Resistance increasing body and heading machine

A technology of blocking body and driver, which is applied in mining equipment, tunnels, earth-moving drilling and other directions, can solve the problems of unsuitable and limited use range of the roadheader, and achieve the effect of wide range of use and stable working performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

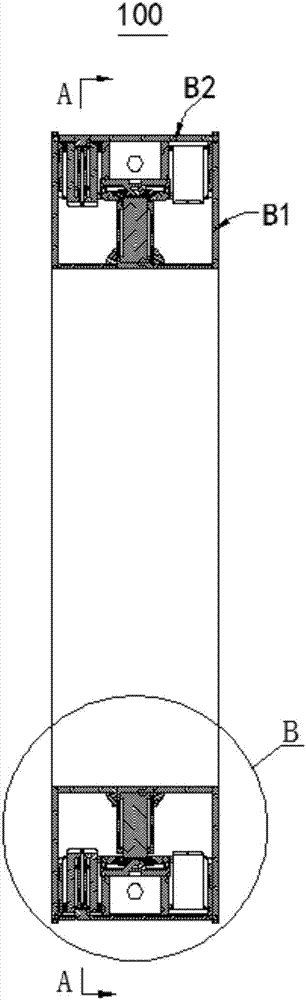

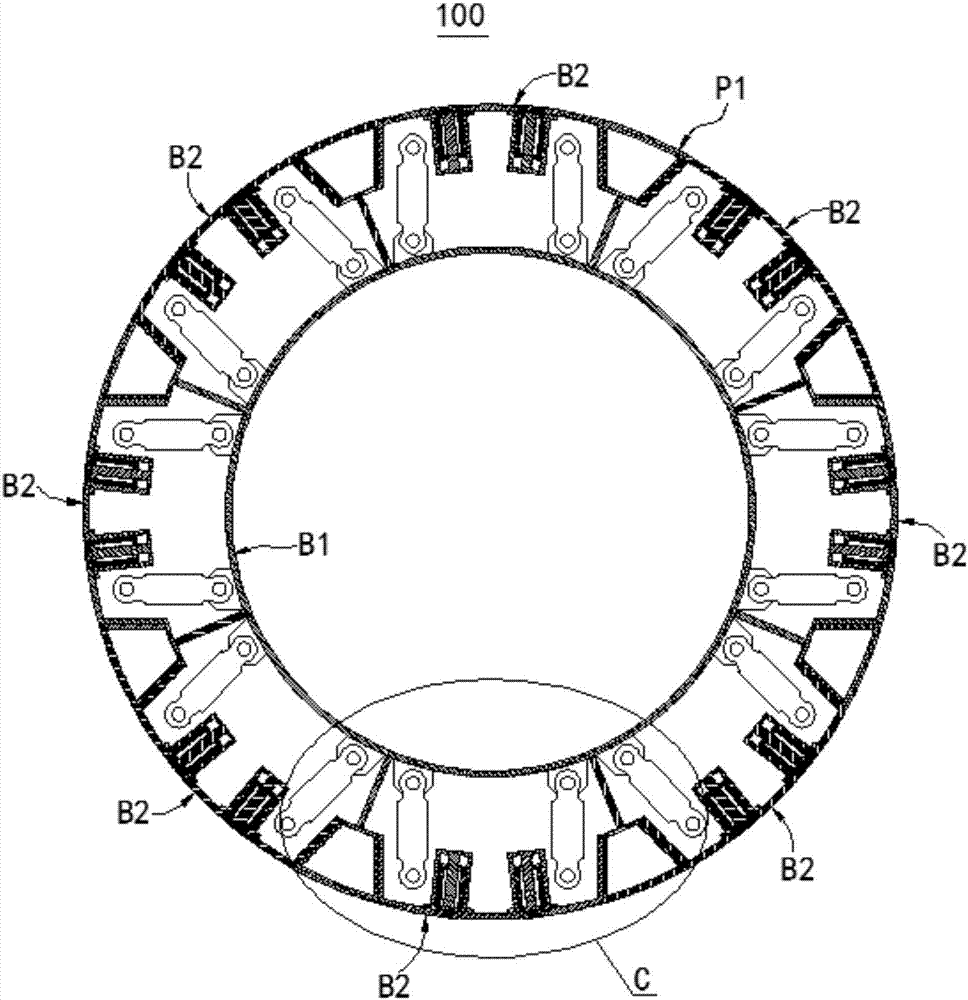

[0047] figure 1 It is a schematic diagram of the structure of the resistance increasing body 100 in the first embodiment of the present invention, and is shown in a cross-sectional view; figure 2 Yes figure 1 A cross-sectional view along the line A-A, the two figures together show the structure of the resistance increasing body 100 in this embodiment. Please refer to figure 1 , figure 2 The resistance increasing body 100 in this embodiment includes an annular support frame B1 and a plurality of resistance increasing mechanisms B2 distributed along the circumferential direction of the support frame B1. The outer surface of the support frame B1 is defined as the outer ring surface P1.

