Fully enclosed construction enclosure and arranging method thereof

A construction enclosure and fully enclosed technology, applied in the direction of fences, heating methods, lighting and heating equipment, etc., can solve problems such as unproposed solutions, achieve good lighting effects, obvious cooling effects, and significant cooling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

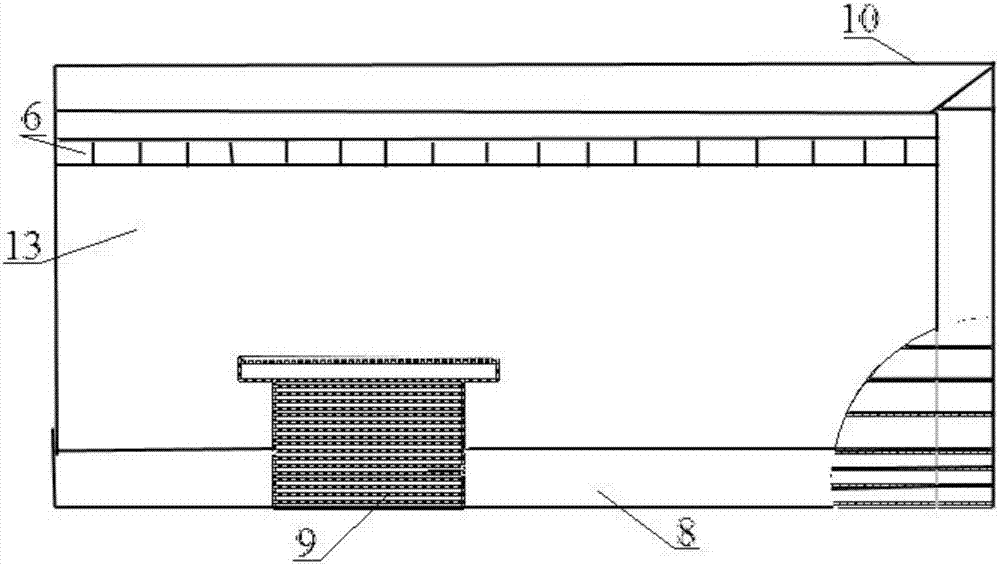

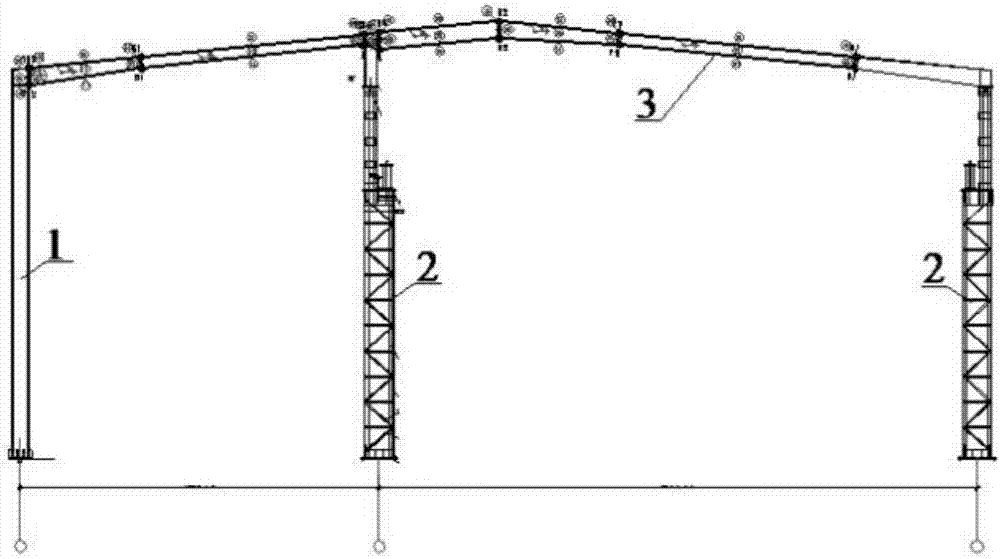

[0037] Embodiment 1: The structural structure of the fully enclosed construction enclosure

[0038] Such as Figure 1~5 As shown, the structural structure of a fully enclosed construction enclosure according to the embodiment of the present invention includes:

