naxmno2 positive electrode material, preparation method and application

A positive electrode material and thermal reaction technology, applied in the field of electrochemical energy storage, can solve the problems of narrow potential window and low energy density, and achieve the effect of good bendable and foldable type, short preparation process and convenient mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The first step: pretreatment of carbon cloth: treat the carbon cloth with nitric acid at 90°C for 6 hours to remove surface impurities, and store it in absolute ethanol for later use.

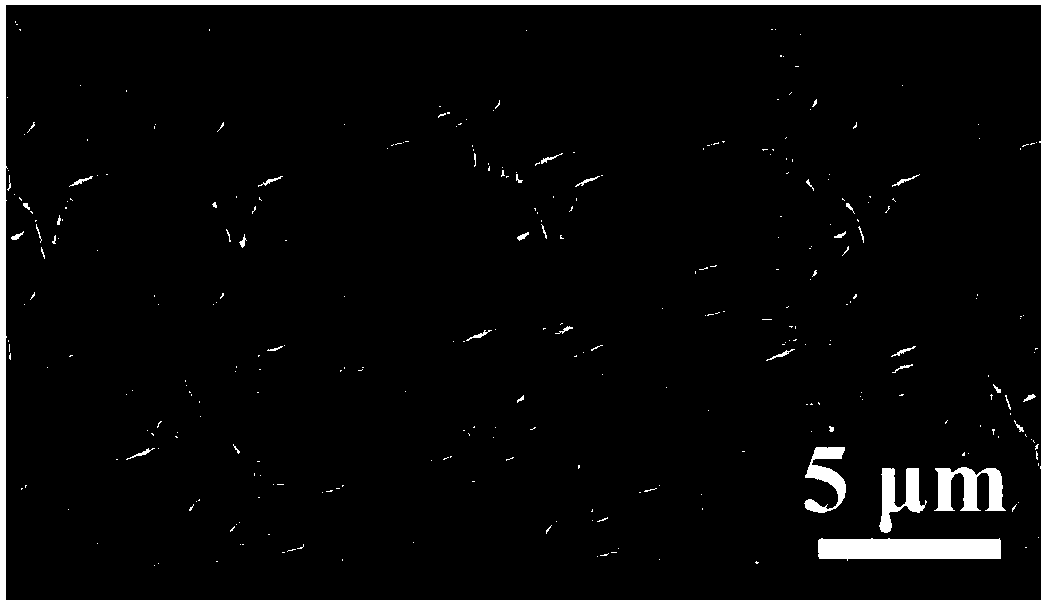

[0023] Step 2: Preparation of Mn on carbon cloth by cathodic electrodeposition 3 o 4 Nanowall arrays. The cathodic electrodeposition method is based on a three-electrode system, in which carbon cloth is used as the working electrode, platinum sheet is used as the counter electrode, and Ag / AgCl is used as the reference electrode. Perform constant voltage deposition at -1.8V in the middle, keep it for 20min, and get Mn(OH) 2 array of nanowalls, then placed in air to eventually form Mn 3 o 4 Nanowall arrays.

[0024] Step Three: At Mn 3 o 4 On the basis of nanowall arrays, a hydrothermal method was used to prepare Na 0.55 MnO 2 Nanowall arrays. Specifically include: the Mn 3 o 4 The nanowall array was submerged in 40 mL of 1M NaOH solution, and then transferred to a hydrothermal...

Embodiment 2

[0027] The first step: pretreatment of carbon cloth: treat the carbon cloth with nitric acid at 90°C for 6 hours to remove surface impurities, and store it in absolute ethanol for later use.

[0028] Step 2: Preparation of Mn on carbon cloth by cathodic electrodeposition 3 o 4 Nanowall arrays. The cathodic electrodeposition method is based on a three-electrode system, in which carbon cloth is used as the working electrode, platinum sheet is used as the counter electrode, and Ag / AgCl is used as the reference electrode. Perform constant voltage deposition at -1.8V in the middle, keep it for 20min, and get Mn(OH) 2 array of nanowalls, then placed in air to eventually form Mn 3 o 4 Nanowall arrays.

[0029] Step Three: At Mn 3 o4 On the basis of nanowall arrays, a hydrothermal method was used to prepare Na 0.55 MnO 2 Nanowall arrays. Specifically include: the Mn 3 o 4 The nanowall array was submerged in 40 mL of 1M NaOH solution, and then transferred to a hydrothermal k...

Embodiment 3

[0032] The first step: pretreatment of carbon cloth: treat the carbon cloth with nitric acid at 90°C for 6 hours to remove surface impurities, and store it in absolute ethanol for later use.

[0033] Step 2: Preparation of Mn on carbon cloth by cathodic electrodeposition 3 o 4 Nanowall arrays. The cathodic electrodeposition method is based on a three-electrode system, in which carbon cloth is used as the working electrode, platinum sheet is used as the counter electrode, and Ag / AgCl is used as the reference electrode. Perform constant voltage deposition at -1.8V in the middle, keep it for 20min, and get Mn(OH) 2 array of nanowalls, then placed in air to eventually form Mn 3 o 4 Nanowall arrays.

[0034] Step Three: At Mn 3 o 4 On the basis of nanowall arrays, a hydrothermal method was used to prepare Na 0.55 MnO 2 Nanowall arrays. Specifically include: the Mn 3 o 4 The nanowall array was immersed in 40mL of 1M-NaOH solution, and then transferred to a hydrothermal k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com