Centrifugal type carbon tank desorption device and method for exhaust gas turbine

An exhaust gas turbine and centrifugal technology, applied in the direction of exhaust device, muffler device, charging system, etc., to achieve the effect of short desorption time, reduce pollution and reduce cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

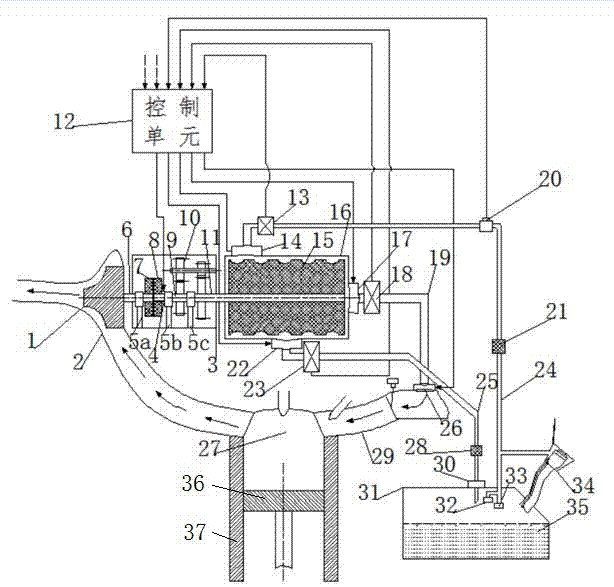

[0015] Such as figure 1 As shown, the automobile itself has an engine exhaust pipe 2 , a carbon canister 16 and a fuel tank 31 . A turbine 1 is placed in the middle of the engine exhaust pipe 2 inside of the automobile, and the center of the turbine 1 is collinear with the center of the engine exhaust pipe 2 . The turbine 1 is fixedly supported by the inner wall surface of the engine exhaust pipe 2 . The big end of the turbine 1 faces the direction of exhaust gas discharge, and the small end faces the direction of exhaust gas discharge.

[0016] There is a space between the turbine 1 and one end surface of the carbon canister 16 in the axial direction, and a clutch, a thrust device 4 and a speed reducer 10 are sequentially arranged in this space. Clutch is made up of clutch driving disc 7 and clutch driven disc 8, and speed reducer 10 is made up of the driving gear of speed reducer 10 and the output gear of speed reducer 10. The thrust device 4 is located between the clutch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com