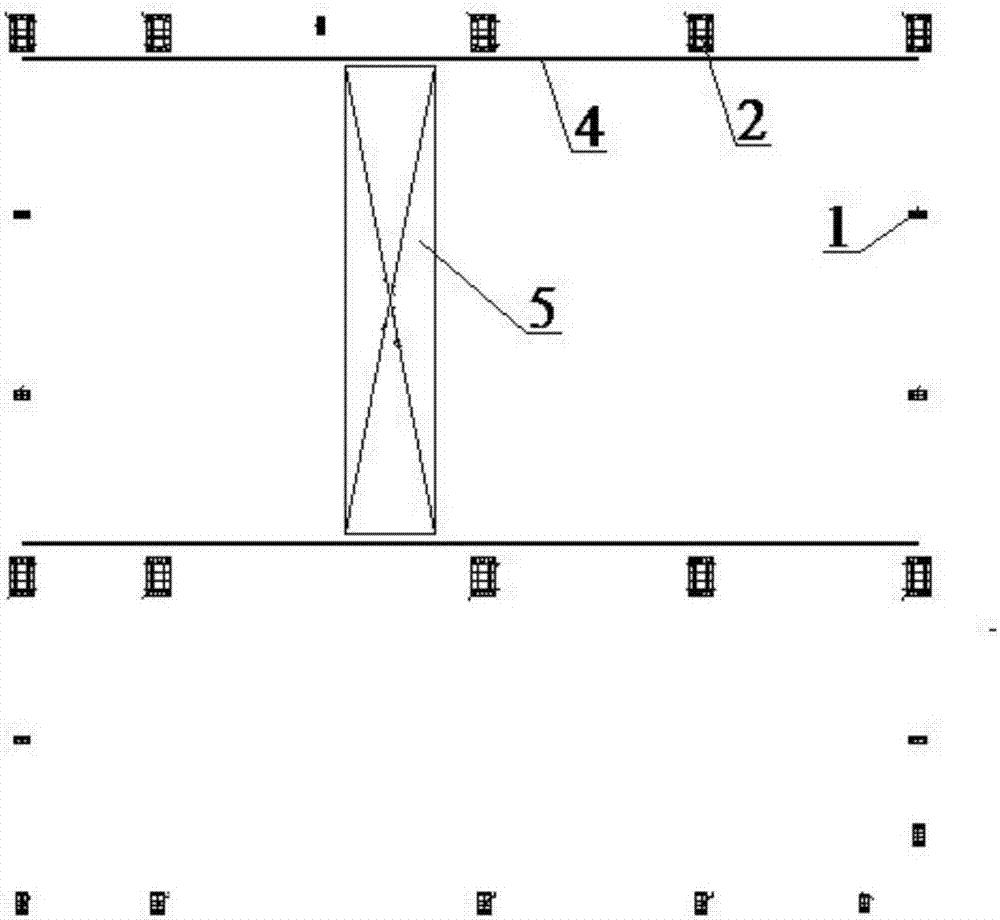

[0039] 1. Column and lattice column

[0040] A total of 23 columns and lattice columns are recorded in the fully enclosed construction area, such as figure 2 As shown, 10 of them are lattice columns, of which the upper 10 lattice columns and 5 columns are shared with the bridge lifting frame, and the remaining 8 are fully enclosed columns. Columns, lattice columns and foundation embedded bolts are connected by M36 high-strength bolts.

[0041] 2. Keel

[0042] The horizontal keel is made of 5×10cm galvanized square steel pipe, with a spacing of 1.2m / root (4 horizontal keels must be installed within 2m of the bottom to fix the steel plate-crystal plate composite structure), and the vertical keel is galvanized with a ...

Embodiment 2

[0050] Embodiment 2: Construction method of fully enclosed construction enclosure

[0051] 1. Steel structure engineering installation

[0052] That is, step S1. The specific steps are detailed as follows:

[0053] (1) Precautions before installation

[0054] ①Before the installation of structural components, a comprehensive inspection of the components should be carried out: whether the number, length, verticality, and bolt hole positions of the installation joints of the components meet the design requirements, and can be installed only after passing the test.

[0055] ② Steel columns can be installed only after the foundation has passed the acceptance check and the concrete strength has reached 75% of the design requirements, and the size of the anchor bolts has been checked and correct. Reasonable installation sequences and reliable safety measures should be adopted during installation to prevent permanent deformation of components , instability and safety accidents to ...

Embodiment 3

[0133] Example 3: Internal Settings

[0134] Soil silos are arranged adjacent to the vertical wellhead, and electromagnetic pulse dust collectors are arranged around the wellhead; sand and gravel silos are integrated with mixers to facilitate feeding and excavation. Soil silos and sand and gravel silos should be set near the entrance and exit; ideally, there should be a car wash Open space and slewing field; in other places, a two-story material stacking platform or processing platform is erected, and the lower floor is a personnel passage or warehouse. When used as a personnel passage, the second-story platform doubles as a protective shed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com