Multi-effect Compound Fertilizer System Based on Internet Monitoring and Intelligent Control of Straw Fermentation

A compound fertilizer and straw technology, applied in the Internet field, can solve the problems of lack of supporting technology and equipment, high operating costs, no effective market mechanism and storage and transportation system, etc., to facilitate commercial development, improve multi-function, and realize quick-acting and slow-moving Interpret the effect of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

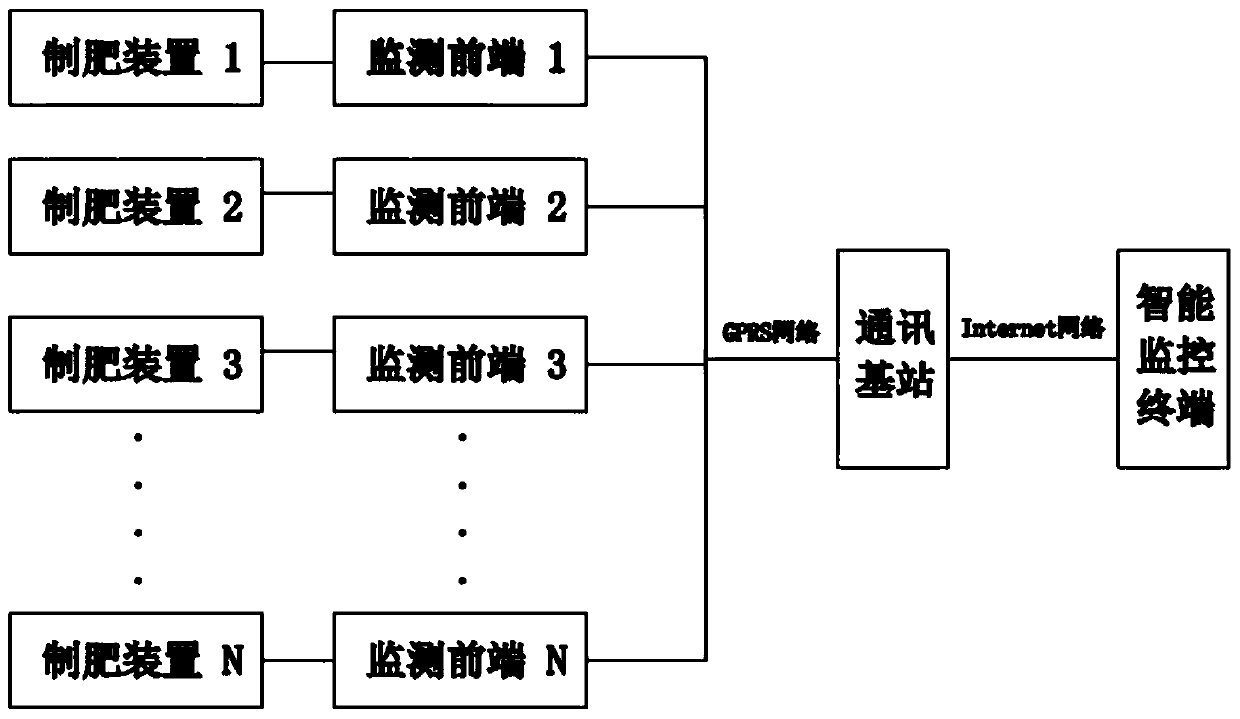

[0039] like figure 1 As shown in the figure, an intelligent control straw fermentation system for preparing multi-effect compound fertilizer based on Internet monitoring includes a fertilizer making device installed at each straw processing point, a monitoring front end installed on the fertilizer making device, a communication base station, and an intelligent monitoring terminal. The monitoring front end communicates with the communication base station through the GPRS network, and the communication base station communicates with the intelligent monitoring terminal through the Internet network, and the monitoring front end realizes monitoring, collecting and transmitting the operating data in the fertilizer making device; such as fermentation in the fertilizer making device Temperature, humidity, nutrient addition status of fermentation broth, fermentation quality and time, the monitoring front end transmits the monitored real-time parameters of the fertilizer making device to...

