Compliant force control method based on fuzzy reinforced learning for mechanical arm

A technology of reinforcement learning and control methods, applied to manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problem of ensuring smooth and smooth human-computer interaction operations, difficulty in taking into account control accuracy and operating experience, and inapplicable robot active positioning requirements and other issues, to achieve the effect of smooth and natural human-computer interaction experience, good adaptive ability, and improved positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

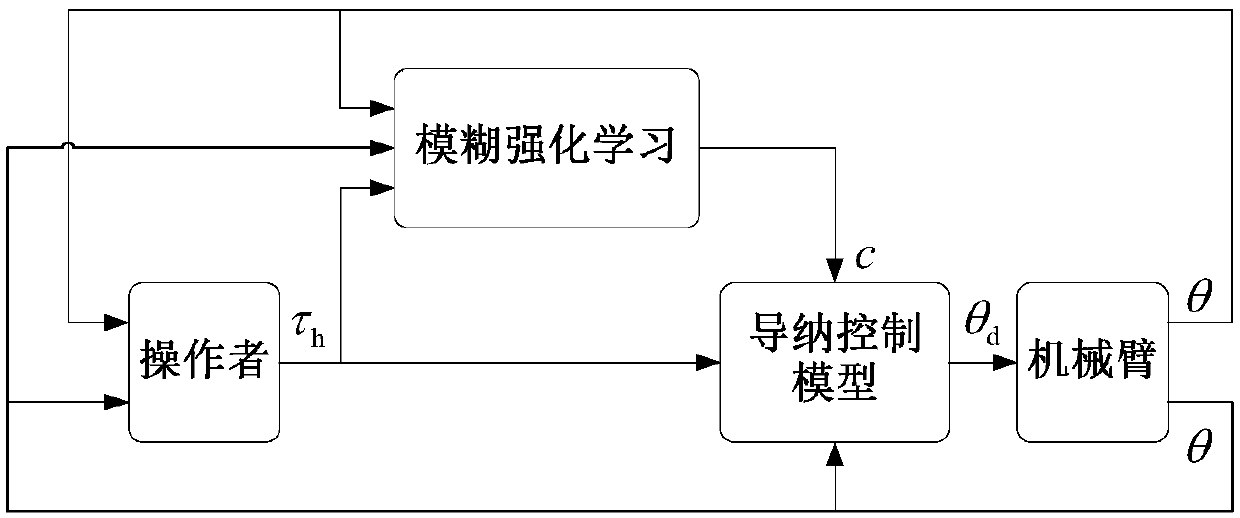

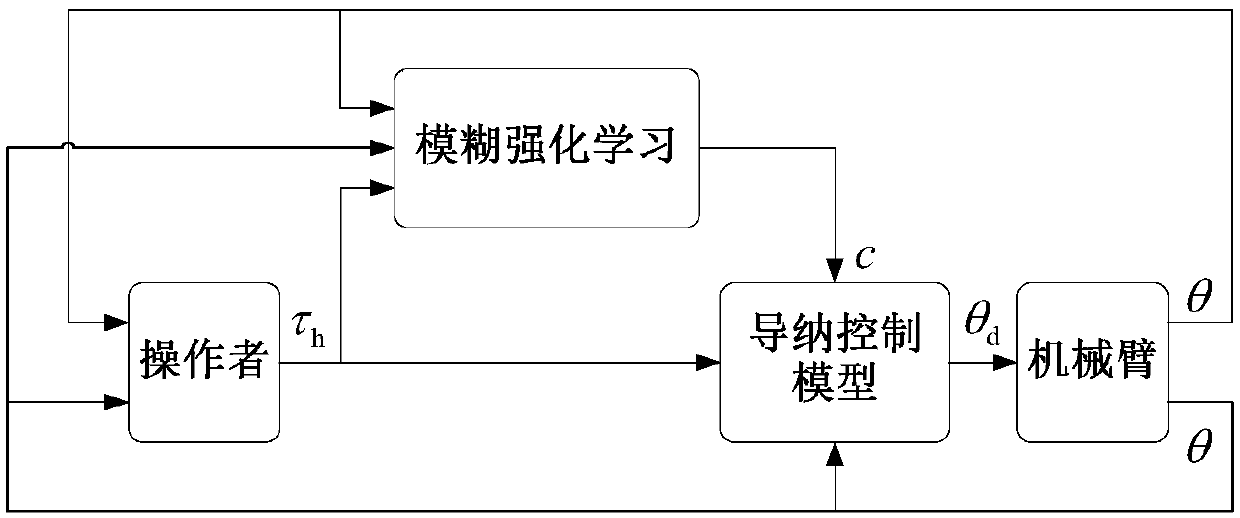

[0031] Such as figure 1 As shown, a method for controlling compliance of a robotic arm based on fuzzy reinforcement learning of the present invention includes the following steps:

[0032] S1: Establish an admittance control model.

