Reflective heat-insulating coating

A reflective heat-insulating coating and modification technology, applied in the field of decorative coatings, can solve the problems of the tensile strength and elongation at break of the coating film to be improved, the use cost is high, and it is easy to fall off, so as to improve the smoothness of spraying and the uniformity of the coating. properties, and the effect of improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

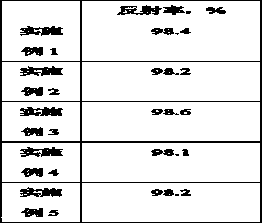

Examples

Embodiment 1

[0031] A reflective heat-insulating coating, the composition of which is as follows in parts by mass: 20 parts of water, 10 parts of acrylic emulsion, 16 parts of surface-coated modified ultrafine hollow glass microspheres, 10 parts of rutile titanium dioxide, 10 parts of elastic emulsion, and 2 parts of cellulose , 0.2 parts of defoaming agent, 0.12 parts of plasticizer, 1.3 parts of dodecyl alcohol ester film-forming aid, 0.1 part of leveling agent, and 0.12 part of anti-mold and fungicide.

[0032] Among them, the modified superfine hollow glass microspheres coated with titanium dioxide film are selected as the modified superfine hollow glass microspheres.

[0033] Among them, the elastic emulsion is a mixture of pure acrylic emulsion, silicone acrylic emulsion and water-based polyurethane emulsion, and its mass ratio is 3:1:2.

[0034] Wherein, the cellulose is selected from nano-cellulose crystals.

[0035] Among them, the antifoaming agent is composed of mineral oil in ...

Embodiment 2

[0040] A reflective heat-insulating coating, the composition of which is as follows in parts by mass: 24 parts of water, 12 parts of acrylic emulsion, 17 parts of surface-coated modified ultrafine hollow glass microspheres, 11 parts of rutile titanium dioxide, 10 parts of elastic emulsion, and 4 parts of cellulose , 0.2 parts of defoaming agent, 0.15 parts of plasticizer, 1.5 parts of dodecyl alcohol ester film-forming aid, 0.2 parts of leveling agent, and 0.15 parts of anti-mold and fungicide.

[0041]Among them, the modified superfine hollow glass microspheres coated with titanium dioxide film are selected as the modified superfine hollow glass microspheres.

[0042] Among them, the elastic emulsion is a mixture of pure acrylic emulsion, silicone acrylic emulsion and water-based polyurethane emulsion, and its mass ratio is 3.2:1:2.

[0043] Wherein, the cellulose is a mixture of nano-cellulose crystals and nitrocellulose, the mass ratio of which is 1:1.

[0044] Among them,...

Embodiment 3

[0049] A reflective heat-insulating coating, the composition of which is as follows in parts by mass: 25 parts of water, 15 parts of acrylic emulsion, 18 parts of surface-coated modified ultrafine hollow glass microspheres, 11 parts of rutile titanium dioxide, 11 parts of elastic emulsion, and 8 parts of cellulose , 0.3 parts of defoaming agent, 0.24 parts of plasticizer, 3.2 parts of dodecyl alcohol ester film-forming aid, 0.3 part of leveling agent, and 0.21 part of anti-mold fungicide.

[0050] Wherein, the surface-coated modified ultrafine hollow glass microspheres are coated with silicon dioxide / polytetrafluoroethylene composite film and modified ultrafine hollow glass microspheres.

[0051] Among them, the elastic emulsion is a mixture of pure acrylic emulsion, silicon acrylic emulsion and water-based polyurethane emulsion, and its mass ratio is 4:1:2.

[0052] Wherein, the cellulose is a mixture of nano-cellulose crystals and nitrocellulose, the mass ratio of which is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com