A rotary kiln turbulent combustion method

A combustion method and rotary kiln technology, applied in the fields of combustion and environmental protection, can solve problems such as difficult combustion, excessive slag ignition rate, and appearance of returned material at the rotary kiln head, so as to improve heat and mass transfer performance, improve combustion performance, Effect of improving combustion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

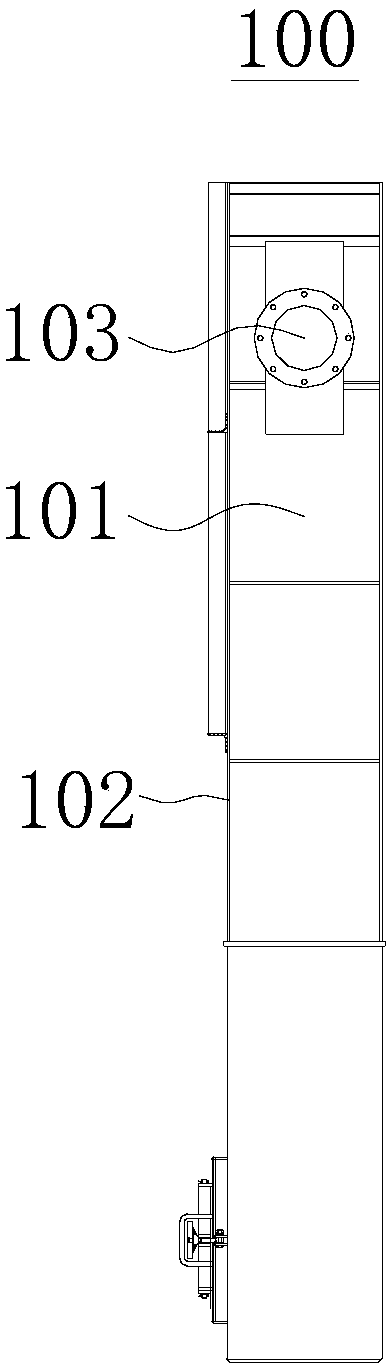

[0048] refer to figure 1 As shown, Embodiment 1 of the present invention provides a kiln head cover 100 , including a side wall 101 and an end cover 102 .

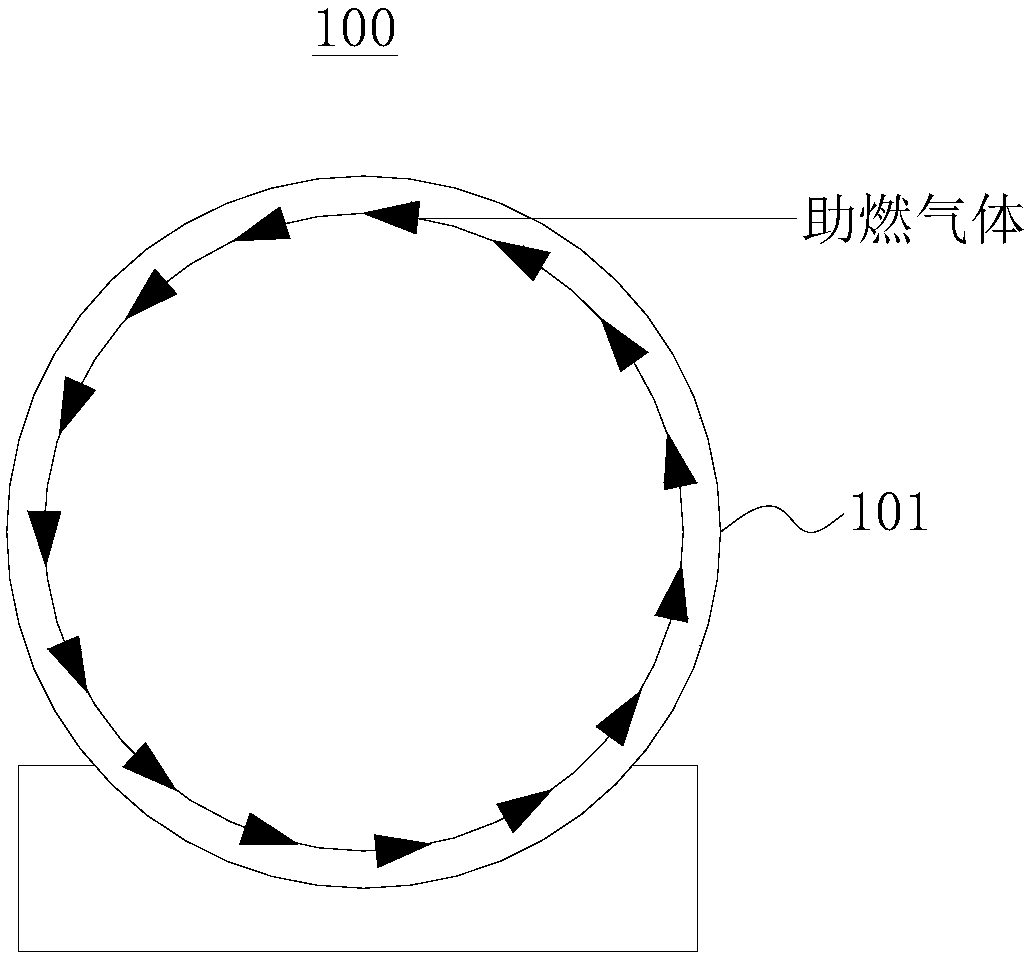

[0049] The side wall 101 and the end cover 102 enclose a receiving chamber with an open end, and the side wall 101 is provided with an air inlet 103 . Gas is passed into the kiln head cover 100 from the air inlet 103, and the movement direction of the gas is tangent to the inner surface of the side wall 101, and the gas can rotate in the kiln head cover 100 (such as figure 2 shown).

