A high-efficiency rubber v-belt processing system

A processing system and rubber technology, applied in the direction of belts, other household appliances, household appliances, etc., can solve the problems of unstable quality of V-shaped conveyor belts, unsmooth production system, etc., to improve coating quality, improve coating efficiency, continuous wrapping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

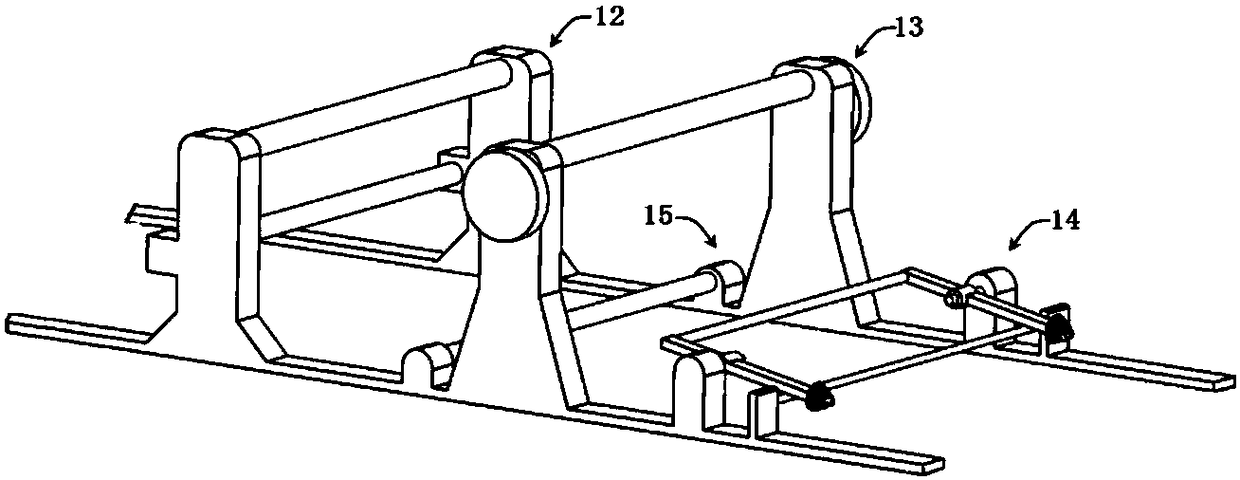

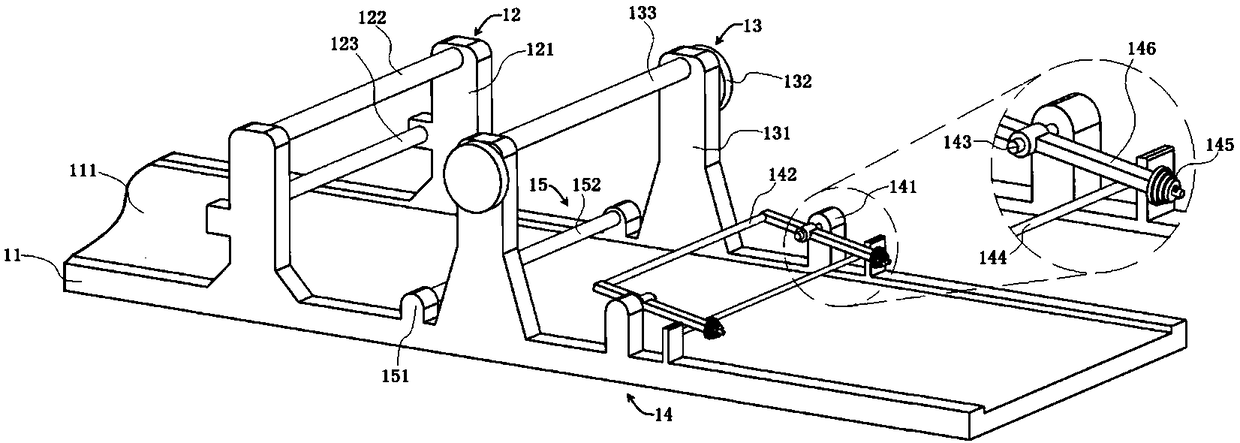

[0064] Such as Figure 18 As shown, a high-efficiency rubber V-belt processing system in this embodiment includes a rubber layer preparation device, a continuous coating device, a multi-functional molding integrated cutting device, a V-shaped conveyor belt core chamfering device and a vulcanization mold pressurization device, wherein: the adhesive layer preparation device is used for mixing raw materials to form an adhesive layer, and the continuous coating device includes a coating base 11 and a continuous coating unit, and the continuous coating The unit can wrap the inner liner on the rubber layer to make a tape; the multi-functional forming integrated cutting device is used to press and form the tape, and cut it to form a blank belt, and select the blank belt that meets the specifications as the belt core. The above-mentioned rubber layer preparation device includes a rubber layer calendering unit 16 and a rubber layer mixing unit 17; the V-shaped conveyor belt core chamfe...

Embodiment 2

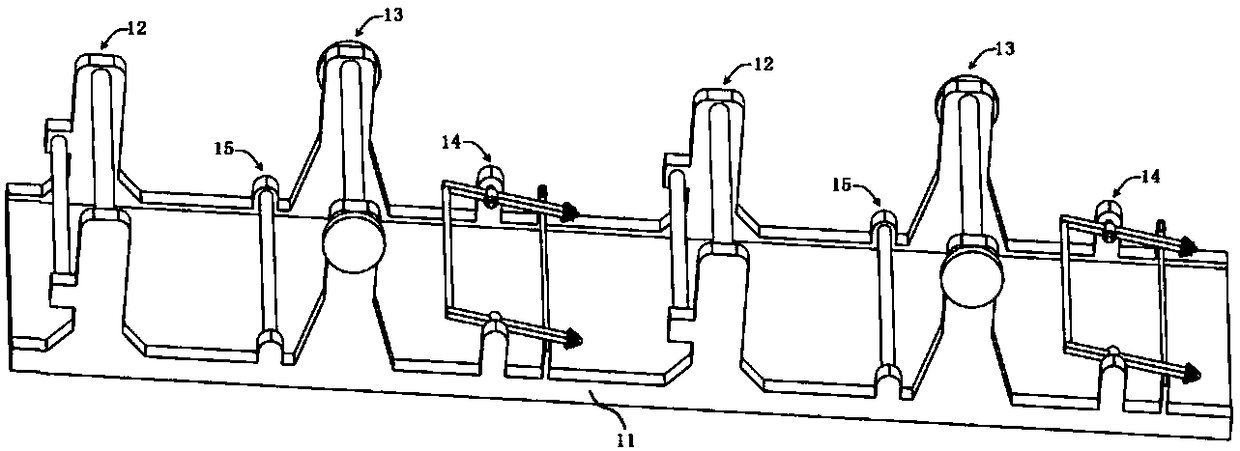

