Polishing solution online mixing and internal supply polishing machine tool

A polishing liquid and machine tool technology, which is applied in the direction of grinding machine tools, grinding/polishing equipment, gas/liquid distribution and storage, etc., can solve the problem that the components of the polishing liquid cannot be kept stable, achieve timely and fixed-point delivery, and ensure chemical stability performance, improving stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

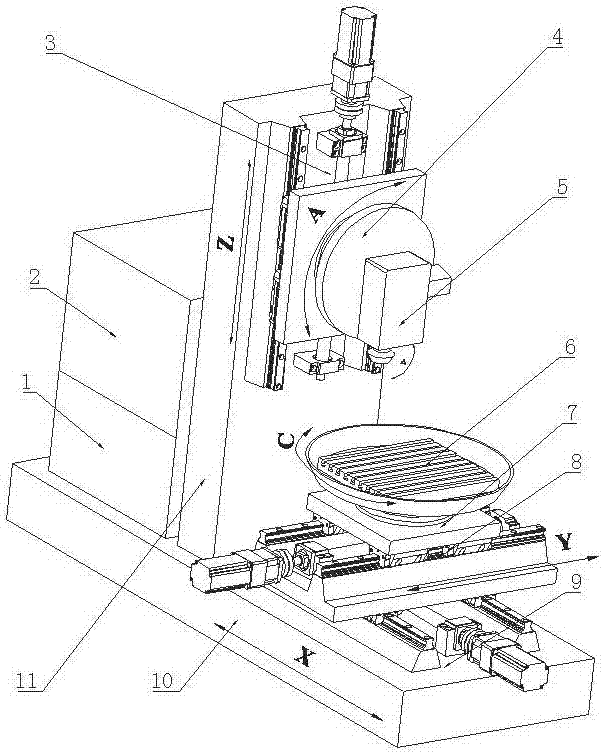

[0020] The polishing liquid recovery box 1 and the machine tool support 11 are respectively fixedly connected to the machine tool base 10, the polishing liquid online blending device 2 is fixedly connected to the top of the polishing liquid recovery box 1, the Z-direction feed mechanism 3 is fixedly connected to the machine tool support 11, and the Z-direction feed The mechanism 3 is connected with the A-axis swing mechanism 4, the A-axis swing mechanism 4 is connected with the polishing head tool system 5, the machine X-direction feed mechanism 9 is fixedly connected with the bed base 10, and the upper part of the X-direction feed mechanism 9 is connected with the Y-direction feed mechanism 8 are connected, and the Y-direction feed mechanism 8 is connected with the C-axis turntable 7 above.

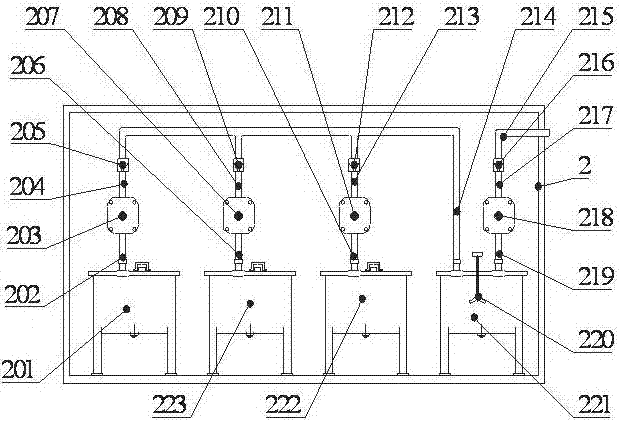

[0021] The structure of the polishing solution on-line blending device 2 is as follows: chemical reagent bottle one 201, chemical reagent bottle two 223, chemical reagent bottle three 222...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com