Transparent polyimide film and preparation method thereof

A technology of polyimide film and transparent polyimide, applied in the field of transparent polyimide film and its preparation, can solve the problems of increased expansion or shrinkage, influence of electronic device performance, and high polyimide film , to reduce thermal expansion coefficient, improve thermal dimensional stability and mechanical modulus, and make film formation easier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

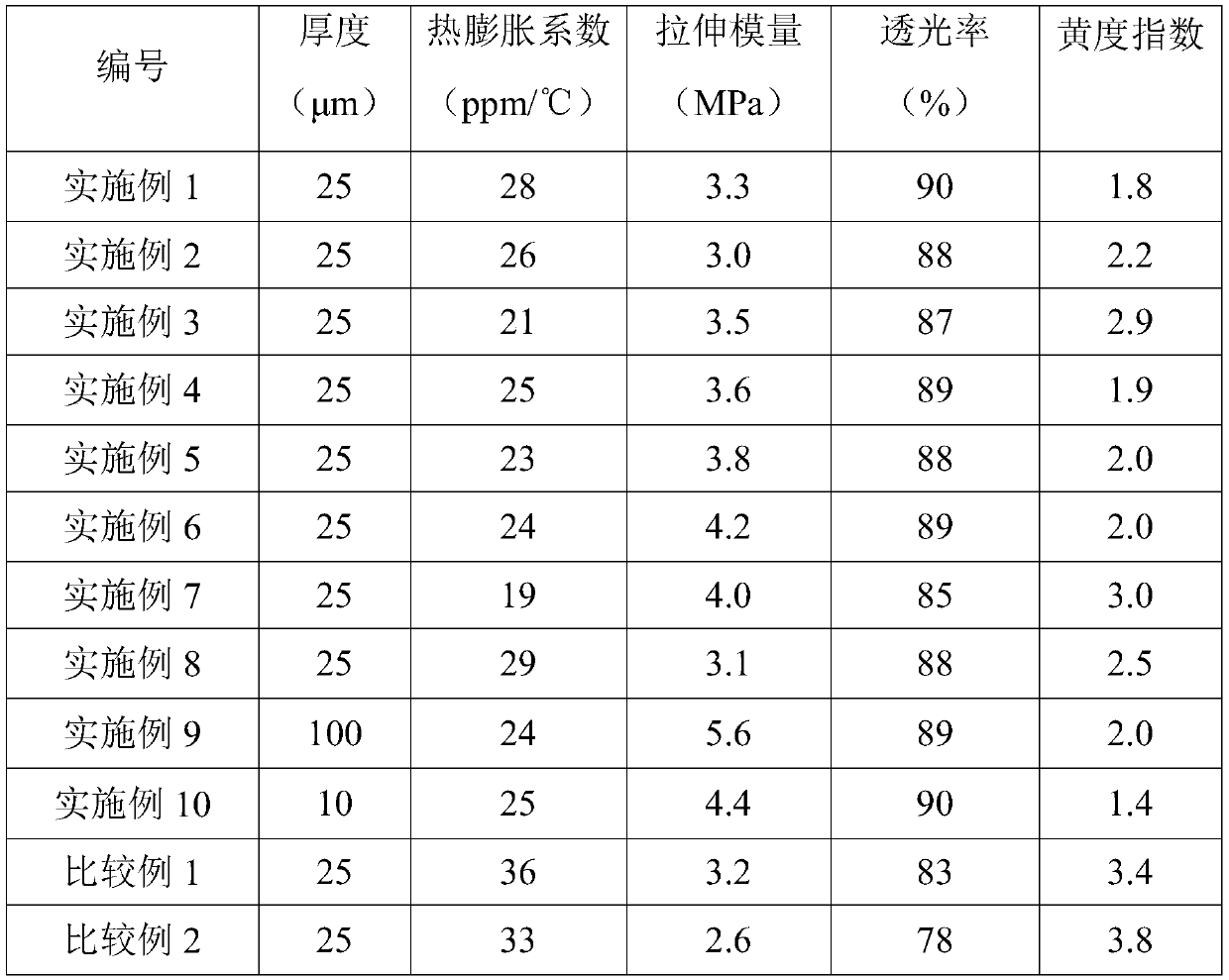

Embodiment 1

[0035] (1) Uniformly disperse 0.095g of small particle size silica (particle size: 10nm) and 0.0094g of large particle size silica (particle size: 30nm) in 0.4176g of N,N-dimethylacetamide, Silica sol was prepared. Add it into a three-necked flask, continue to add 0.125 g of heptafluoropentyltriethoxysilane, start stirring and heat to 100° C. After 2 hours of reaction, stop heating and cool down to room temperature.

[0036] (2) Add 910g of N,N-dimethylacetamide and 96.07g (0.3mol) of 2,2'-bis(trifluoromethyl)-4,4'-diaminobiphenyl to the above reaction system, After dissolving, add 133.27g (0.3mol) of 2,2-bis(3,4-dicarboxyphenyl)hexafluoropropane dianhydride, control the reaction temperature at 0-30°C, and react for 6 hours to prepare a polyamic acid solution. Adjust the solid content of the system to be about 20wt%, and the viscosity at 25°C is 140000cP.

[0037] (3) Coat the polyamic acid solution prepared above on a glass substrate, dry at 180°C for 20 minutes, then gradu...

Embodiment 2

[0039] (1) 2.00g of small particle size silica (particle size: 5nm) and 0.04g of large particle size silica (particle size: 10nm) were uniformly dispersed in 8.164g of N,N-dimethylacetamide, Silica sol was prepared. Add it into a three-necked flask, continue to add 2.449g of perfluorooctylethyltriethoxysilane, start stirring and heat to 100°C, stop heating after 2 hours of reaction, and cool down to room temperature.

[0040] (2) Add 820g of N,N-dimethylacetamide and 100.27g (0.3mol) of 2,2'-bis(4-aminophenyl)hexafluoropropane to the above reaction system, and add 119.94g after dissolving (0.27mol) 2,2-bis(3,4-dicarboxyphenyl)hexafluoropropane dianhydride, control the reaction temperature at 0-30°C, and react for 6 hours to prepare a polyamic acid solution. Adjust the solid content of the system to be about 20wt%, and the viscosity at 25°C is 100000cP.

[0041] (3) Coat the polyamic acid solution prepared above on a glass substrate, dry at 180°C for 20 minutes, then graduall...

Embodiment 3

[0043] (1) Evenly disperse 0.618g of small particle size silica (particle size: 10nm) and 0.031g of large particle size silica (particle size: 20nm) in 2.596g of N,N-dimethylacetamide, Silica sol was prepared. Add it into a three-necked flask, continue to add 0.779g of heptafluoropentyltriethoxysilane, start stirring and heat to 100°C, stop heating after 2 hours of reaction, and cool down to room temperature.

[0044] (2) Add 850g of N,N-dimethylacetamide and 155.53g (0.3mol) of 2,2'-bis[4(3-aminophenoxy)phenyl)]hexafluoropropane to the above reaction system After dissolving, add 17.65g (0.06mol) biphenyltetracarboxylic dianhydride, 111.06g (0.25mol) 2,2-bis(3,4-dicarboxyphenyl) hexafluoropropane dianhydride, control the reaction temperature at 0 ~30°C, after reacting for 6 hours, a polyamic acid solution was prepared. Adjust the solid content of the system to be about 20wt%, and the viscosity at 25°C is 80000cP.

[0045] (3) Coat the polyamic acid solution prepared above o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com