Cutter for machine clamping cutting of round or ring-shaped sealing gasket

A sealing washer, annular technology, which is applied in the parts of boring machine/drilling machine, drilling/drilling equipment, drilling tool accessories, etc. problem, to achieve the effect of wide range of use, easy to carry and easy to maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

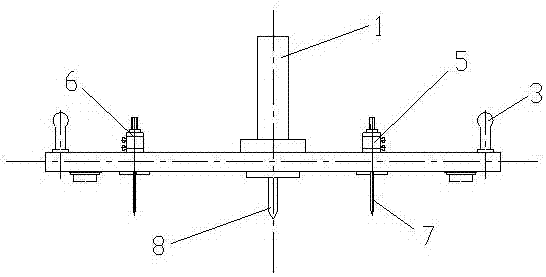

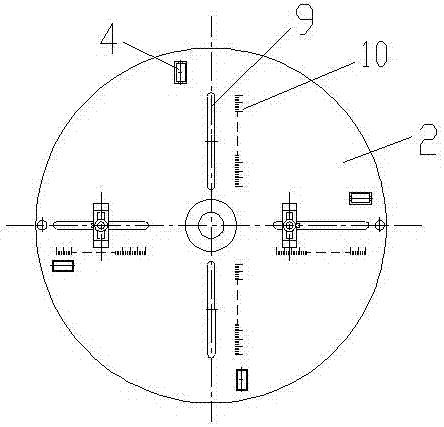

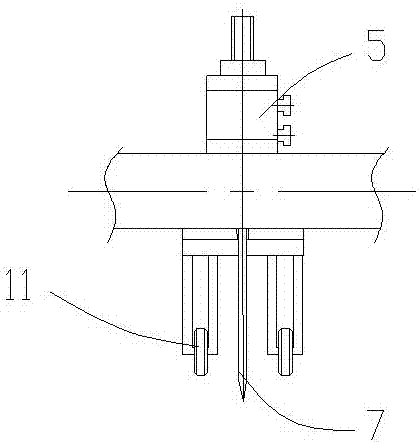

[0021] see figure 1 , figure 2 , the present embodiment is a cutting knife for cutting circular or annular sealing gaskets with a machine clamp. According to the size of the sealing gaskets commonly used in enterprises, a cutting knife fixing disc 2 is set, and the upper part of the center of the cutting knife fixing disc 2 is a machine clamping handle bar. 1. A positioning pin 8 is installed on the bottom end of the clamp handle rod 1, and the positioning pin 8 has an up and down height adjustment mechanism. The height adjustment mechanism of the locating pin 8 is realized by the sleeve magnetically attracting the locating pin or tightening the set screw, and also can adopt the structure form of the drill sleeve. Further, the bottom end of the clamp handle bar 1 has a quadrangular hole structure, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com