Fireproof cord fabric desk type sewing device

A sewing device, desktop technology, applied in the direction of cloth feeding mechanism, sewing equipment, sewing machine components, etc., can solve the problems of high labor intensity of workers, poor sewing effect, slow sewing speed, etc., and achieve good splicing effect and sewing speed. Faster and more efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

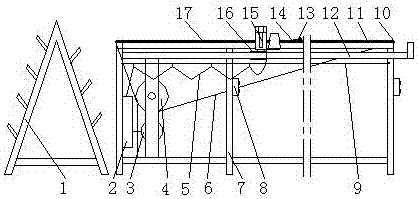

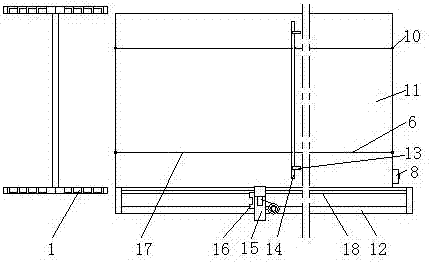

[0014] refer to figure 1 , figure 2 , a fireproof curtain desktop sewing device, a rectangular panel 11 is horizontally arranged on the surface of the frame 7, a traction bar 14 is horizontally provided on the panel 11, and two pulling bars 14 are connected to pull out Steel wire 6 and two pull back steel wire 17, be provided with control box 2, stepper motor 3, rotating shaft 4, switch box 8 under frame 7, pull out the other end of steel wire 6 through the pulley 10 that is located at panel 11 rear end Winding on the rotating shaft 4 from one direction, the other end of the pull-back steel wire 17 passes through the pulley 10 arranged at the front end of the panel 11 and then winding on the rotating shaft 4 from the other direction, the stepping motor 3 drives the rotating shaft 4 to rotate, on the side of the panel 11 The frame 7 of the frame 7 is fixedly provided with the sewing machine guide rail 12 parallel to the long side, and the sewing machine guide rail 12 is provi...

Embodiment 2

[0016] refer to figure 1 , figure 2 , a fireproof curtain desktop sewing device, a rectangular panel 11 is horizontally arranged on the surface of the frame 7, a traction bar 14 is horizontally provided on the panel 11, and two pulling bars 14 are connected to pull out Steel wire 6 and two pull back steel wire 17, be provided with control box 2, stepping motor 3, rotating shaft 4, switch box 8 under frame 7, pull out the other end of steel wire 6 through the pulley 10 that is located at panel 11 rear end Winding on the rotating shaft 4 from one direction, the other end of the pull-back steel wire 17 passes through the pulley 10 located at the front end of the panel 11 and then winding on the rotating shaft 4 from the other direction, the stepping motor 3 drives the rotating shaft 4 to rotate, on the side of the panel 11 The sewing machine guide rail 12 parallel to the long side is fixedly provided with on the frame 7 of the sewing machine, and a sliding sewing machine base 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com