Liquid cage-shaped silsesquioxane and preparation method thereof

A silsesquioxane and cage technology, applied in the field of liquid cage silsesquioxane and its preparation, can solve the loss performance, poor thermal and mechanical properties of epoxy resin, poor compatibility and dispersibility, etc. problems, to achieve the effect of improving compatibility and dispersion, improving thermal and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

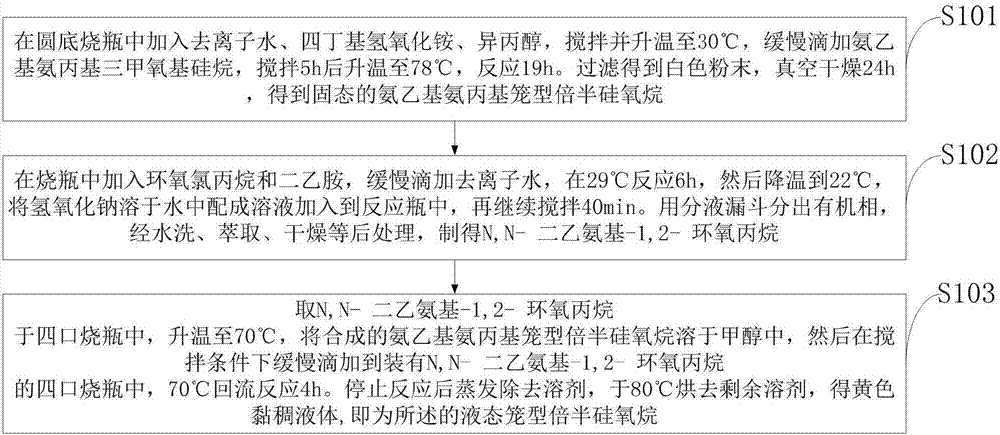

[0025] like figure 1 As shown, the preparation method of liquid cage silsesquioxane provided by the embodiments of the present invention specifically includes:

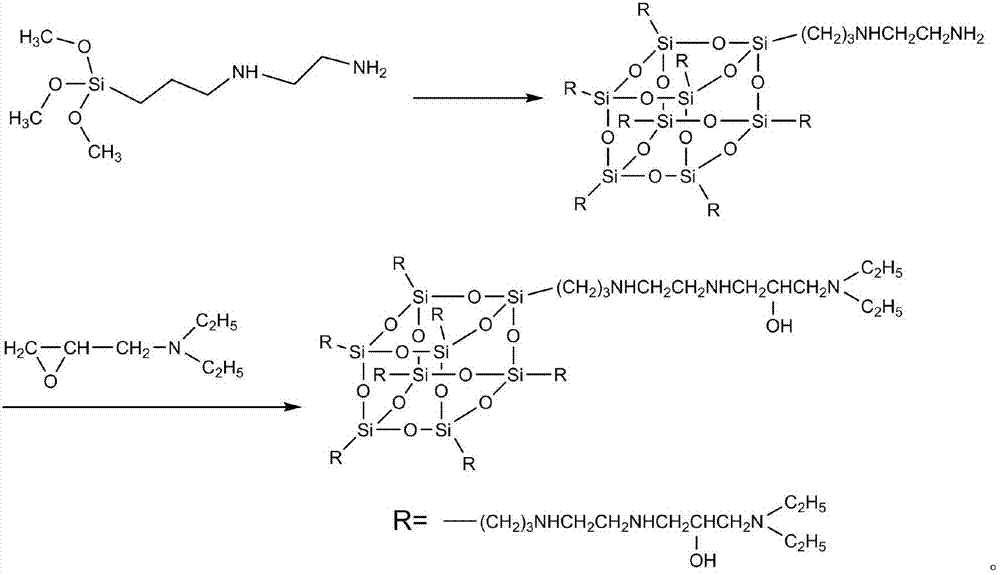

[0026] S101: Add deionized water, tetrabutylammonium hydroxide, and isopropanol into a round-bottomed flask, stir and heat up to 30°C, slowly add aminoethylaminopropyltrimethoxysilane dropwise, stir for 5 hours, then heat up to 78°C, Reaction 19h. The white powder was obtained by filtration, and dried in vacuum for 24 hours to obtain solid aminoethylaminopropyl cage silsesquioxane.

[0027] S102: Add epichlorohydrin and diethylamine to the flask, slowly add deionized water dropwise, react at 29°C for 6h, then cool down to 22°C, dissolve sodium hydroxide in water to make a solution and add it to the reaction flask, Stirring was continued for another 40 min. Separate the organic phase with a separatory funnel, wash with water, extract and dry to obtain N,N-diethylamino-1,2-propylene oxide.

[0028] S103: Take N,N-di...

Embodiment 1

[0034] (1) Add 10g of deionized water, 0.21g of tetrabutylammonium hydroxide, and 31g of isopropanol into a 500ml round bottom flask, stir and heat up to 30°C, slowly add 40.25g of aminoethylaminopropyltrimethoxysilane dropwise, After stirring for 5 hours, the temperature was raised to 78°C, and the reaction was carried out for 19 hours. The white powder was obtained by filtration, and dried in vacuum for 24 hours to obtain solid aminoethylaminopropyl cage silsesquioxane.

[0035] (2) Add 18.5g epichlorohydrin and 14.4 diethylamine into a 250ml round bottom flask, slowly add 6g deionized water dropwise, react at 29°C for 6h, then cool down to 22°C, dissolve 8g sodium hydroxide in 15.2 mL of water was made into a solution and added to the reaction flask, and the stirring was continued for 40 minutes. Separate the organic phase with a separatory funnel, wash with water, extract and dry to obtain N,N-diethylamino-1,2-propylene oxide.

[0036] (3) Take 2.54g of N,N-diethylamino-...

Embodiment 2

[0039] (1) Add 10g of deionized water, 0.21g of tetrabutylammonium hydroxide, and 31g of isopropanol into a 500ml round bottom flask, stir and heat up to 30°C, slowly add 40.25g of aminoethylaminopropyltrimethoxysilane dropwise, After stirring for 5 hours, the temperature was raised to 78°C, and the reaction was carried out for 19 hours. The white powder was obtained by filtration, and dried in vacuum for 24 hours to obtain solid aminoethylaminopropyl cage silsesquioxane.

[0040] (2) Add 18.5g epichlorohydrin and 14.4 diethylamine into a 250ml round bottom flask, slowly add 6g deionized water dropwise, react at 29°C for 6h, then cool down to 22°C, dissolve 8g sodium hydroxide in 15.2 mL of water was made into a solution and added to the reaction flask, and the stirring was continued for 40 minutes. Separate the organic phase with a separatory funnel, wash with water, extract and dry to obtain N,N-diethylamino-1,2-propylene oxide.

[0041] (3) Take 2.54g of N,N-diethylamino-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com