Method for preparing NaxMnO2 electrode materials in large scale

An electrode material and a large-scale technology, applied in the field of electrochemical energy storage, can solve the problems of difficult electrode material preparation, difficult large-scale preparation, complex process, etc., and achieve excellent electrochemical performance, easy large-scale industrial production, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

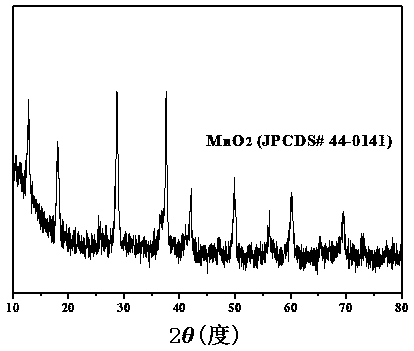

[0023] a) 9 g MnSO 4 Dissolve in 80 mL deionized water as solution A; 6 g KMnO 4 Dissolve in 200 mL to form solution B; slowly add solution A to solution B, place in a reaction kettle, react at 140°C for 12 hours, cool to room temperature, wash with deionized water, and dry. Then calcined in air at 400°C for 2 hours to obtain MnO 2 .

[0024] b) the MnO obtained in step a) 2 with anhydrous NaNO 3 Mix at a mass ratio of 2:1, and put the ball ink in a ball mill for 24 hours.

[0025] c) Put the mixture obtained in step b) into a muffle furnace, calcinate in air at 870°C for 12 hours, then wash with deionized water and dry to obtain NaxMnO 2 .

Embodiment 2

[0027] a) 9 g MnSO 4 Dissolve in 80 mL deionized water as solution A; 6 g KMnO 4 Dissolve in 200 mL to form solution B; slowly add solution A to solution B, place in a reaction kettle, react at 140°C for 12 hours, cool to room temperature, wash with deionized water, and dry. Then calcined in air at 400°C for 2 hours to obtain MnO 2 .

[0028] b) the MnO obtained in step a) 2 with anhydrous NaNO 3 Mix at a mass ratio of 1:1, and put the ball ink in a ball mill for 24 hours.

[0029] c) Put the mixture obtained in step b) into a muffle furnace, calcinate in air at 870°C for 12 hours, then wash with deionized water and dry to obtain NaxMnO 2 .

Embodiment 3

[0031] a) 9 g MnSO 4 Dissolve in 80 mL deionized water as solution A; 6 g KMnO 4 Dissolve in 200 mL to form solution B; slowly add solution A to solution B, place in a reaction kettle, react at 140°C for 12 hours, cool to room temperature, wash with deionized water, and dry. Then calcined in air at 400°C for 2 hours to obtain MnO 2 .

[0032] b) the MnO obtained in step a) 2 with anhydrous NaNO 3 Mix at a mass ratio of 1:2, and put the ball ink in a ball mill for 24 hours.

[0033] c) Put the mixture obtained in step b) into a muffle furnace, calcinate in air at 870°C for 12 hours, then wash with deionized water and dry to obtain NaxMnO 2 .

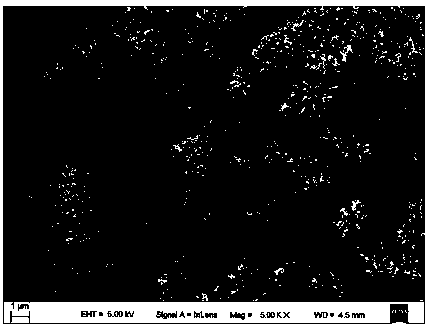

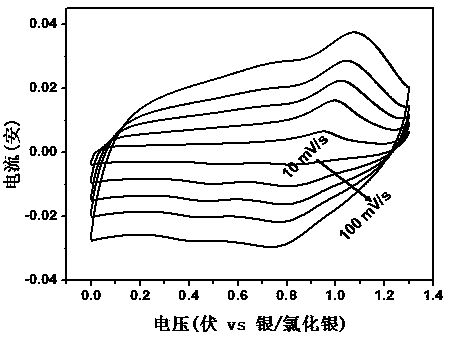

[0034] The preparation method of the invention has simple process, low requirements on equipment, has practicability, and is easy for large-scale industrial production. Prepared NaxMnO 2 With high specific capacitance and wide voltage window, electrode materials with special morphology and certain particle size and distribution ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com