Water-filled multi-layer box structure of the shielded workshop of the third generation nuclear power plant

A box structure and shielding plant technology, which is applied in nuclear power plant auxiliary equipment, shielding, nuclear power generation, etc., can solve the problems of huge construction costs and restrictions on the development of nuclear power, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

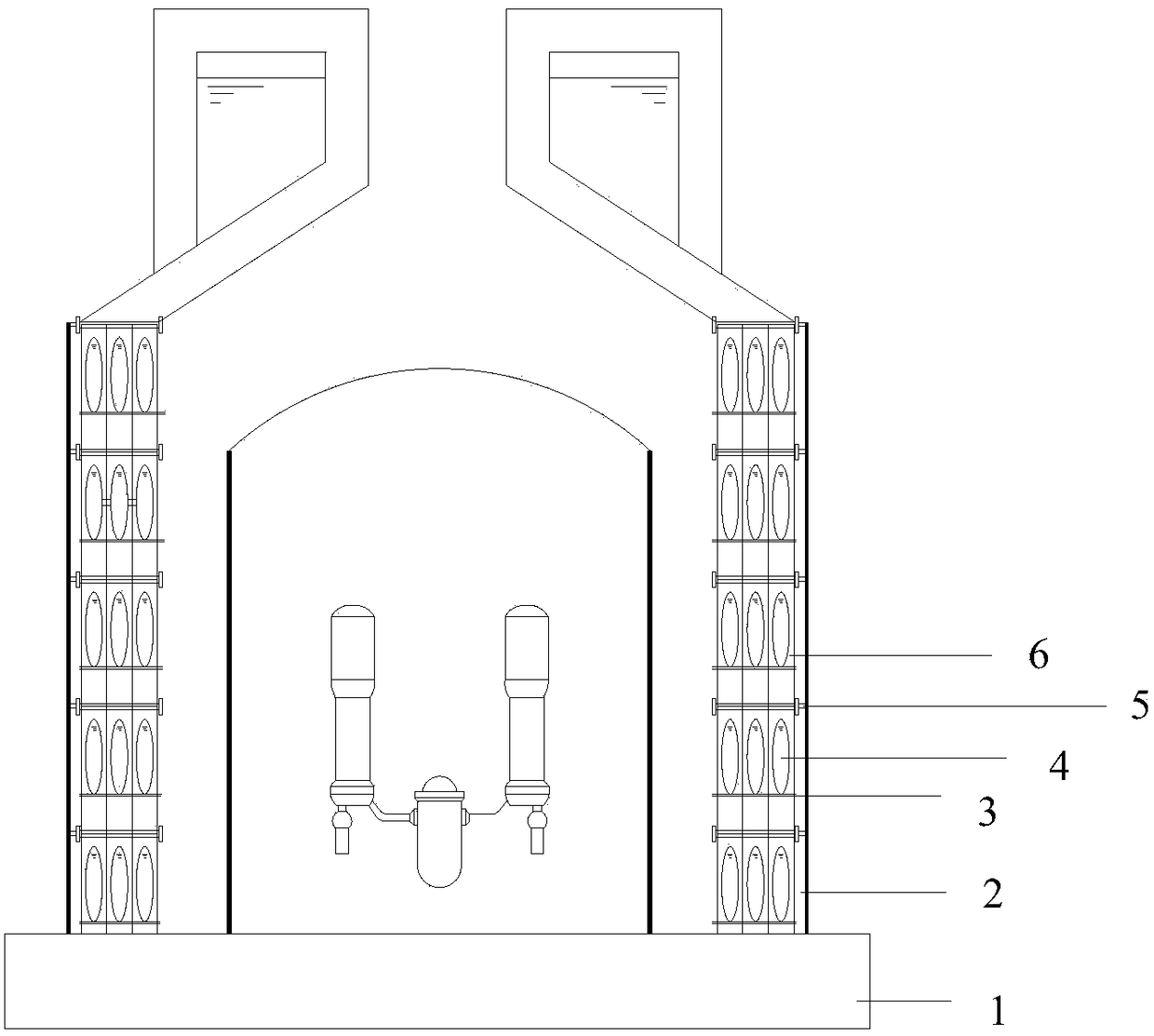

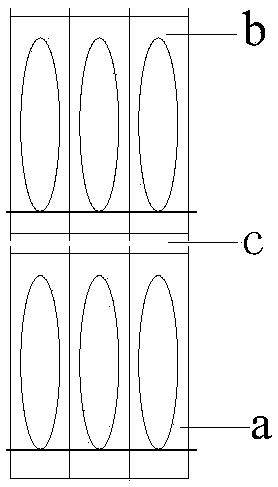

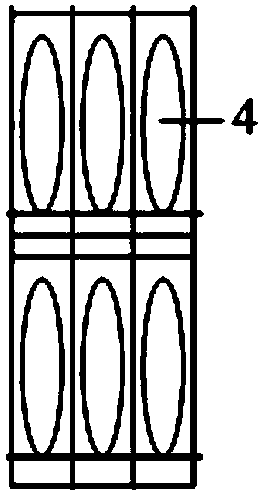

[0016] The invention proposes and realizes a new type of water-filled multi-box structure for the third-generation nuclear power plant shielding plant, changes the structural form of the traditional prestressed reinforced concrete cylinder shielding plant, and realizes the modular installation of the water-filled multi-layer box shielding plant structure. The cavity of the multi-layer box is filled with high-pressure water added with radioactive absorbent, which serves as a safety reserve in case of an accident, which improves the safety and stability of the structure, and at the same time reduces the radioactivity released by the nuclear island reactor to the environment. The multi-layer box is welded or bolted by section steel, and micro-expansion high-strength concrete is injected into the cavity. The applied externally prestresse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com