Aluminum alloy surface wire drawing quality detecting and evaluating method

A technology of aluminum alloy surface and evaluation method, which is applied in the direction of optical testing for flaws/defects, etc., to achieve the effect of simple and effective evaluation algorithm, improved clarity and detail resolution, and strong three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] A method for detecting and evaluating the quality of aluminum alloy surface drawing, comprising the following steps,

[0031] S1, produce working test pieces of standard size, after cleaning the surface of the working test pieces, extract test samples that meet the requirements, and label each test sample.

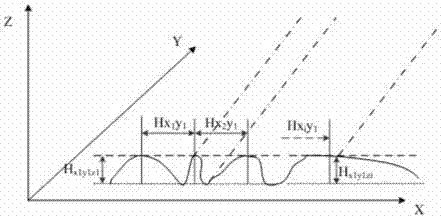

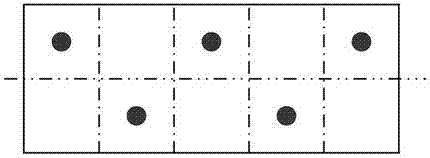

[0032] Before mass production, try to produce a "working sample", and the area of the working sample is not less than 5×1m 2 , the surface after wire drawing is blown on the working surface with high-pressure wind, clears the surface, drills samples with a certain distribution, and pays attention to the protective surface. location such as figure 1 As shown, the test sample area is not less than 20×20mm 2 , the total number of testing samples is not less than 5. It should be noted that the number of testing samples can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com