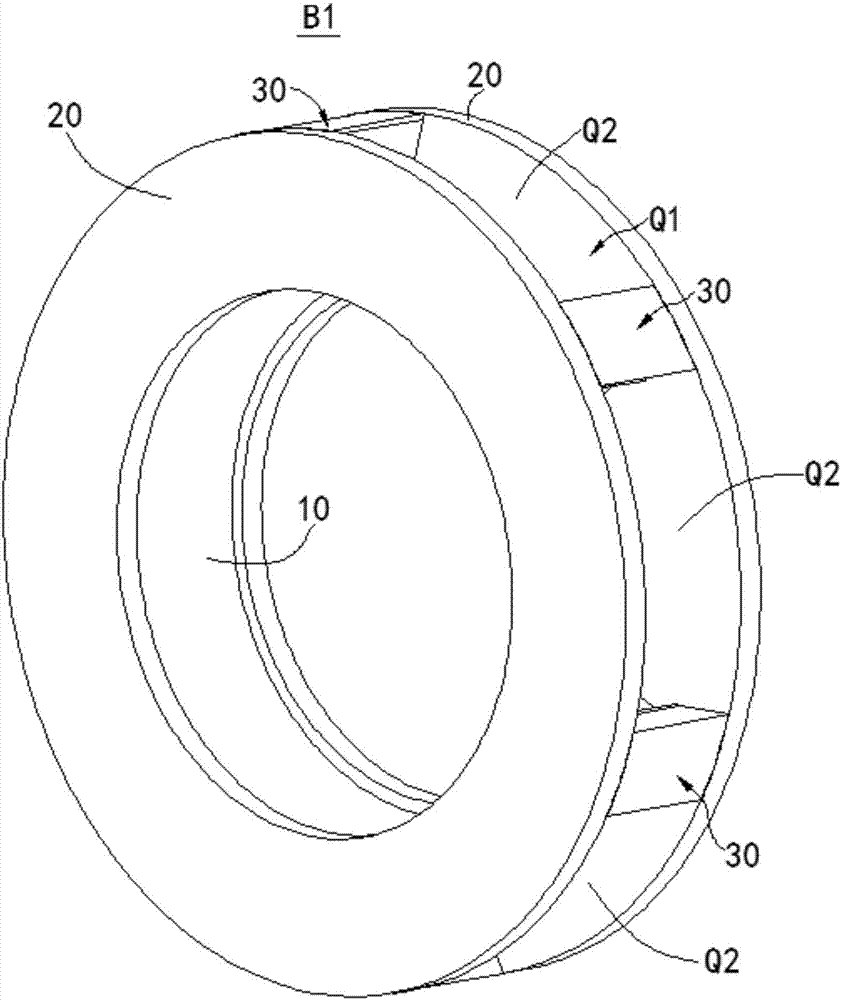

[0048] image 3 Yes figure 1 A perspective view of support frame B1 in. Please refer to image 3 The support frame B1 includes a cylindrical inner wall 10 and two annular end walls 20 respectively connected to the axial ends of the inner wall 10. The inner wall 10 and the two end walls 20 jointly...

Embodiment 2

[0058] Picture 12 It is a schematic diagram of the structure of the roadheader 010 in the embodiment of the present invention. See Picture 12 The roadheader 010 in this embodiment includes a cutter head 200 and a plurality of resistance increasing components 100a arranged at intervals along the axial direction. Adjacent drag-increasing components 100a are drivingly connected by an axial thruster 300. The cutter head 200 is connected to the outer end of the resistance increasing assembly 100a at the axial outer end. Optionally, there are two resistance increasing components 100a. The two resistance-increasing components 100a are connected to each other through an axial thruster 300, and the outer end of one of the resistance-increasing components 100a is connected to the cutter head 200 through an axial thruster 300. Each resistance increasing component 100a includes two resistance increasing bodies 100 connected along the axial direction. In other embodiments, the cutter h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com