[0119] The basic content of this embodiment is the same as that of Embodiment 1. In the existing process where the rubber layer is continuously transported out by the rubber layer conveyor belt 111, the inner lining installed on the inner lining roller 122 is used up. In the process of replacing the inner lining In many cases, it is often necessary to stop the wrapping production of the tape. The continuous wrapping unit of the continuous wrapping device of the present invention is set to 2, and when the lining of the first adhesive tape liner wrapping unit is used up, the adhesive layer can continue to be combined with the second adhesive tape after being cut. The lining of the lining covering unit is glued, and the lining covering production of the tape is continued in the second tape covering mechanism 13, which realizes the continuous production of the tape covering the lining and greatly improves the packing of the tape lining. coverage efficiency. Of course, the continu...

Embodiment 3

[0121] The basic content of this embodiment is the same as that of Embodiment 1. On the basis of the above-mentioned adhesive tape lining coating unit, a continuous production device containing a lining tape in this embodiment includes a coating base 11, a continuous coating unit, adhesive layer calendering unit 16 and adhesive layer mixing unit 17; described coating base 11 is provided with adhesive layer transmission belt 111 along its length direction; described continuous coating unit is that this continuous coating unit is The above-mentioned adhesive tape lining coating unit; the continuous coating unit is installed on the top of the coating base 11, and one end of the coating base 11 is equipped with a rubber layer calendering unit 16 and a rubber layer mixing unit 17, and the rubber layer calendering unit 16 and The glue layer mixing unit 17 constitutes a glue layer preparation device. The raw materials for preparing the rubber layer are mixed by the rubber layer mixin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com