Highly-efficient energy-saving atmospheric and vacuum deep distillation process based on clear cut

A high-efficiency, energy-saving, atmospheric and vacuum technology, applied in the distillation control/regulation of hydrocarbon oil, petroleum industry, hydrocarbon distillation, etc., can solve the problem of unclear cutting of oil products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

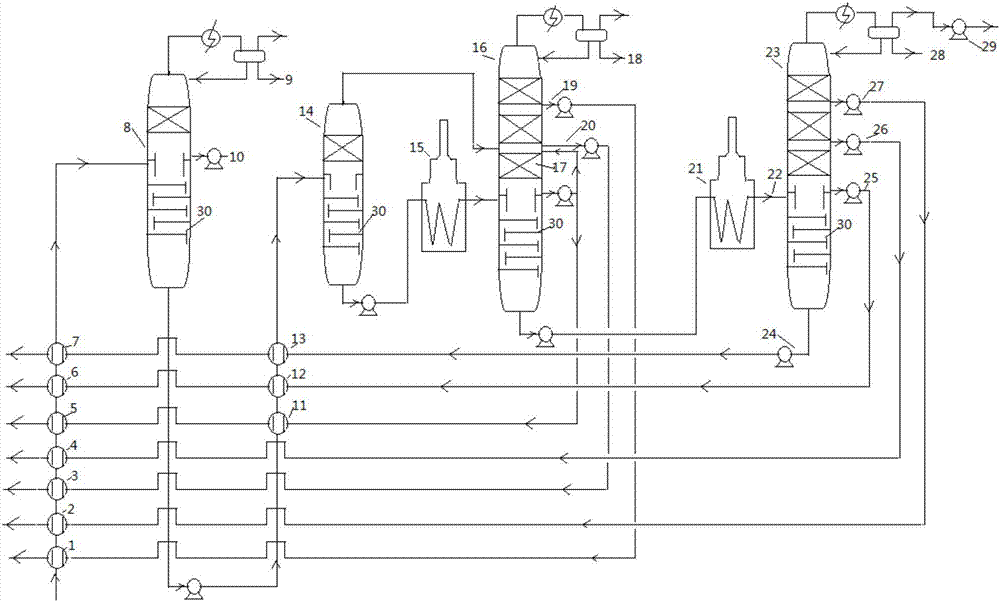

[0024]Shengli crude oil passes through heat exchanger 1 to heat exchanger 7 and first-line diesel oil, minus first-line wax oil, second-line diesel oil, second-line wax oil, heavy diesel oil after one change, third-line wax oil after one change, and vacuum residue after one change A stage of heat exchange is carried out sequentially, and the Shengli crude oil is preheated to 180°C-240°C; after the heat exchange, the Shengli crude oil enters the flash section of the primary distillation tower (8), and enters the rectification section of the primary distillation tower (8) after the vapor phase is defoamed to be separated to obtain Straight-run gasoline (9) and light diesel oil (10), the liquid phase passes through the deep-drawing stripping tray (30) that increases at the bottom of the initial distillation tower (8) and uses less than 1% superheated steam to strengthen stripping, and the bottom of the tower In the oil, the fraction content before the initial distillation feed tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com