[0050] The side wall 101 can be rolled from a steel plate.

Embodiment approach 2

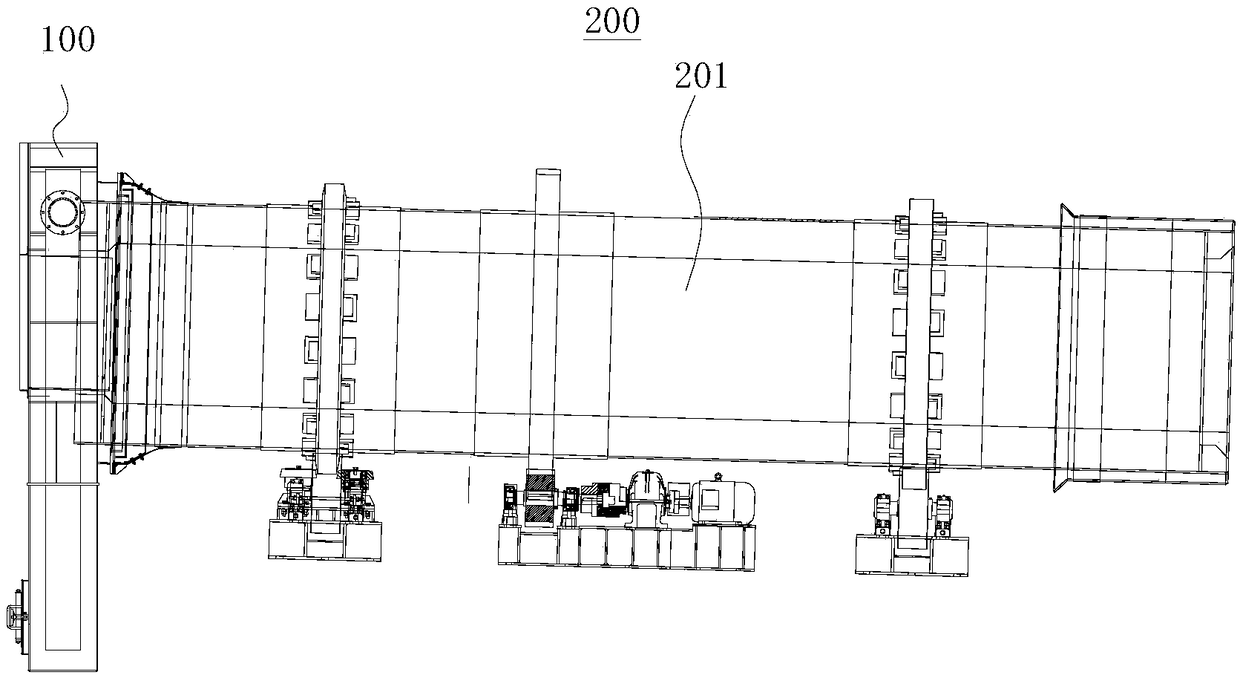

[0052] refer to image 3 As shown, Embodiment 2 of the present invention provides a rotary kiln 200 , including a cylinder body 201 and a kiln head cover 100 .

[0053] It should be noted that the kiln head cover 100 in this embodiment can adopt the kiln head cover 100 in the first embodiment, and its structure, working principle and technical effects can refer to the corresponding content in the first embodiment, which will not be described here. A detailed description.

[0054] The barrel 201 is a tubular structure with both ends open, and the interior of the barrel 201 is a combustion chamber. Materials can be incinerated in the combustion chamber.

[0055] The cylinder body 201 is formed by rolling and welding steel plates.

[0056] The kiln head cover 100 is arranged on one end of the cylinder body 201, the cylinder body 201 can rotate relative to the kiln head cover 100, a sealing device is arranged between the cylinder body 201 and the kiln head cover 100, and a circ...

Embodiment approach 3

[0061] Embodiment 3 of the present invention provides a combustion control method for a rotary kiln 200 , which is easy to operate and can fully burn waste.

[0062] It should be noted that the combustion control method of the rotary kiln 200 can be applied to the rotary kiln 200 in the second embodiment.

[0063] This rotary kiln 200 combustion control method comprises the following steps:

[0064] Heating step: before the operation of the rotary kiln 200, it is necessary to heat up the combustion chamber, ignite the burner of the rotary kiln 200, and gradually raise the temperature of the combustion chamber to between 650°C and 750°C according to the heating curve, preferably the temperature of the combustion chamber is raised to 700°C ℃ or so.

[0065] Ventilation step: When the temperature of the combustion chamber rises to the predetermined requirement, the combustion-supporting gas is introduced into the kiln head cover 100 from the air inlet 103 of the kiln head cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com