Pole tab smoothing follow-up mechanism and lithium battery winding machine

A follow-up mechanism and pole ear technology, which is used in battery assembly, secondary battery manufacturing, non-aqueous electrolyte storage battery, etc. Simple and practical, good smoothing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific drawings.

[0026] In the description of the following specific embodiments, the coordinates are all adopted: with figure 1 The direction in which the vertical paper faces outward is the front, and the opposite direction is the back.

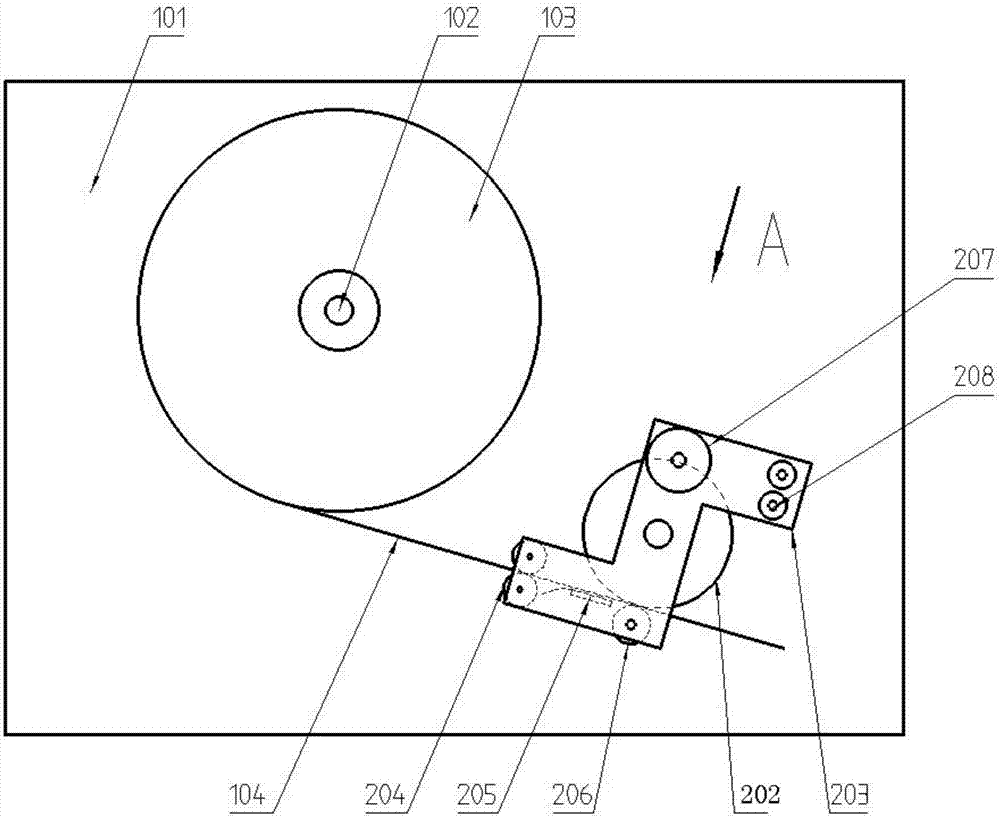

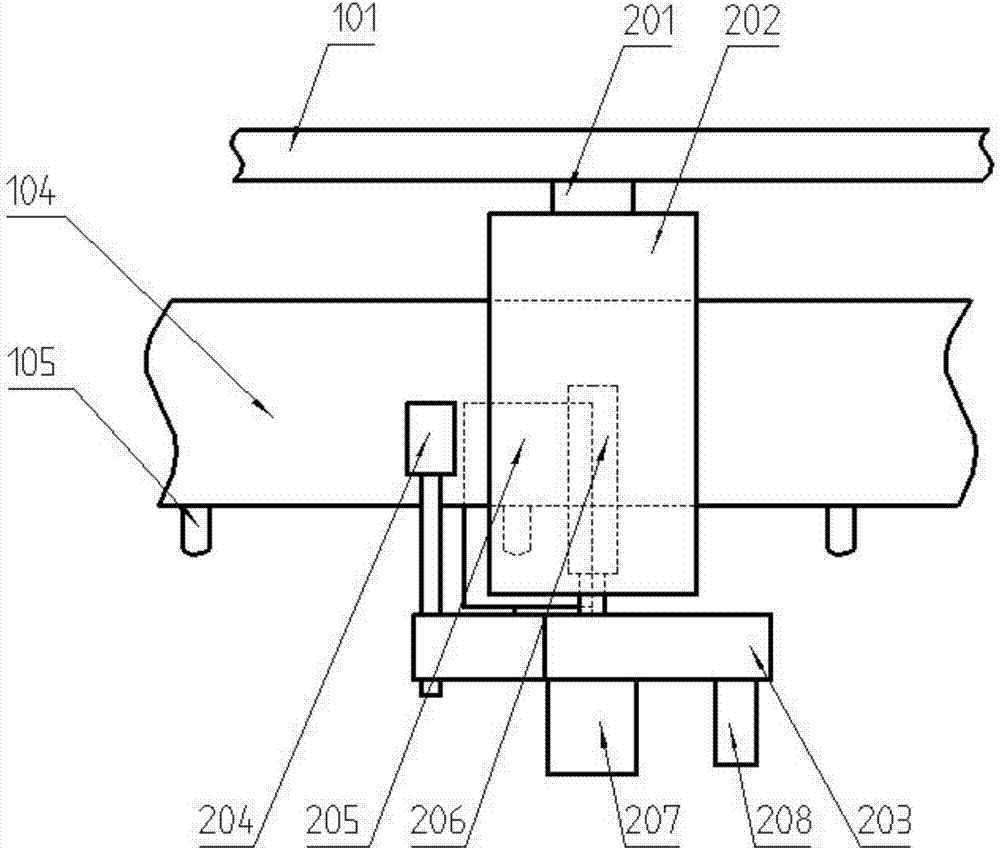

[0027] Such as figure 1 As shown, the lug smoothing follow-up mechanism of the present invention includes a frame plate 101, on which a material reel 102 is rotated and installed, and a material reel 103 is worn on the material reel 102, and the material reel 103 releases the material with the lug 105. pole piece 104 . On the frame plate 101 on the right lower side of the material reel 102, the roller shaft 201 is rotated, and the driving roller 202 and the balance plate 203 are installed on the roller shaft 201. The balance plate 203 is in an inverted Z shape, and the rear of the balance plate 203 Two parallel guide rollers 204 are installed on the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com