Multi-nozzle real-time protection printing module for portable biological 3D printer

A 3D printer and printing module technology, applied in coating devices, additive processing, etc., can solve the problems of surface wear or bending failure, affecting the accuracy of printed products, not satisfying portability, etc., to achieve high adaptability, The effect of reducing control cost and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

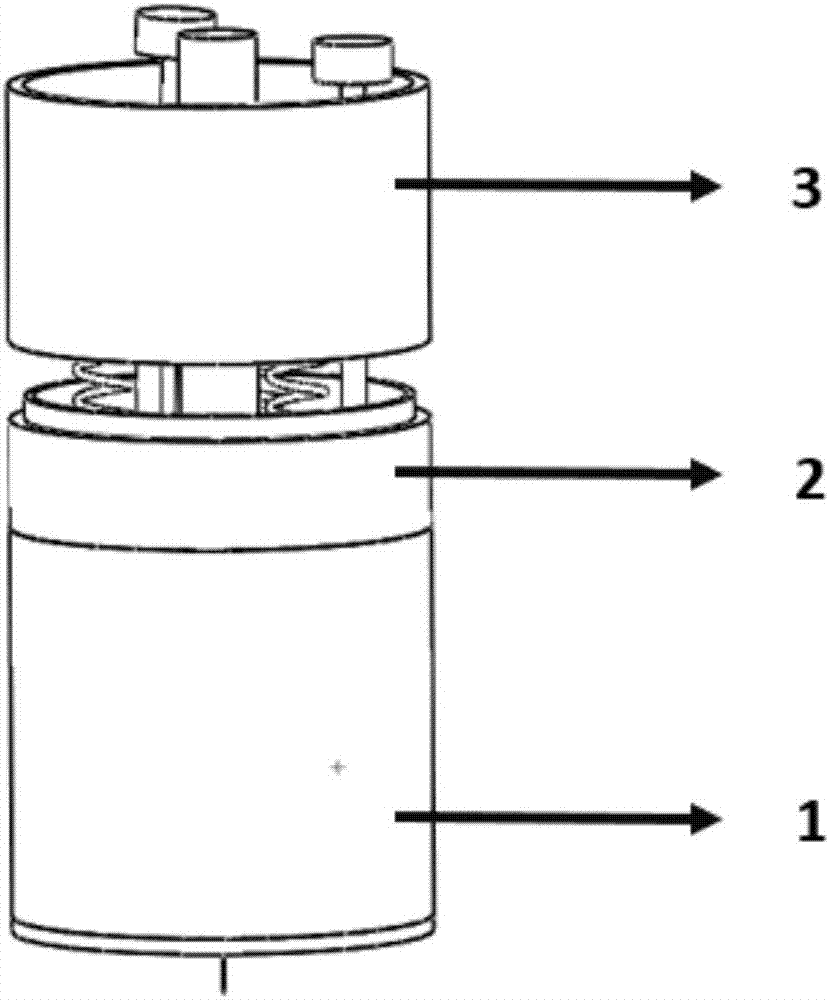

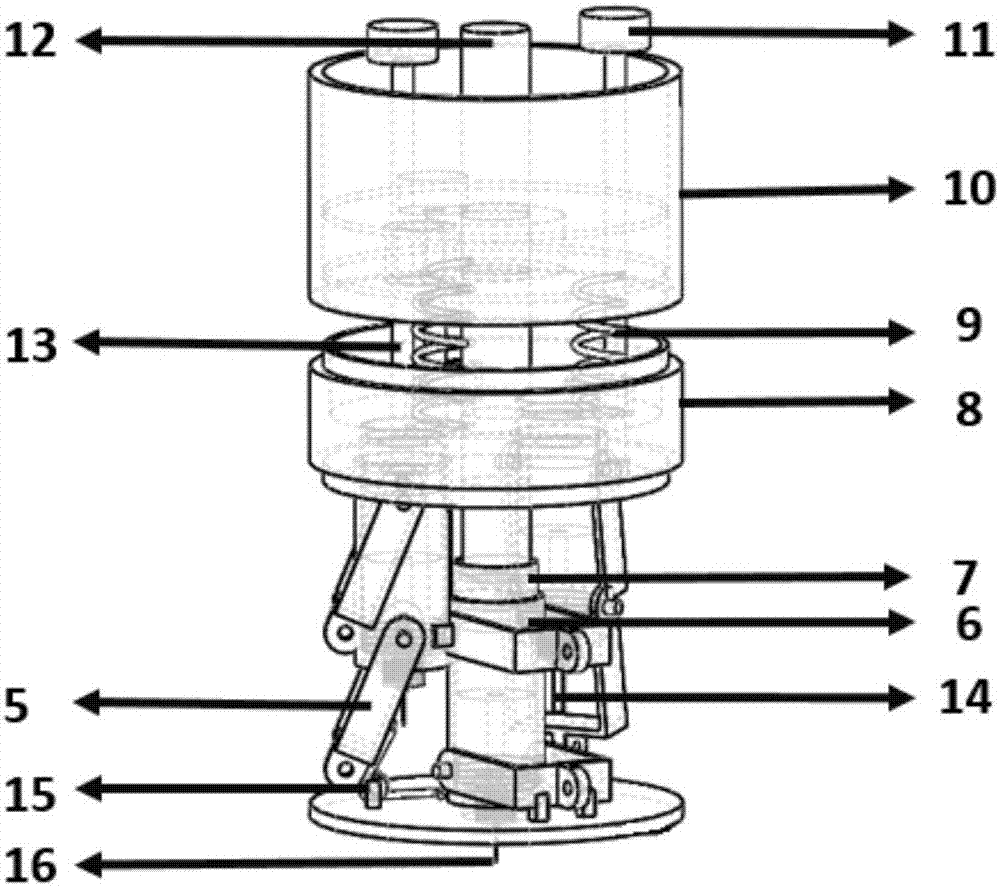

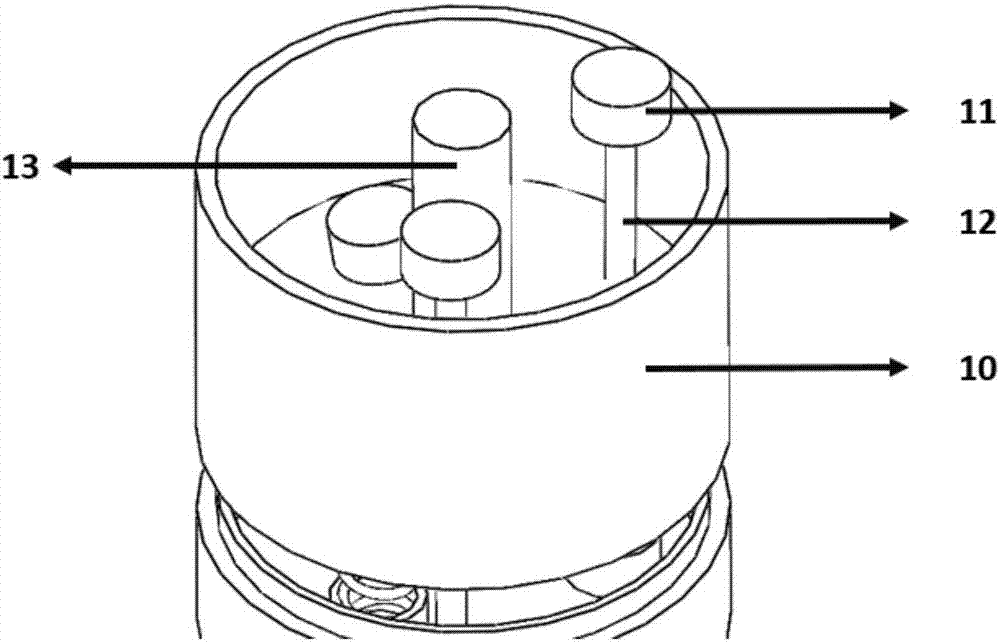

[0021] like Figure 1-5 As shown, the multi-nozzle instant protection printing module of the portable biological 3D printer of the present invention includes a casing, a replaceable multi-nozzle system 1, an instant power-off protection system 2, and an extrusion power system 3. The replaceable multi-nozzle system 1 includes three groups of needle systems, the three groups of needle systems are evenly arranged in the shell,

[0022] Each needle system includes a rocker 5, a torsion spring 15, a liquid storage bin 7, a liquid storage bin support 6, a pressure rod 13, and a button 11; the rocker 5 includes two upper and lower rockers, and the liquid storage bin support 6 is connected to the lower end of the pressure bar 13; one end of the lower rocker is hinged on the liquid storage tank support 6, and one end of the upper rocker is hinged at the junction of the liquid storage support 6 and the pressure bar 13; the upper rocker and the lower rocker The other end of the rocker i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com