Vacuum induction heating and percolation method and device for gear surface

A vacuum induction and thermal infiltration technology, applied in solid diffusion coating, metal material coating process, coating and other directions, can solve surface oxidation, there is no method and device suitable for vacuum induction heating diffusion infiltration on gear surface, and work efficiency It is not high enough to achieve the effect of bright surface, saving man-hours and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

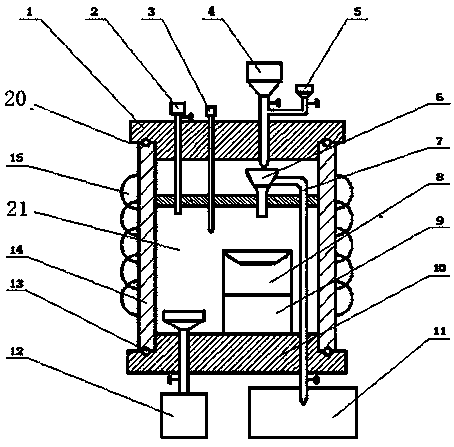

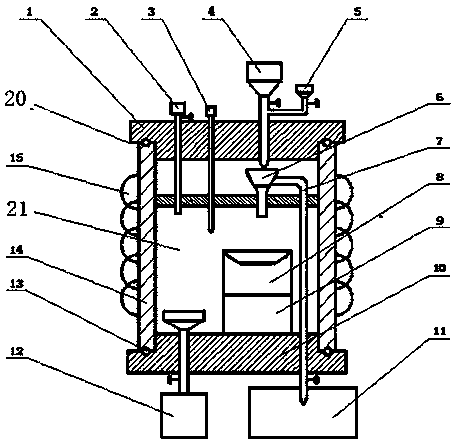

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] The present invention provides a kind of vacuum induction heating infiltration method on the surface of the gear, and its technological operation is carried out according to the following steps:

[0028] 1. Place the gear workpiece to be processed on the workbench in the inner cavity of the reaction device, close the sealing cover to seal the inner cavity of the reaction device, and open the vacuum device connected to the vacuum interface for vacuuming. When the vacuum in the inner cavity meets the use requirements , close the vacuum device.

[0029] 2. Open the valve of the feed hopper provided on the reaction device, and put the powder raw material required for the infiltration treatment into the inner cavity of the reaction device and fall into the filter device;

[0030] 3. The powder raw material is screened through the filter de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com