Tool magazine structure of direct-drive type servo motor controlled cutter disc

A servo motor and direct drive technology, which is applied in the field of the tool magazine structure of the direct drive servo motor to control the cutter head, can solve the problems of high operating noise, high wear rate, high cost of use, and complex structure, so as to improve the operating speed, Effects of reducing wear and noise and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

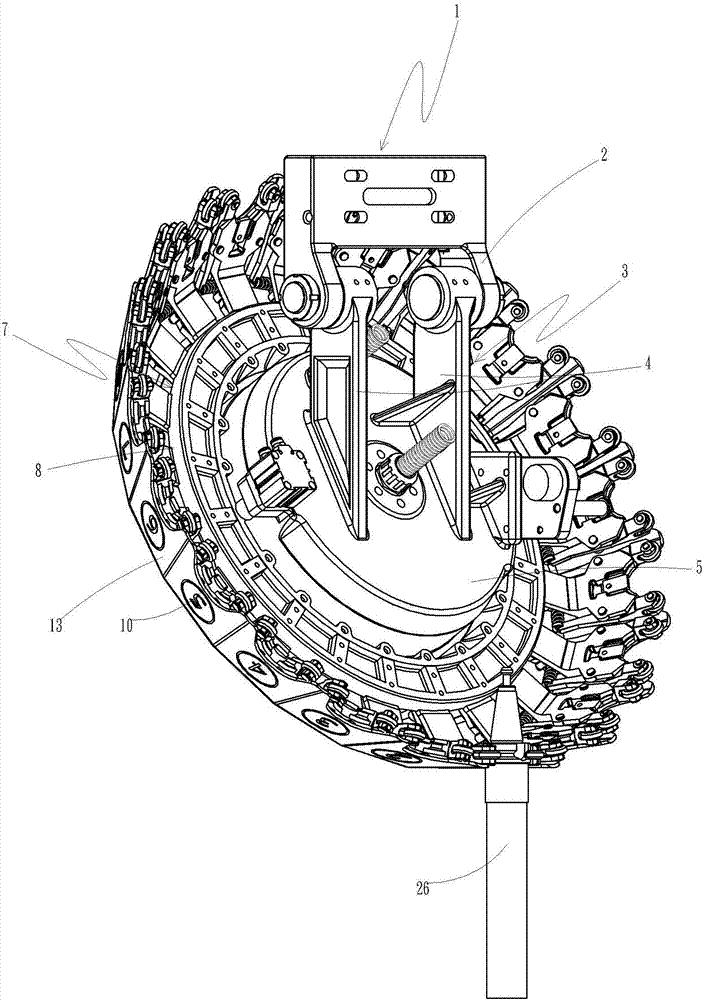

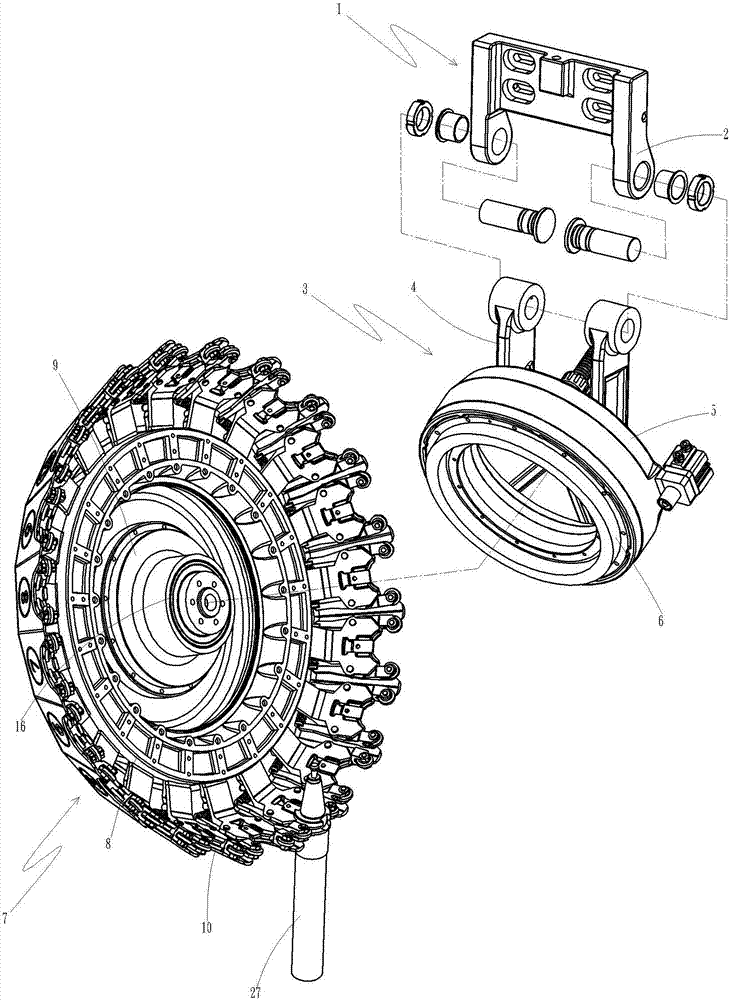

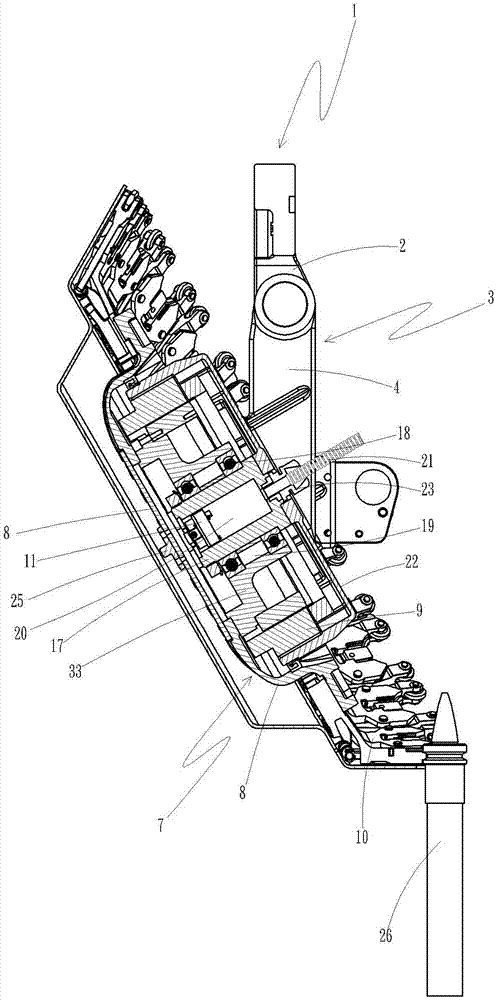

[0025] Direct drive servo motor controls the tool magazine structure of the cutter head, which is installed in a machine tool, see Figure 1 to Figure 5 , which includes:

[0026] A fixed seat 1, two pivot ears 2 are arranged on one side of the fixed seat 1, and the fixed seat 1 is combined with the machine tool;

[0027] A cutter head body 3, the cutter head body 3 is provided with a pivot arm 4, one end of the pivot arm 4 is fixed with a cutter head seat 5, and the cutter head seat 5 is provided with a direct drive servo motor 6, the pivot arm 4 Correspondingly pivotally combined with the pivot ear 2 of the fixed seat 1;

[0028] And a cutterhead group 7, the cutterhead group 7 is provided with a cutterhead 8, the rear side of the center position of the cutterhead 8 is fixed with a cutterhead mounting seat 9, and the peripheral ring of the cutterhead 8 is provided with some knife claws Group 10, each claw group 10 is respectively arranged with a cutter 26, the cutter head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com