A kind of phase change energy storage material with pod structure and its preparation method and application

A phase-change energy storage material and a technology of phase-change materials, which are applied in the field of functional energy devices, can solve the problems that the stability and durability need to be further improved, the inability to realize large-scale continuous preparation, and the wide application of phase-change fibers are limited, and achieve continuous Controllable large-scale preparation, good cycle stability, uniform size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

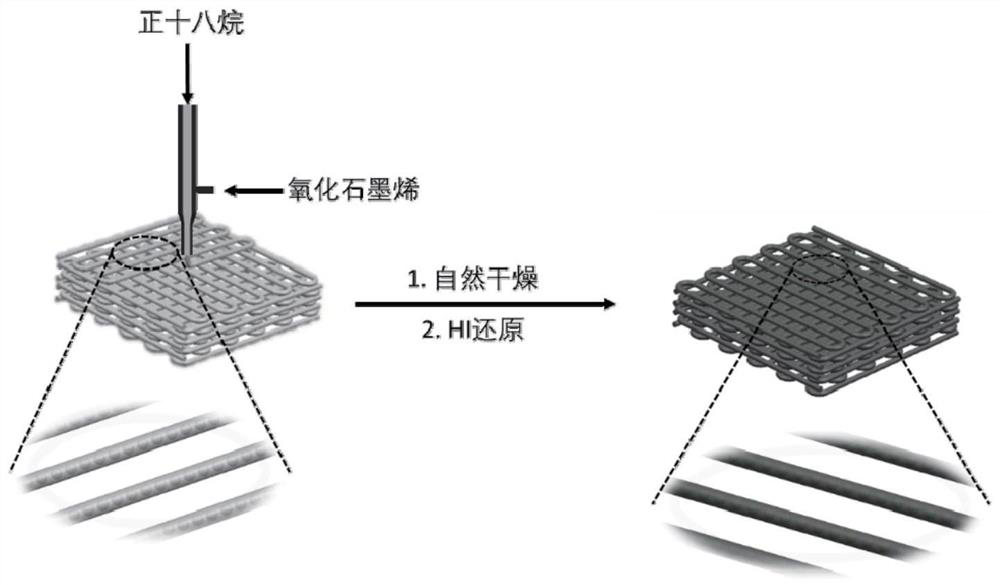

[0026] One aspect of the embodiments of the present invention provides a method for preparing a phase-change energy storage material with a pod structure, which includes:

[0027] Provide a liquid phase change material as the core layer printing ink;

[0028] Provide graphene oxide dispersion as shell printing ink;

[0029] And, using 3D printing technology, intermittently inject the core layer printing ink into the inner layer of the coaxial printing needle, and continuously inject the shell layer printing ink into the outer layer of the coaxial printing needle for coaxial printing, so as to obtain a Phase change energy storage materials with pod structure.

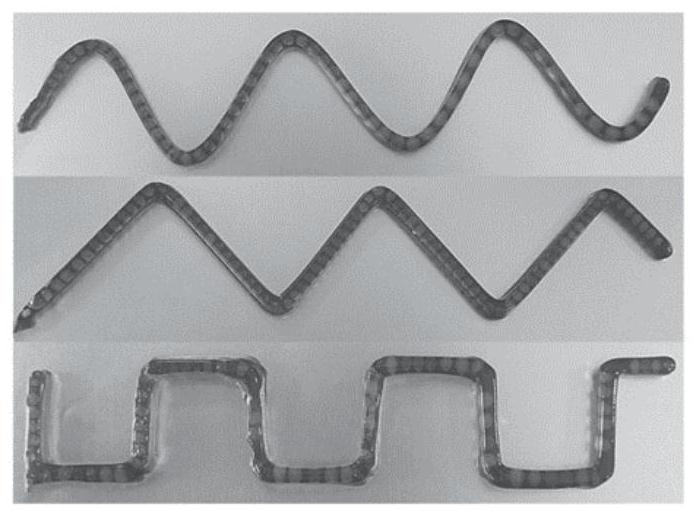

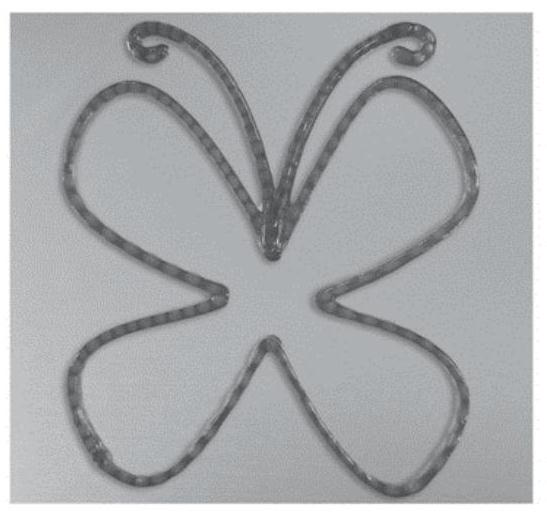

[0030] In the present invention, figure 1 It is a schematic flow chart of a preparation method of a phase-change energy storage material with a pod structure; Figure 2a-Figure 2f For 3D printing different shapes of phase change energy storage materials with pod structure without drying reduction treatment; Figure 3...

Embodiment 1

[0061] Heat the n-octadecane (OD) water bath to 30°C, connect the peristaltic pump to obtain the nuclear layer printing ink, the temperature of the graphene oxide dispersion is 10°C, control the speed of the peristaltic pump to 0.8rap, and the outer layer of the graphene oxide dispersion is solid The content is 40mg / ml (as shell printing ink), which is injected continuously using a syringe pump, the flow rate is controlled to 400μl / min, the temperature of the hot bed of the 3D printer is set to 20°C, and the operating speed of the printer is 3mm / s; aluminum foil is used as the printing substrate , set the core-shell solution in the inner and outer channels of the 3D printing coaxial needle, the height of the coaxial needle from the printer’s hot bed is 1mm, select the defined model of the 3D printer, and then perform drying and reduction treatment to obtain a phase transition with a pod structure Energy storage material (denoted as OD / graphene), the particle size of pod structu...

Embodiment 2

[0064] Heat the n-octadecane water bath to 30°C, connect the peristaltic pump to obtain the nuclear layer printing ink, the temperature of the graphene oxide dispersion is 20°C, control the speed of the peristaltic pump to 1.2rap, and the solid content of the outer graphene oxide dispersion is 45mg / ml (as shell printing ink), inject continuously using a syringe pump, control the flow rate to 600μl / min, set the temperature of the hot bed of the 3D printer to 25°C, and the operating speed of the printer to 3mm / s; use aluminum foil as the printing substrate, and The shell solution is set in the inner and outer channels of the 3D printing coaxial needle. The height of the coaxial needle from the printer’s hot bed is 1mm. The defined model of the 3D printer is selected, and then dried and reduced to obtain a phase change energy storage material with a pod structure. , the particle size of the pod structure is 0.8mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com