A kind of polyether composite cement grinding aid and preparation method thereof

A cement grinding aid and composite cement technology, applied in the field of grinding aids, can solve the problems of insufficient compressive and flexural strength, unstable quality of cement grinding aids, etc., and achieve the effect of improving the compressive capacity and increasing the strength of cement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

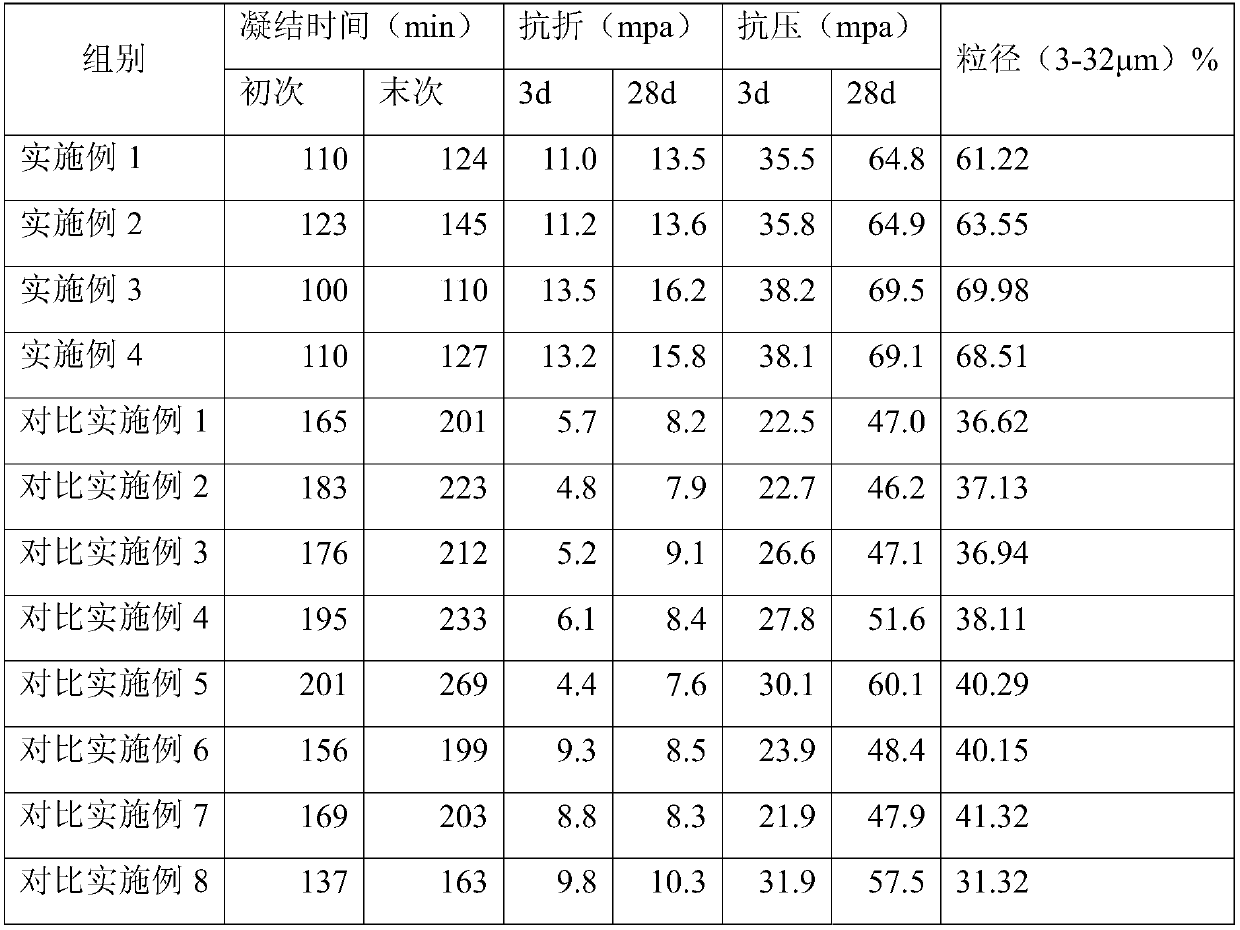

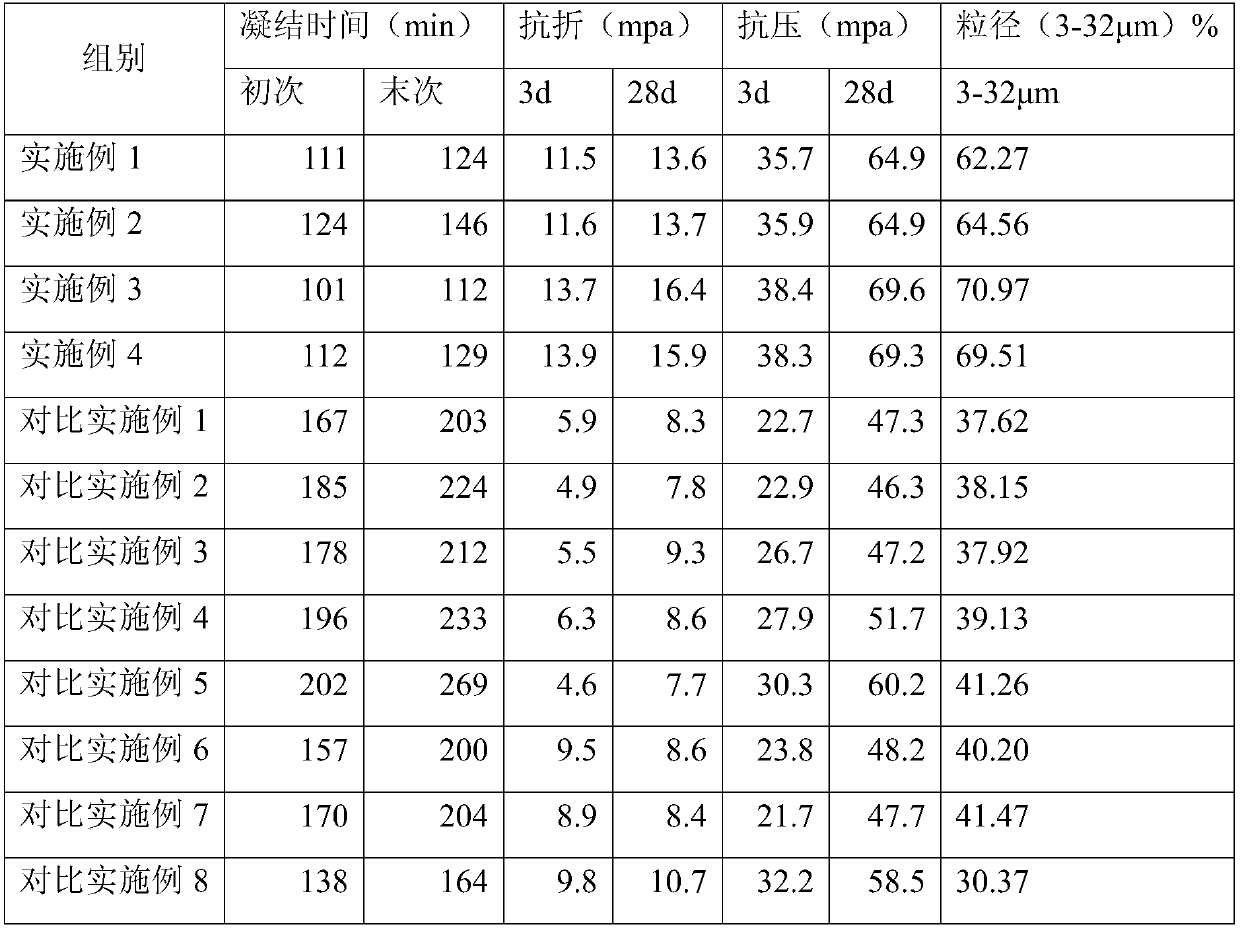

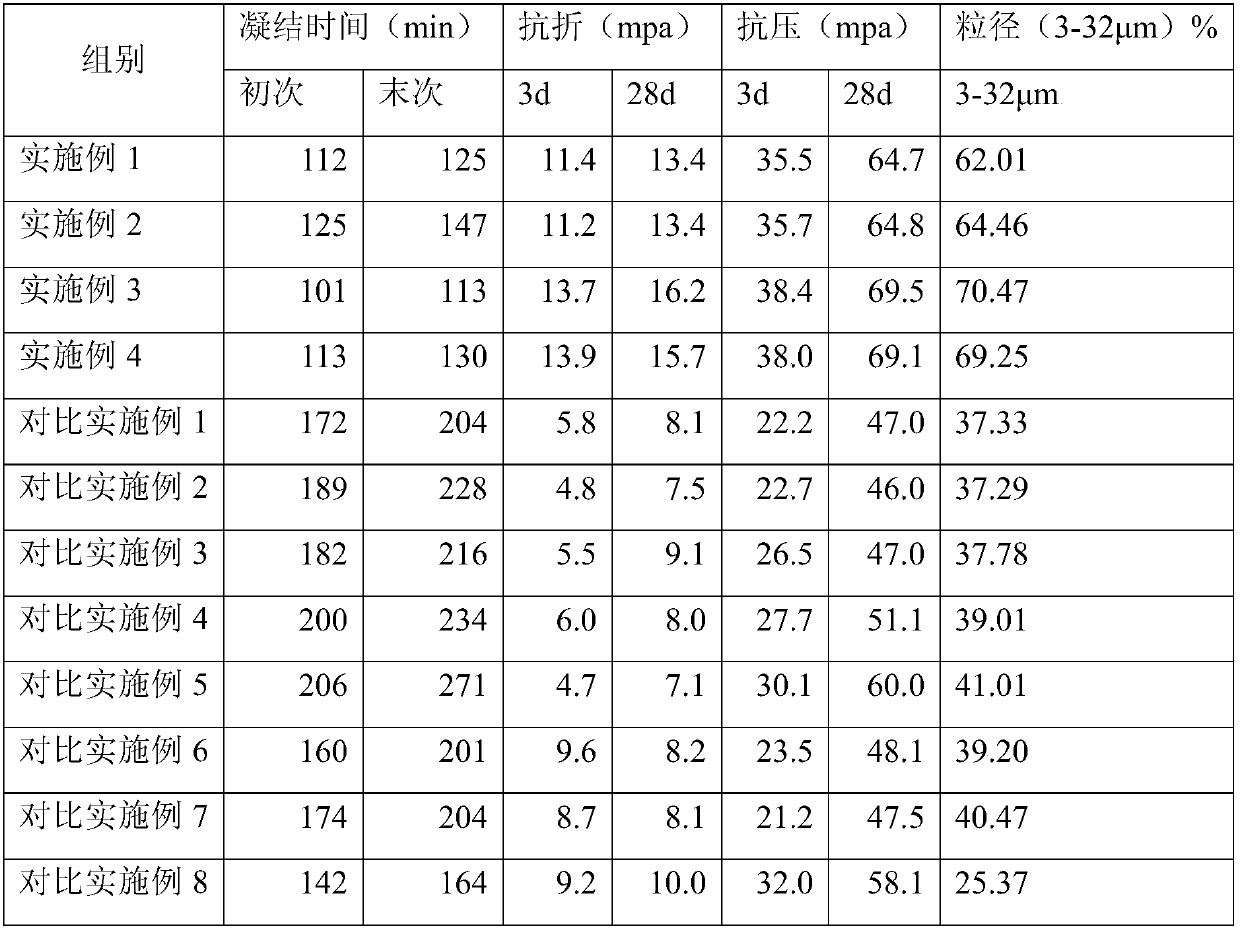

Examples

Embodiment 1

[0028] A kind of polyether compound cement grinding aid, is made up of the raw material of following parts by weight: polyethylene glycol ether, polyol, poloxamer, polyoxyethyl castor oil, water ratio is=15:10:1: 0.5:70.

[0029] Among them, the ratio of polyethylene glycol, sorbitol, triethanolamine, propylene glycol and isopropanol in the polyol is 1:1:1:1:1, and the molecular weight of polyethylene glycol is 4000.

