Two-dimensional black phosphorus material and preparation method thereof

A technology of black phosphorus and red phosphorus, which is applied in the field of two-dimensional black phosphorus materials and its preparation, can solve the problems of high price and undiscovered sales of two-dimensional black phosphorus materials, and achieve low cost, large market potential, and fast and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

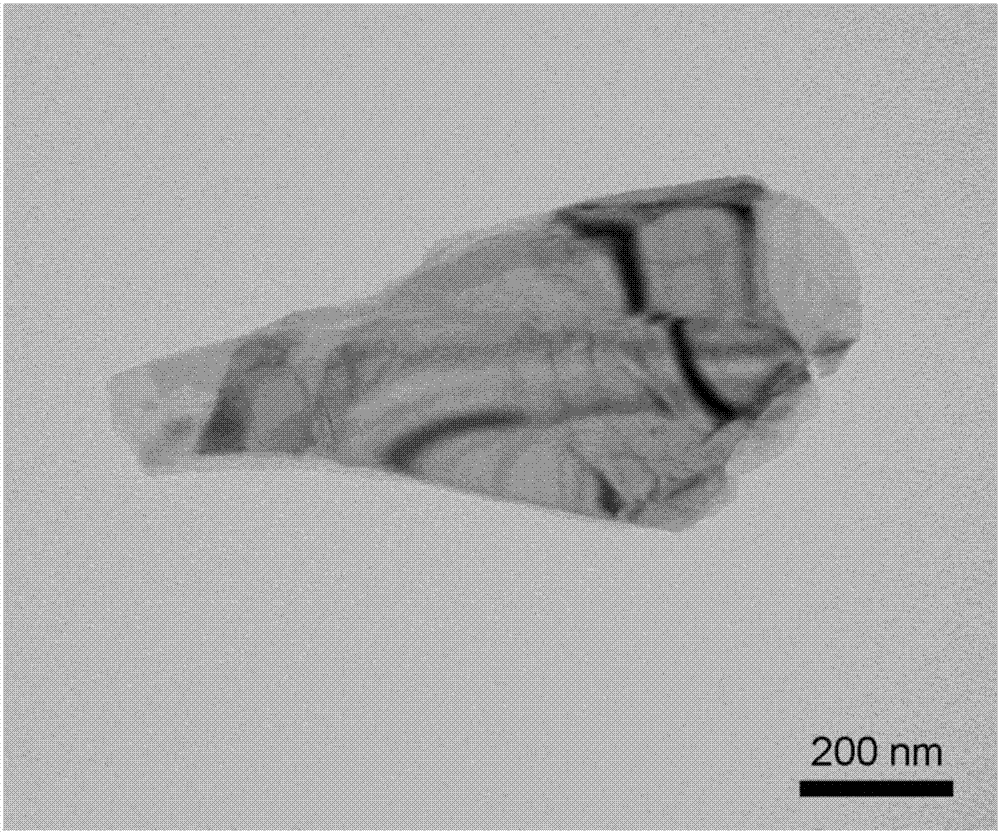

[0030] A preparation method of a two-dimensional black phosphorus material proposed by the present invention comprises the following steps: grinding block black phosphorus, first dissolving the ground block black phosphorus in hot toluene, ultrasonically washing for 1 min, centrifuging for 6 min, and centrifuging The rotation speeds were all 13000 rpm, and then the steps of ultrasonic washing with hot toluene and centrifugation were repeated 3 times; then the centrifuged product was dissolved in acetone, ultrasonically washed for 1 min, and centrifuged for 6 min at 13000 rpm, and then the acetone ultrasonic washing, Centrifuge step 3 times; add N-methylpyrrolidone, ultrasonically peel for 24 hours, centrifuge the material after ultrasonic peeling at a speed of 1600 rpm for 9 minutes, take the supernatant, then centrifuge at a speed of 14000 rpm for 9 minutes, and take the solid material Obtain the mixed material containing two-dimensional black phosphorus; dissolve the mixed ma...

Embodiment 2

[0033] A preparation method of a two-dimensional black phosphorus material proposed by the present invention comprises the following steps: grinding block black phosphorus, first dissolving the ground block black phosphorus in hot toluene, ultrasonically washing for 2 minutes, centrifuging for 4 minutes, centrifuging The rotation speeds were all 14000 rpm, and then the hot toluene ultrasonic washing and centrifugation steps were repeated twice; then the centrifuged product was dissolved in acetone, ultrasonically washed for 2 min, and centrifuged for 4 min at 14000 rpm, and then the acetone ultrasonic washing, Centrifuge twice; add N-methylpyrrolidone, ultrasonically peel for 25 hours, centrifuge the material after ultrasonic peeling at a speed of 1500 rpm for 11 minutes, take the supernatant, then centrifuge at a speed of 13000 rpm for 11 minutes, and take the solid material Obtain a mixed material containing two-dimensional black phosphorus; dissolve the mixed material contai...

Embodiment 3

[0036] The preparation method of a two-dimensional black phosphorus material proposed by the present invention comprises the following steps: grinding the black phosphorus in bulk, first dissolving the ground black phosphorus in hot toluene, ultrasonically washing for 1.5 minutes, centrifuging for 5 minutes, The centrifugation speed is 13500 rpm, then repeat the hot toluene ultrasonic washing and centrifugation steps twice; then dissolve the centrifuged product in acetone, ultrasonically wash for 1.5 min, and centrifuge for 5 min at 13500 rpm, then repeat the acetone ultrasonic Washing and centrifugation steps 3 times; adding N-methylpyrrolidone, ultrasonic stripping for 24.5 hours, centrifuging the material after ultrasonic stripping at a speed of 1550 rpm for 10 min, taking the supernatant, and then centrifuging at a speed of 13500 rpm for 10 min, Take the solid material to obtain a mixed material containing two-dimensional black phosphorus; dissolve the mixed material contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com