Automatic emulsion preparation apparatus

A technology for automatic liquid dispensing and emulsification, which is used in mixer accessories, transportation and packaging, chemical instruments and methods, etc. It can solve the problems of wear, corrosion, and need to be improved of underground hydraulic equipment, so as to prevent wear and corrosion and improve liquid dispensing. Efficiency, the effect of improving the quality of liquid supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

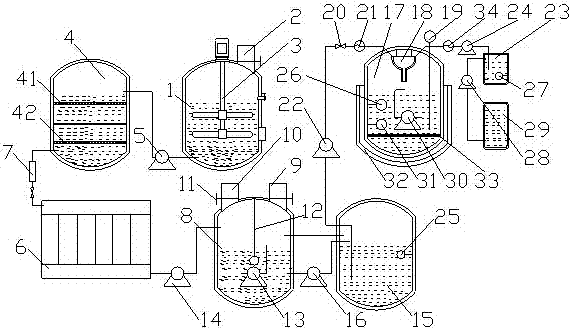

[0019] Such as figure 1 As shown, a kind of emulsion automatic dispensing device proposed by the present invention includes: a water purification device, a liquid dispensing device and a controller;

[0020] The water purification device includes a flocculation pretreatment device 1, a filter device 4, a water softening device 6, a pH adjustment device 8 and a water storage device 15; the flocculation pretreatment device 1 has a mine water inlet, and a flocculant tank 2 and a stirring mechanism are arranged on it 3. The flocculation pretreatment device 1, the filter device 4, the water softener 6, the pH adjustment device 8 and the water storage device 15 are sequentially connected through pipelines; the filter device 4 is provided with at least two layers of high-efficiency filter screens, and the high-efficiency filter screens include The upper quartz sand filter screen 41 and the activated carbon filter screen 42 located at the lower part, the first clean water pump 5 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com