Embodiment 2

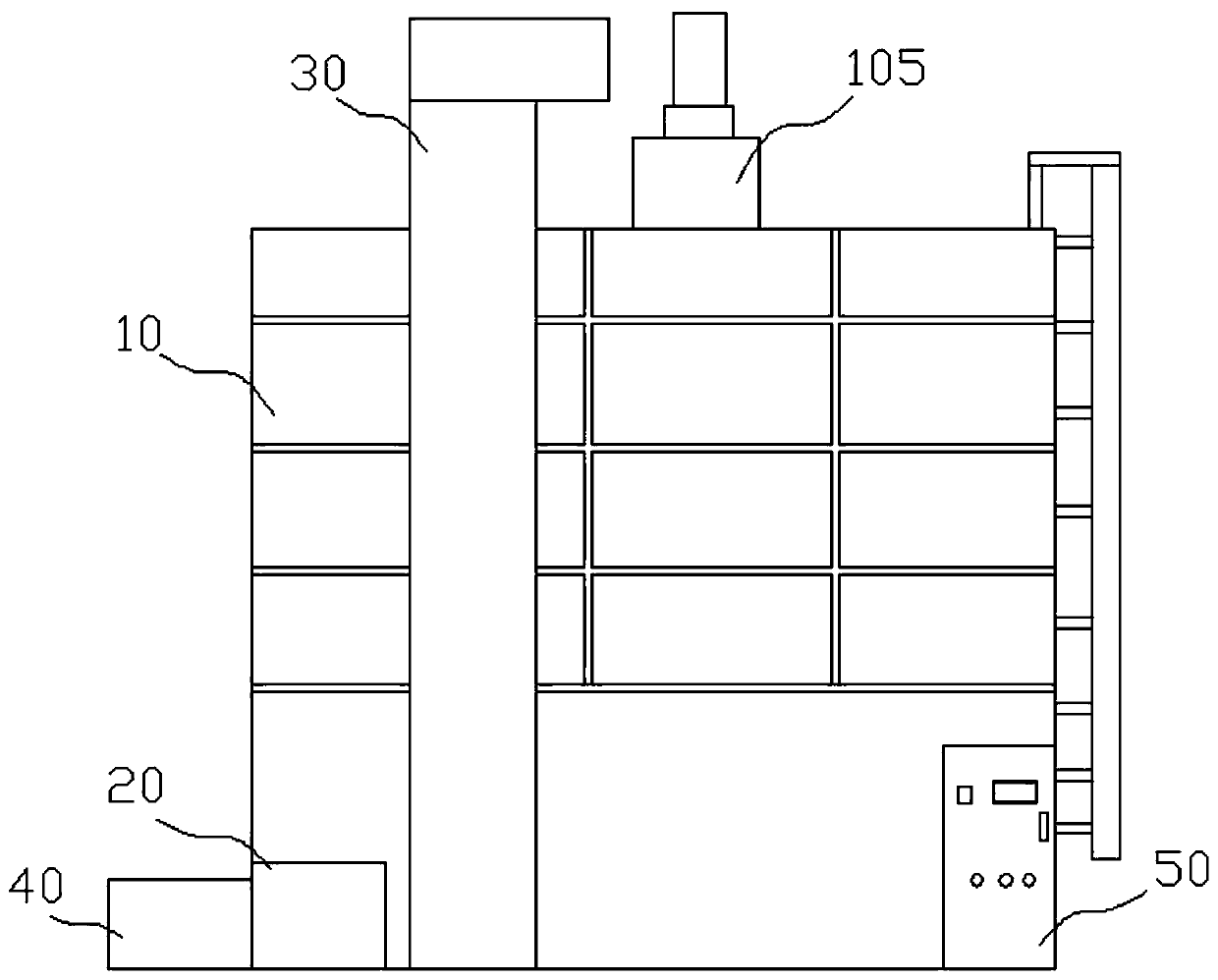

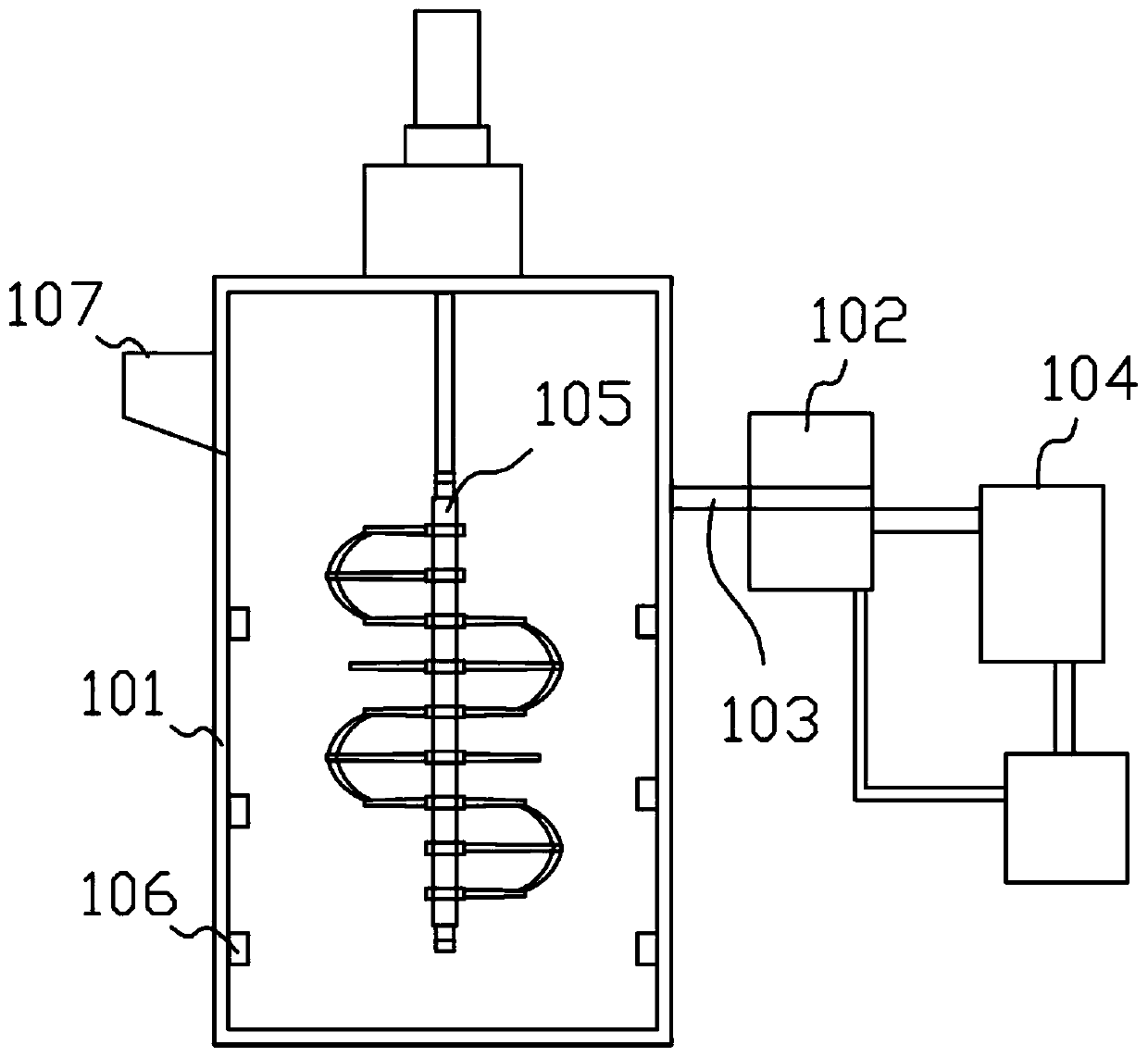

[0041] like figure 2 , image 3 As shown, a device for preparing multi-effect compound fertilizer by intelligently controlling straw fermentation includes: double-tower fermenter 10, crushing mechanism 20, automatic feeding mechanism 30, automatic discharging mechanism 40, monitoring front end 50, communication base station and intelligent monitoring terminal The monitoring front end 50 is arranged on the double-tower fermentation tank 10, the monitoring front end 50 communicates with the communication base station through the GPRS network, and the communication base station communicates with the intelligent monitoring terminal through the Internet network, and the monitoring front end realizes the monitoring of the operation data in the fertilizer making device, Collection and transmission; such as the fermentation temperature, humidity, nutrient addition status of the fermented liquid, fermentation quality and time in the fertilizer making device, the monitoring front end t...

Embodiment 3

[0056] A process for developing multifunctional fertilizers with high value of straw, the steps are:

[0057] (1) Feed the crop stalks into the crushing mechanism for crushing, such as wheat stalks and corn stalks, and carry out crushing according to different specifications of different stalks, generally according to the length not longer than 5cm, to obtain straw debris;

[0058] (2) Spray the fermenting agent on the crushed straw debris, stir and mix them, and then input them into the double-tower fermentation tank through the automatic feeding mechanism to seal them for anaerobic fermentation and decomposing, and use the fermentation heat to naturally inactivate, sterilize and kill pests; The physical properties, chemical properties and mechanical properties are different, and the fermentation temperature and time are also different. Generally, it is ensured that the temperature in the double-tower fermentation tank is not higher than 55°C, and the time is 4-10 days; and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com