Integrated type anti-freeze and pressure relief valve

A pressure relief valve, integrated technology, applied in the direction of safety valve, balance valve, valve device, etc., can solve the problems of unsatisfactory use effect, inability to work after power failure, reliability problems, etc., to achieve less parts and production. Low cost and the effect of avoiding pipeline icing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with accompanying drawing:

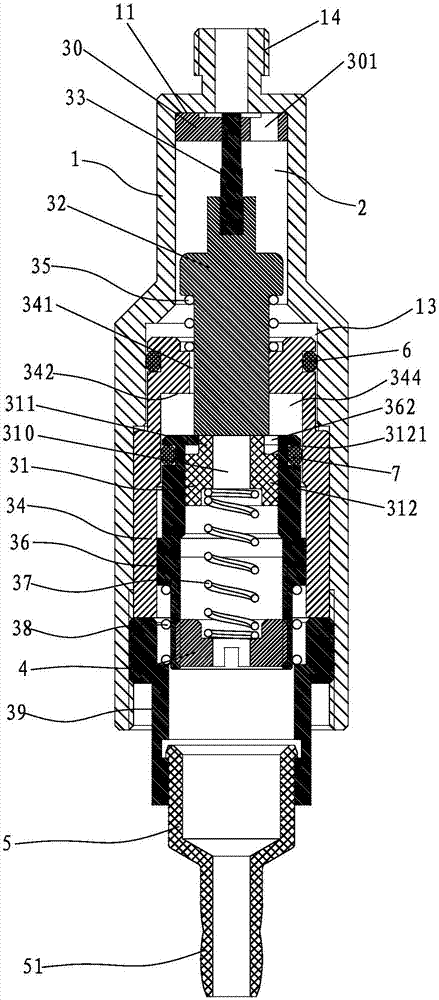

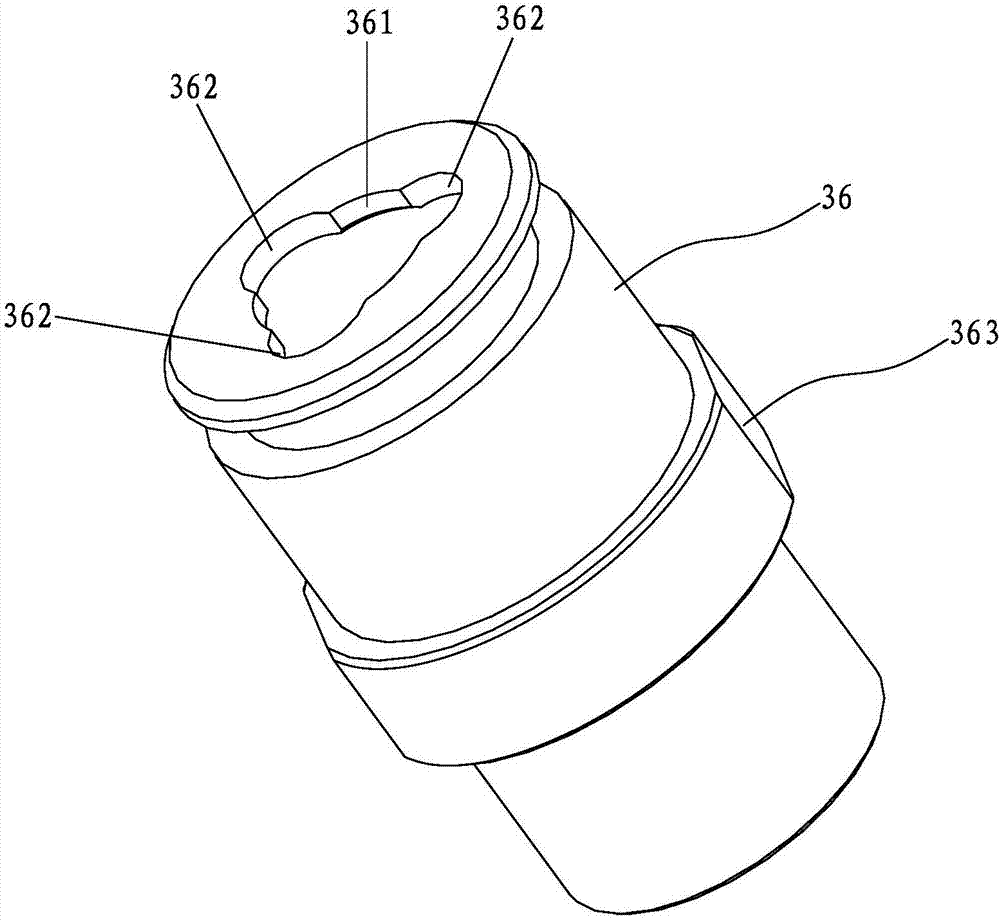

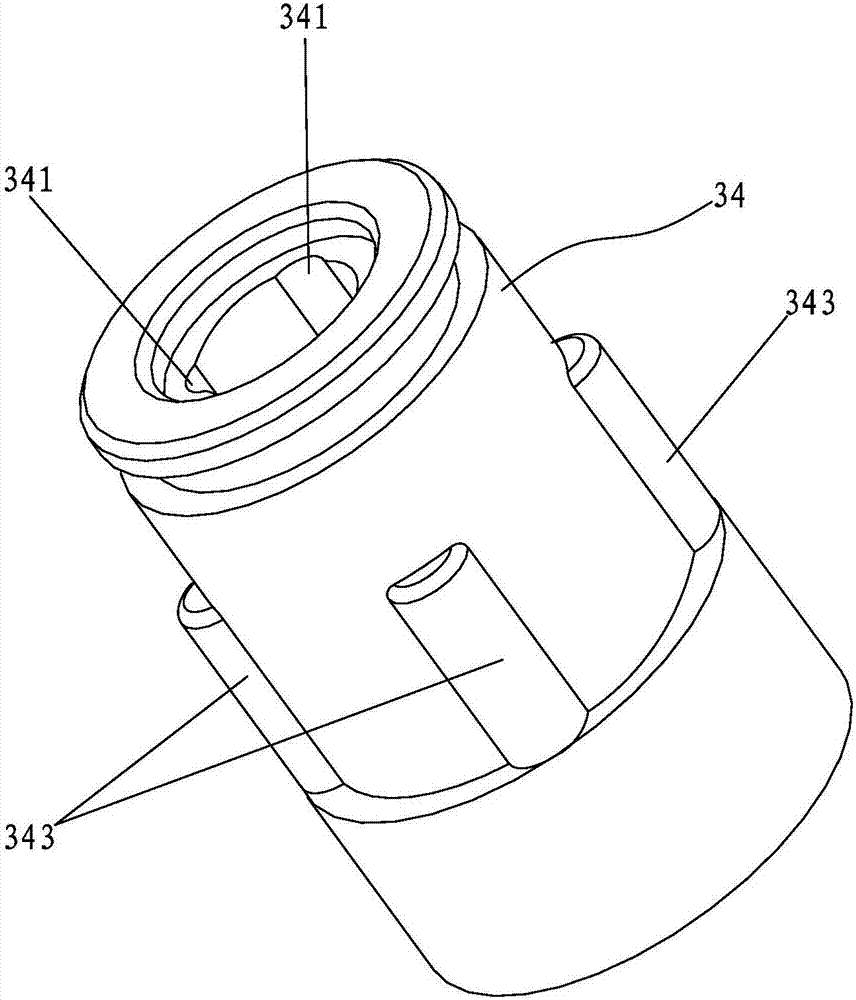

[0047] Such as Figure 1 to Figure 7The shown integrated antifreeze pressure relief valve includes a valve body 1, the valve body 1 is provided with a water channel 2 through which water flows, and the valve body 1 is provided with an antifreeze assembly capable of blocking the water channel 2, and When the ambient temperature is lower than the set temperature, the antifreeze component automatically opens the water channel 2 to drain water. Since the water temperature entering the house in winter in the north is not lower than 4°C, before the water heater water system is at the critical crystallization temperature, the integrated antifreeze The pressure relief valve keeps it in a flowing state. When the waterway absorbs enough heat energy carried by the flowing water and the frictional heat generated by the relative flow, the waterway system can always be above the critical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com