Microwave self-repairable polypropylene-carbon-based composite material and preparation method thereof

A technology of carbon-based composite materials and carbon-based materials, applied in the field of polypropylene-carbon-based composite materials and their preparation, to achieve good self-healing effects, improve dispersion and compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

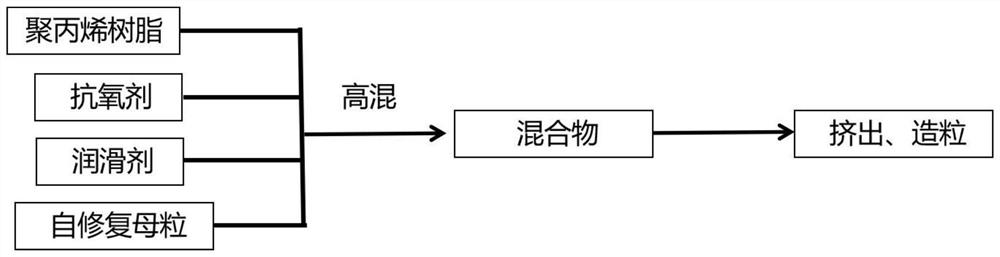

Method used

Image

Examples

Embodiment 1

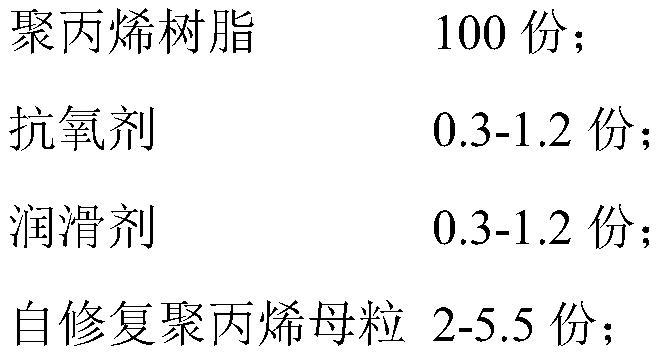

[0097] A microwave self-healing polypropylene-carbon-based composite material is prepared from the following components by weight:

[0098]

[0099] The preparation method of self-healing polypropylene masterbatch is as follows:

[0100]1) Mix 2000-mesh carbon black and phenyltrimethoxysilane in a mixer at a mass ratio of 5:1, the speed of the mixer is 200r / min, and the mixing time is 2min;

[0101] 2) Continue to add polypropylene powder to the mixer, the mass ratio is 1:2 according to the total mass of the material in step 1) and the polypropylene powder (the particle size is 0.1mm, the melt index is 20g / 10min), and then Continue to mix with a mixer, the speed of the mixer is 200r / min, and the mixing time is 2min;

[0102] 3) The mixed material in step 2) is fed into the twin-screw extruder through the main feeder, then melted and extruded, and granulated to obtain self-repairing polypropylene masterbatch.

[0103] The process parameters of the twin-screw extruder are a...

Embodiment 2

[0108] A microwave self-healing polypropylene-carbon-based composite material is prepared from the following components by weight:

[0109]

[0110] The preparation method of self-healing polypropylene masterbatch is as follows:

[0111] 1) Mix 2000-mesh carbon black and phenyltrimethoxysilane in a mixer at a mass ratio of 5:1, the speed of the mixer is 200r / min, and the mixing time is 2min;

[0112] 2) Continue to add polypropylene powder to the mixer, the mass ratio is 1:2 according to the total mass of the material in step 1) and the polypropylene powder (the particle size is 0.1mm, the melt index is 20g / 10min), and then Continue to mix with a mixer, the speed of the mixer is 200r / min, and the mixing time is 2min;

[0113] 3) The mixed material in step 2) is fed into the twin-screw extruder through the main feeder, then melted and extruded, and granulated to obtain self-repairing polypropylene masterbatch.

[0114] The process parameters of the twin-screw extruder are ...

Embodiment 3

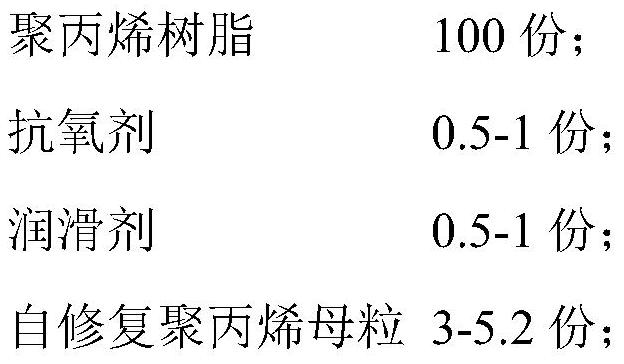

[0119] A microwave self-healing polypropylene-carbon-based composite material is prepared from the following components by weight:

[0120]

[0121] The preparation method of self-healing polypropylene masterbatch is as follows:

[0122] 1) Mix 2000-mesh carbon black and phenyltrimethoxysilane in a mixer at a mass ratio of 5:1, the speed of the mixer is 200r / min, and the mixing time is 2min;

[0123] 2) Continue to add polypropylene powder to the mixer, the mass ratio is 1:2 according to the total mass of the material in step 1) and the polypropylene powder (the particle size is 0.1mm, the melt index is 20g / 10min), and then Continue to mix with a mixer, the speed of the mixer is 200r / min, and the mixing time is 2min;

[0124] 3) The mixed material in step 2) is fed into the twin-screw extruder through the main feeder, then melted and extruded, and granulated to obtain self-repairing polypropylene masterbatch.

[0125] The process parameters of the twin-screw extruder are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Melt finger | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com