A high density, high calorific value jet fuel

A jet fuel, high-density technology, applied in the direction of fuel, liquid carbon-containing fuel, processing hydrocarbon oil, etc., can solve the problems of low jet fuel density and high cost, achieve high conversion rate, increase endurance, and environmental protection costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

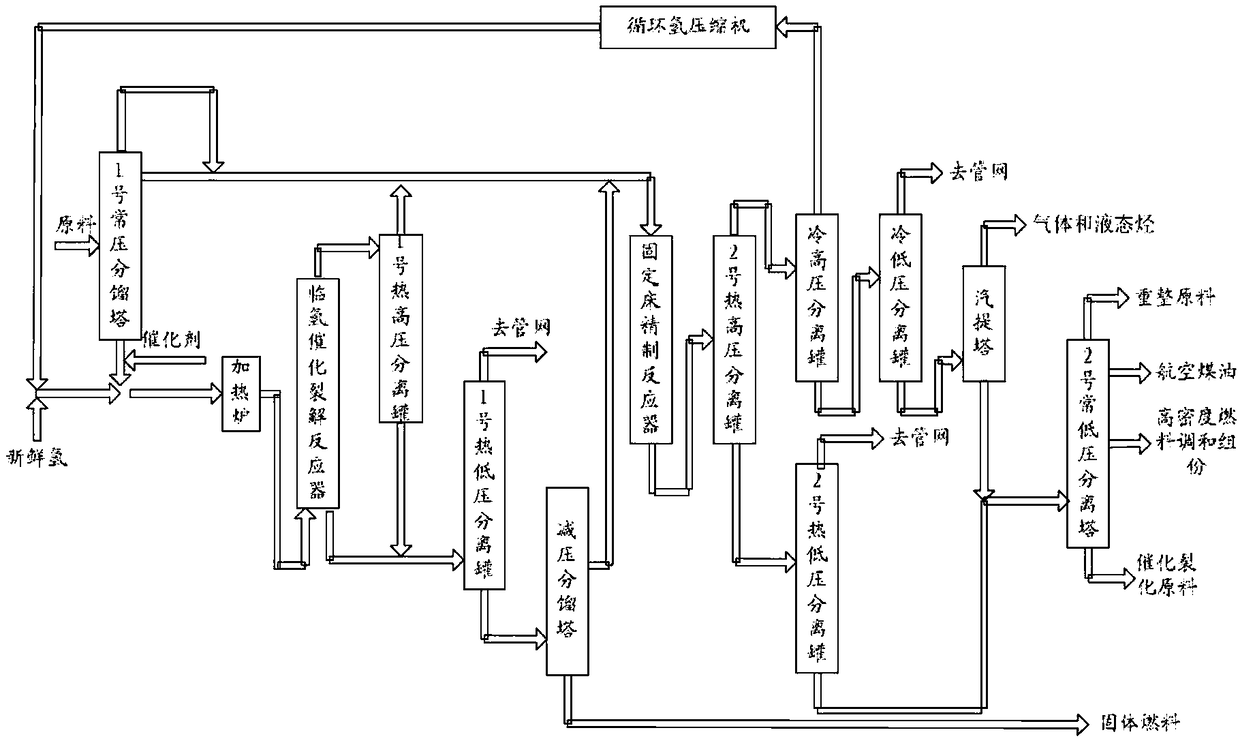

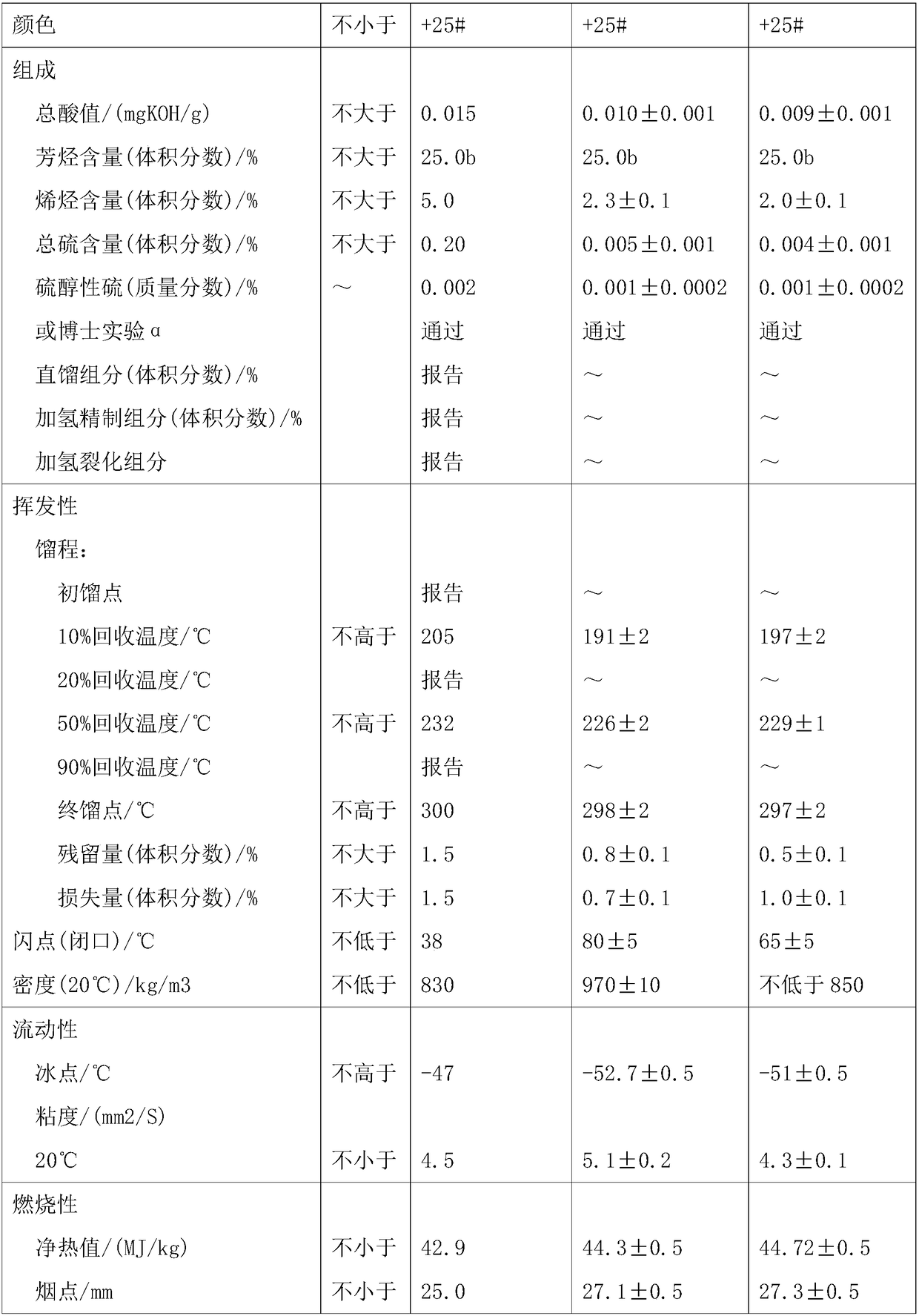

[0058] see figure 1 , a high-density, high-calorific-value jet fuel, which is formed by mixing components with a distillation range of 180-300°C in F-T synthetic coal-to-oil and high-density fuel blending components at a mass ratio of 1:4, wherein the The above-mentioned high-density blending components are naphthenes, aromatics and tail oils with a distillation range of 180-300°C obtained through hydrotreating with inferior heavy oil as raw material. The specific preparation process is as follows:

[0059] One, first put the inferior heavy oil into No. 1 atmospheric fractionation tower to obtain light fraction and atmospheric residue, then mix the atmospheric residue with a catalyst to obtain a mixture, wherein the inferior heavy oil is coal tar, The catalyst is a molybdenum-nickel oil solvent catalyst with a molybdenum-nickel mass ratio of 1:4, and the amount of the molybdenum-nickel oil solvent catalyst is 0.015% of hydrogen;

[0060] 2. First mix the mixture with hydrogen...

Embodiment 2

[0067] Step is with embodiment 1, and difference is:

[0068] In the jet fuel, the mass ratio of components with a distillation range of 180-300°C and high-density fuel blending components in F-T synthetic coal-to-oil is 3:7;

