Sludge energy modification system

A technology for energy and sludge, which is applied in the fields of sludge detoxification, sludge treatment, water/sludge/sewage treatment, etc., to facilitate large-scale popularization and use, eliminate heavy metal pollution, and promote combustion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

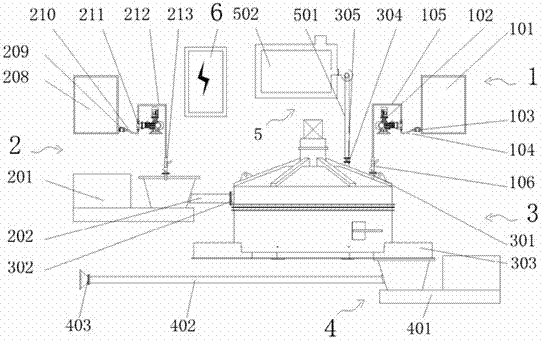

[0029] refer to figure 1 , the present embodiment includes a modifier adding distributing device 1, a sludge feeding device 2, a sludge modified mixing device 3, a modified sludge distributing device 4, a poly-exhaust gas treatment device 5 and an electric control device 6; the sludge The mud modification and mixing device 3 is provided with a modifier feeding port 301, a sludge feeding port 302, a discharge port 303, and a gas gathering port 304, and the gas collecting port 304 is connected to the gas collecting port 305 through the gas collecting and exhausting pipeline valve 305. The gas treatment device 5 is connected, the modifier feeding device 1 is connected to the modifier feeding port 301, the sludge feeding device 2 is connected to the sludge feeding port 302, and the modified sludge feeding device 4 is connected to the discharge port The feed port 303 is connected, and the electric control device 6 is respectively connected to the modifier adding distributing device...

Embodiment 2

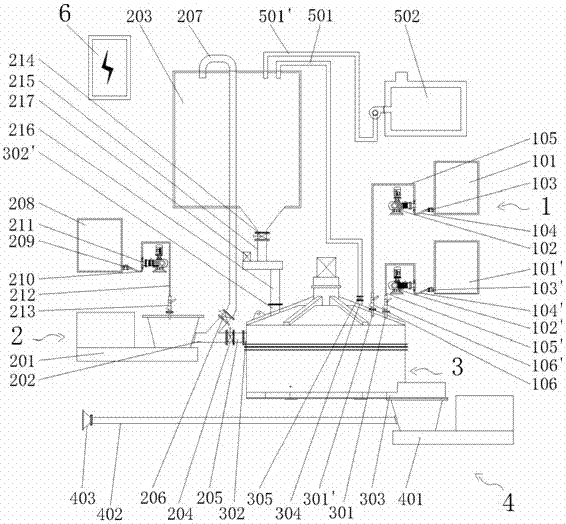

[0041] refer to figure 2 , the difference between this embodiment and embodiment 1 is:

[0042] (1) There is a second modifier adding distributing device, the second modifier adding distributing device includes a second modifier tank 101', a second modifier meter feed pump 102', a second modifier Agent pipeline valve 103', second modifier pipeline I 104', second modifier pipeline II 105' and second modifier adding distributor 106', the second modifier tank 101' is connected to the second modifier The agent pipeline valve 103' is connected, and the second modifier pipeline valve 103' is connected with the second modifier pipeline I104', and the second modifier pipeline I104' is connected with the second modifier meter feeding pump 102 ' connected, the second modifier meter feed pump 102' is connected to the second modifier pipeline II 105', and the second modifier pipeline II 105' is connected to the second modifier adding distributor 106'; Correspondingly, a second modifier...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com