 550, 575 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com