High-electromechanical-transformation multiphase piezoelectric ceramic material applied to energy collection device and preparation method

A technology of piezoelectric ceramics and energy harvesting, which is applied in the field of piezoelectric ceramic materials, can solve problems such as the difficulty in meeting the application requirements of high-performance piezoelectric energy harvesters, the limited range of energy conversion coefficient improvement, and unfavorable material conversion coefficients. Significant economic and social value, easy operation, and the effect of improving electromechanical conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

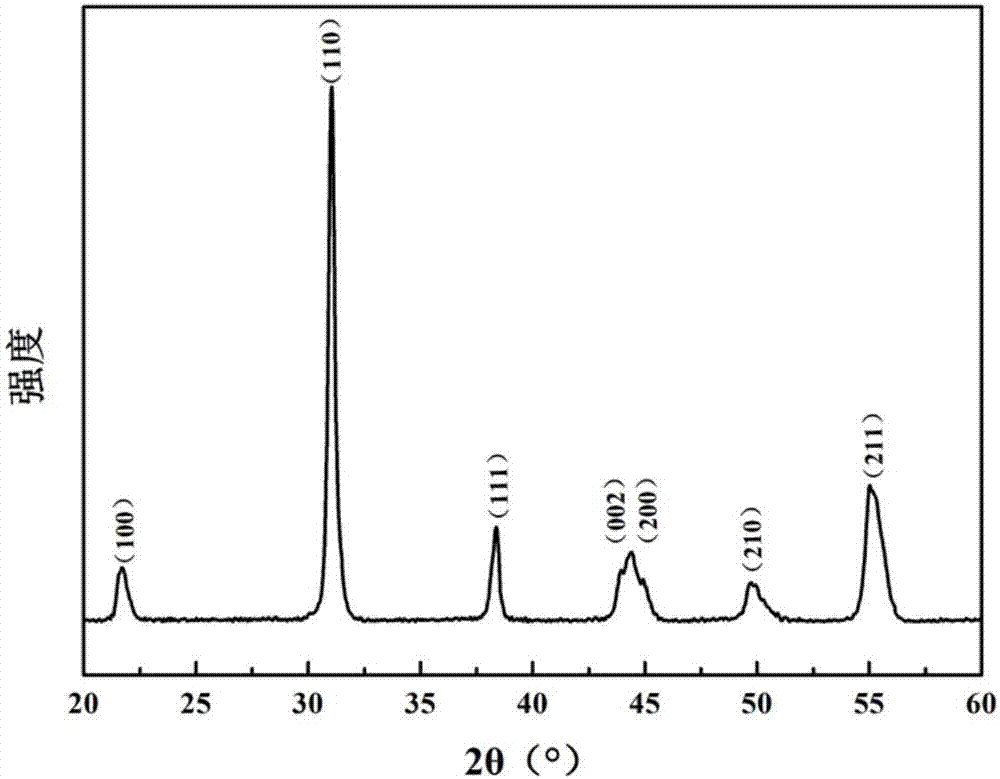

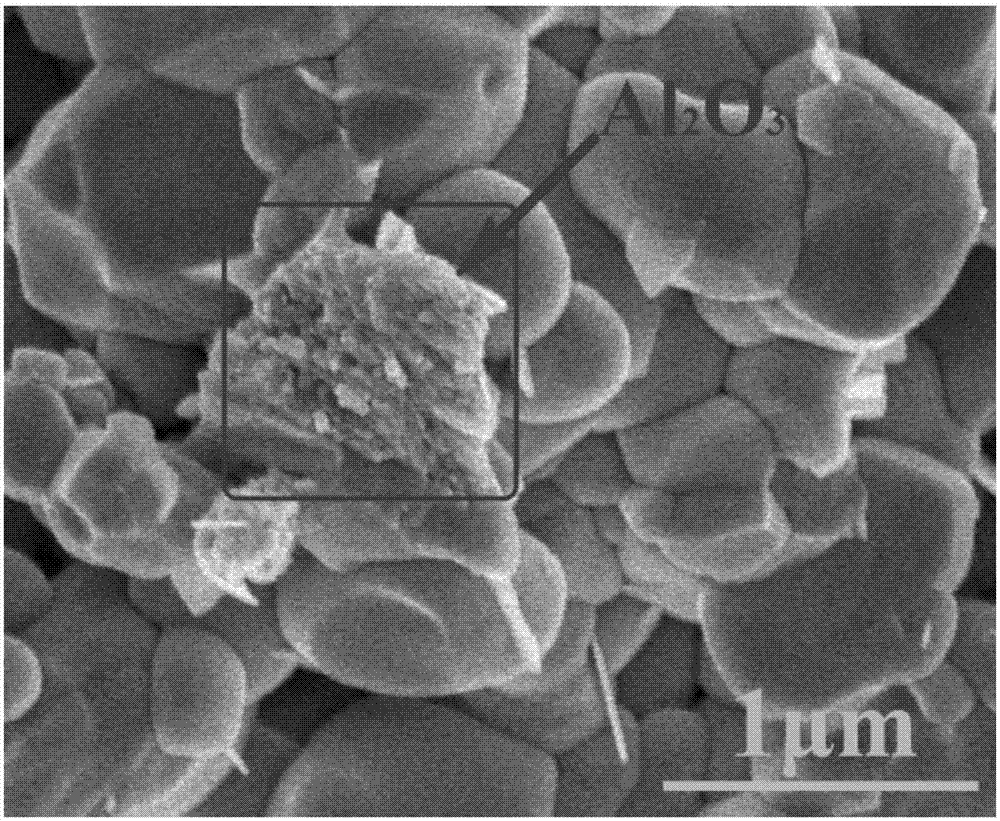

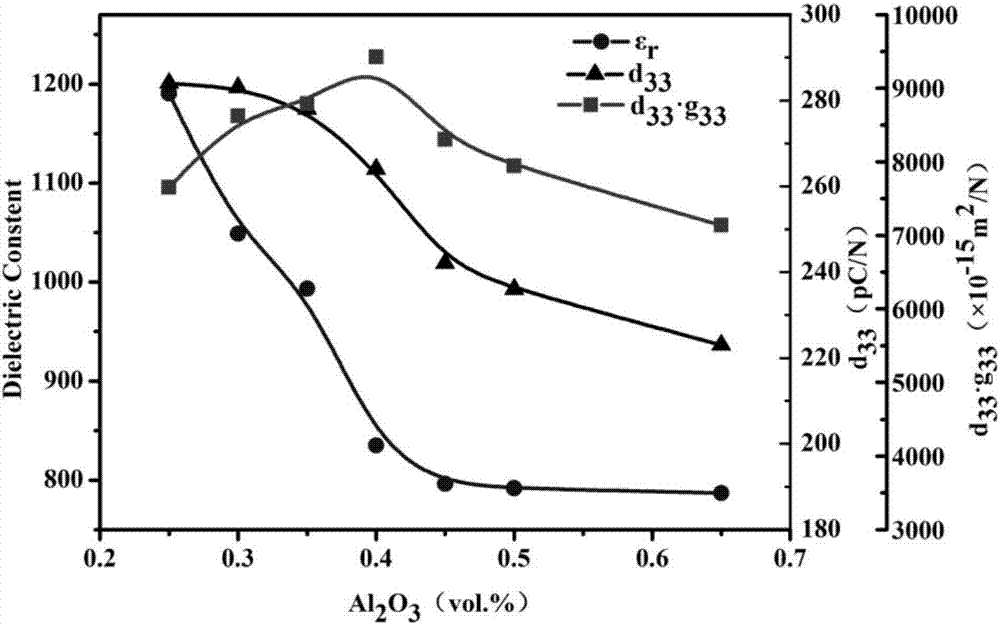