[0033] S2: Obtain the motion state of the robotic arm, the external torque applied by the operator, and the environmental return value. The motion state of the robot arm includes the speed and acceleration of each active rotating joint of the robot arm.

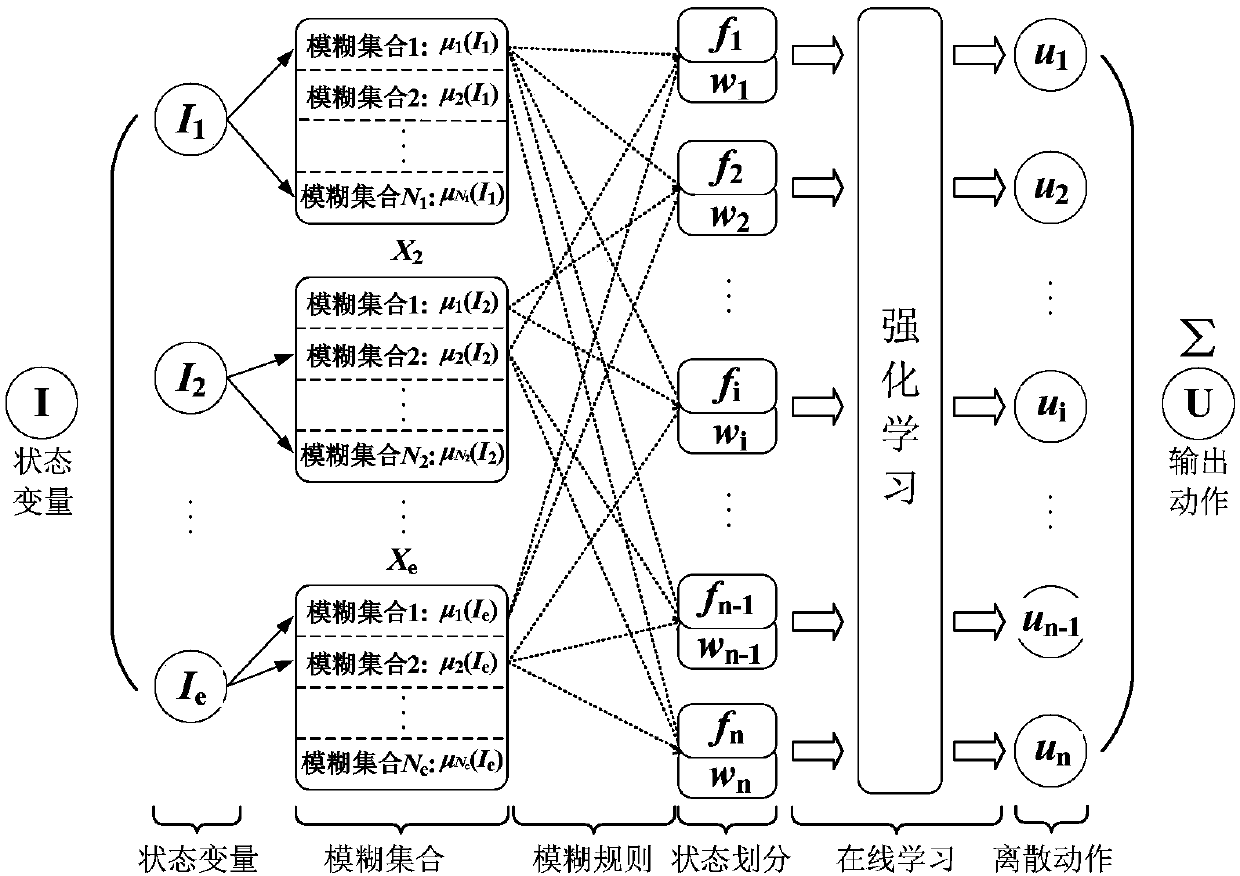

[0034] S3: In order to obtain the admittance model parameter adjustment strategy adapted to the current environment, according to the relevant information obtained in step S2, perform online training of the admittance model parameter adjustment strategy through fuzzy reinforcement learning until the algorithm converges, in order to obtain the current Variable admittance control model adapted to the environment. The fuzzy reinforcement learning in step S3 specifically includes the following steps:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com