[0030] The preparation method is:

[0031] 1) Mix polyethylene glycol ether with polyoxyethyl castor oil, add poloxamer to form a mixture, heat the mixture at a temperature of 60°C, and react chemically for 5 hours to produce compound I;

[0032] 2) Add polyhydric alcohol and water to compound I after step a and mix evenly to obtain a finished product.

Embodiment 2

[0034] A kind of polyether composite cement grinding aid, is made up of the raw material of following parts by weight: polyethylene glycol ether, polyol, poloxamer, polyoxyethyl castor oil, water ratio is=25:30:3: 1:90.

[0035] Among them, the ratio of polyethylene glycol, sorbitol, triethanolamine, propylene glycol and isopropanol in the polyol is 1:1:1:1:1, and the molecular weight of polyethylene glycol is 4000.

[0036] The preparation method is:

[0037] 1) Mix polyethylene glycol ether with polyoxyethyl castor oil, add poloxamer to form a mixture, heat the mixture at a temperature of 100° C., and react chemically for 5 hours to produce compound I;

[0038] 2) Add polyhydric alcohol and water to compound I after step a and mix evenly to obtain a finished product.

Embodiment 3

[0040] A kind of polyether composite cement grinding aid, is made up of the raw material of following parts by weight: polyethylene glycol ether, polyol, poloxamer, polyoxyethyl castor oil, water ratio is=18:20:2: 0.7:80.

[0041]Among them, the ratio of polyethylene glycol, sorbitol, triethanolamine, propylene glycol and isopropanol in the polyol is 1:1:1:1:1, and the molecular weight of polyethylene glycol is 4000.

[0042] The preparation method is:

[0043] 1) Mix polyethylene glycol ether with polyoxyethyl castor oil, add poloxamer to form a mixture, heat the mixture at a temperature of 80° C., and react chemically for 5 hours to produce compound I;

[0044] 2) Add polyhydric alcohol and water to compound I after step a and mix evenly to obtain a finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com