[0034] First according to the matrix chemical formula 0.2Pb(Zn 1 / 3 Nb 2 / 3 )O 3 -0.8Pb(Zr 1 / 2 Ti 1 / 2 )O 3 Weigh Nb 2 o 5 , Pb 3 o 4 , ZrO 2 、TiO 2 and ZnO, and ball milled in ethanol for 12 hours. The mixture was dried and calcined at 850°C for 2 hours, ball milled in ethanol and dried again to obtain 0.2PZN-0.8PZT matrix powder. Then press 99.75vol.%[0.2PZN-0.8PZT] / 0.25vol. %Al 2 o 3 Composition, weighing 0.2PZN-0.8PZT and Al 2 o 3 , and ball milled in ethanol for 12 hours, the mixture was dried and mixed according to the ratio of 10g powder and 1.5mL binder, and the molding was pressed at 100MPa. hours to get ceramics.

Embodiment 2

[0036] According to 99.70vol.%[0.2PZN-0.8PZT] / 0.30vol.%Al 2 o 3 Composition, weighing 0.2PZN-0.8PZT and Al 2 o 3 . Others are with embodiment 1.

Embodiment 3

[0038] According to 99.65vol.%[0.2PZN-0.8PZT] / 0.35vol.%Al 2 o 3 Composition, weighing 0.2PZN-0.8PZT and Al 2 o 3 . Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com