[0069] In the described process one, the inferior heavy oil is ethylene tar, and the catalyst is a molybdenum-nickel oil solvent catalyst with a molybdenum-nickel mass ratio of 1:1, and the consumption of the molybdenum-nickel oil solvent catalyst is 0.02% of hydrogen;

[0070] In described technique two, the reaction condition of facing hydrocracking reactor is:

[0071] The reaction pressure is 16MPa, the reaction temperature is 445°C, and the total feed volume space velocity is 1.0h -1 , the volume ratio of hydrogen to oil is 800;

[0072] In the process three, the hydrogenation upgrading catalyst is Co-Ni / Al 2 o 3 Hydrogenation upgrading catalyst, its active metal mass is 30% of the total mass of hydrogenation upgrading catalyst, the reaction co...

Embodiment 3

[0075] Step is with embodiment 1, and difference is:

[0076] In the jet fuel, the mass ratio of components with a distillation range of 180-300°C and high-density fuel blending components in F-T synthetic coal-to-oil is 1:2;

[0077] In the described process one, the inferior heavy oil is a catalytic oil slurry, and the catalyst is a molybdenum-nickel oil solvent catalyst with a molybdenum-nickel mass ratio of 4:1, and the consumption of the molybdenum-nickel oil solvent catalyst is 0.04% of hydrogen;

[0078] In described technique two, the reaction condition of facing hydrocracking reactor is:

[0079] The reaction pressure is 23MPa, the reaction temperature is 470°C, and the total feed volume space velocity is 1.5h -1 , the volume ratio of hydrogen to oil is 1200;

[0080] In the process three, the hydrogenation upgrading catalyst is Co-W / Al 2 o 3 Hydrogenation upgrading catalyst, its active metal mass is 40% of the total mass of hydrogenation upgrading catalyst, the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com