Tunnel trolley auxiliary grouting device and process

A technology of grouting device and trolley, which is applied in the direction of tunnels, tunnel linings, shaft equipment, etc., can solve problems such as incompleteness and construction joint diseases, and achieve the effects of reducing cracking, improving force bearing capacity, and reducing the risk of disasters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

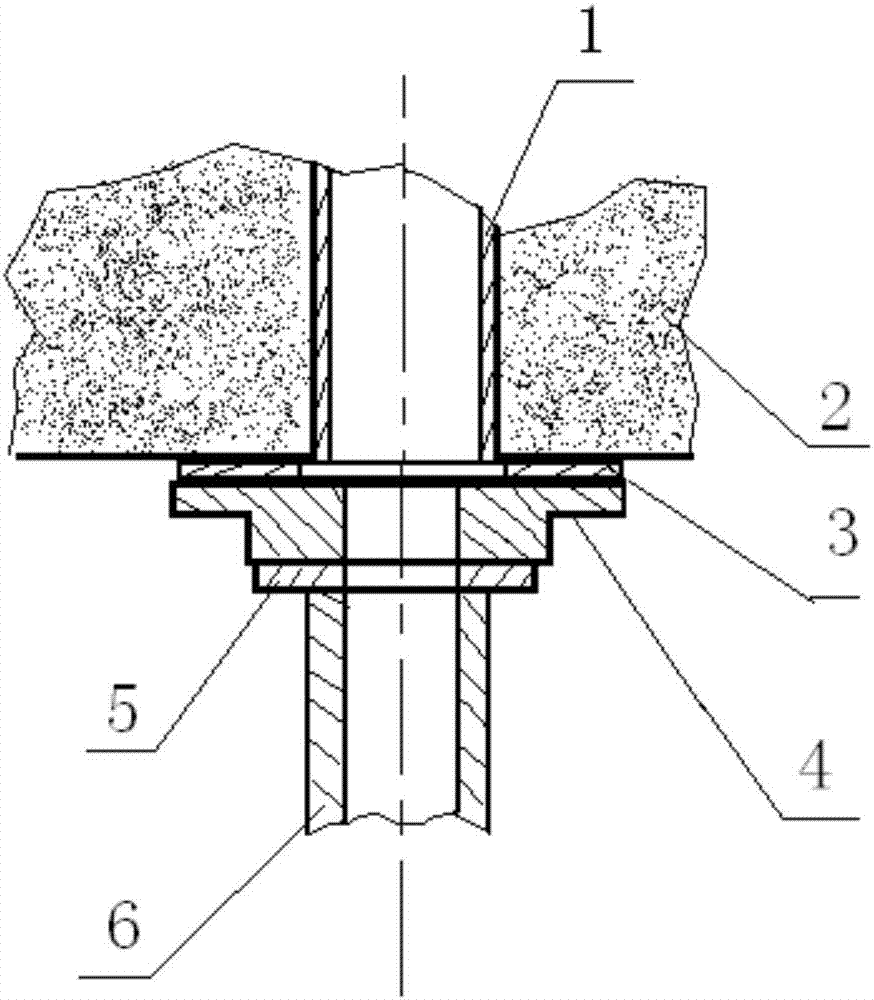

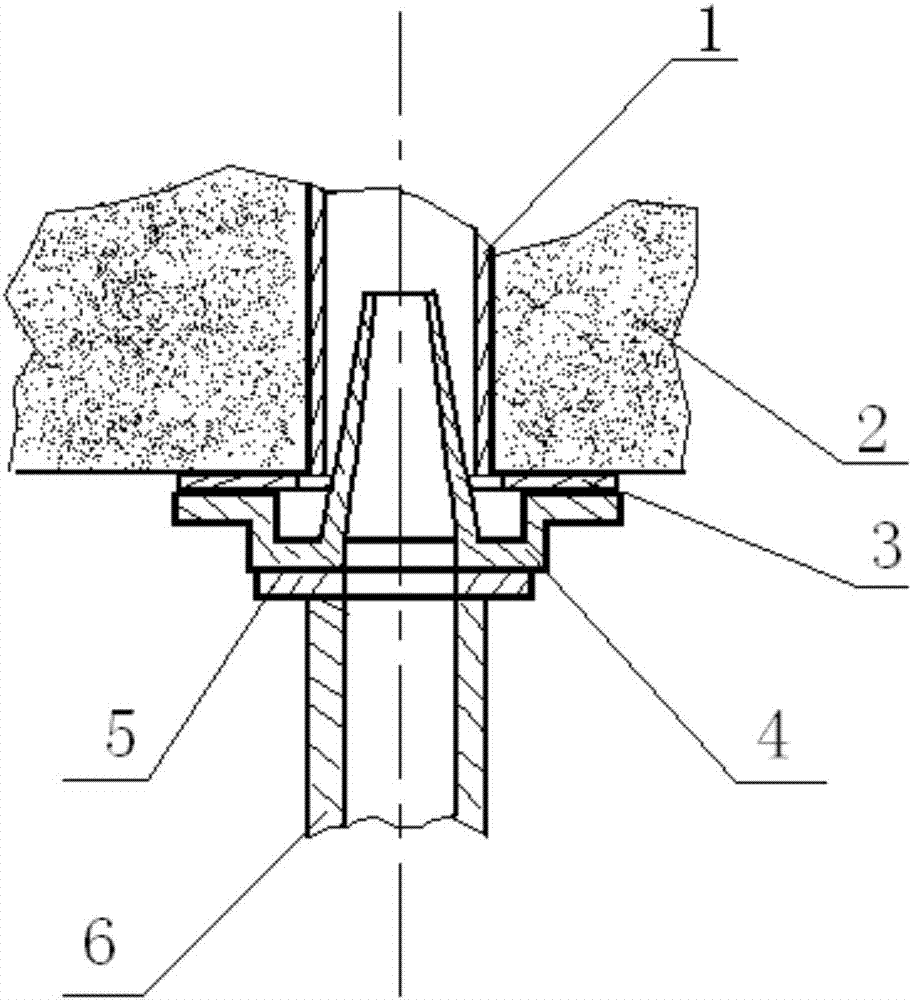

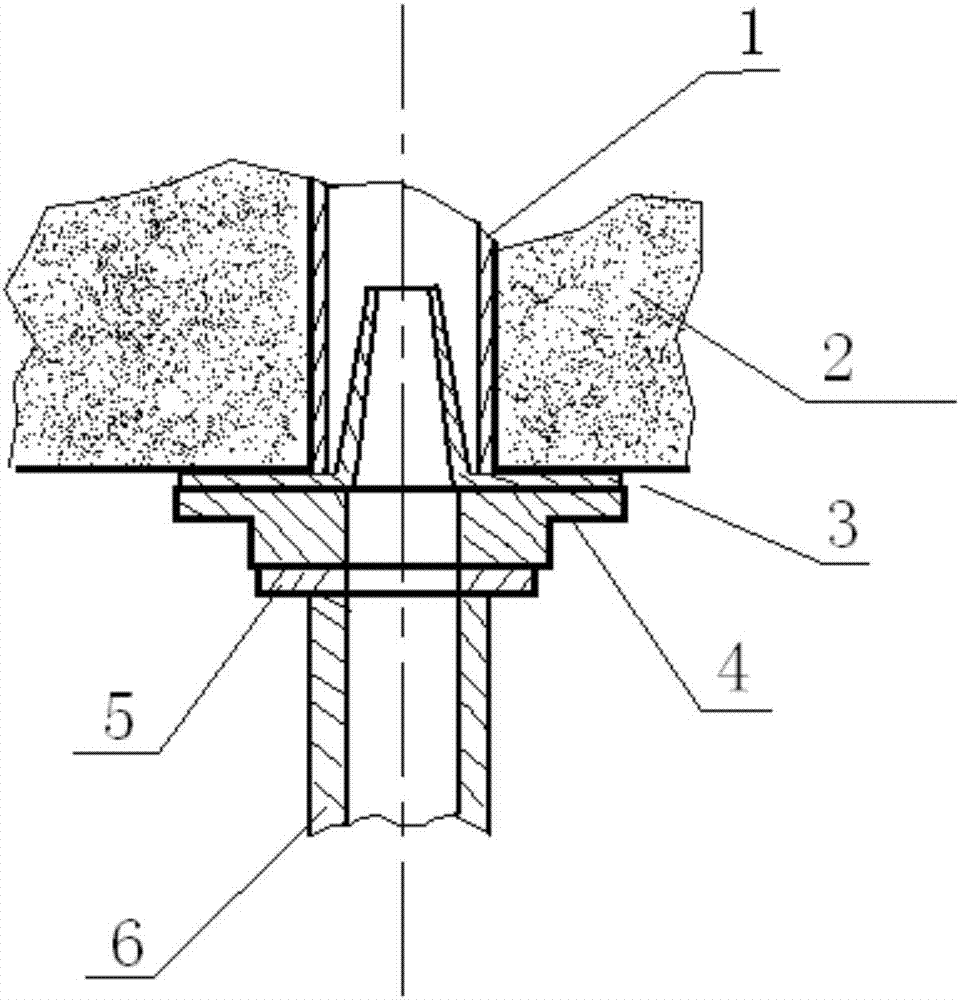

[0072] This embodiment provides an auxiliary grouting device for tunnel trolley, which includes a connecting device and a supporting device, wherein, when the auxiliary grouting device for tunnel trolley is in use, the connecting device is used to connect the RPC grouting pipe and For the grouting machine, for example, the connection device can be connected to the grouting machine through a pressure-resistant grouting pipe. In this embodiment, the RPC grouting pipe is embedded in the concrete. When the grouting machine is working, the The grout is injected into the RPC grout pipe through the pressure resistant grout pipe.

[0073] Specifically, refer to figure 1 , the connecting device includes a rubber pad 3, a connecting sealing disc 4 and a quick connector 5;

[0074] The rubber pad is arranged under the concrete, and when an external force is applied to the connecting sealing disk, the connecting sealing disk exerts pressure on the rubber pad, thereby making the gap betwe...

Embodiment 2

[0123] refer to Figure 23 , the present embodiment provides a railway tunnel lining trolley belt mold grouting auxiliary grouting process, which includes:

[0124] The first step: the initial installation and modification of the trolley

[0125] The initial installation and modification of the trolley adopts different modification methods according to the use of different support devices; if the first support device is used, one or more support bases need to be set at an appropriate position on the top floor of the trolley, and other components of the first support device Install according to the relative position described in the first support device; if the second support device is used, it is necessary to set a support base at an appropriate position on the top floor of the trolley, and the other parts of the second support device are as described in the second support device. The above-mentioned relative position is installed; if the third support device is used, it is n...

Embodiment 3

[0154] refer to Figure 24 , the present embodiment provides a railway tunnel lining trolley belt mold grouting auxiliary grouting process, which includes:

[0155] The first step: the initial installation and modification of the trolley

[0156] The initial installation and modification of the trolley adopts different modification methods according to the use of different support devices; if the first support device is used, one or more support bases need to be set at an appropriate position on the top floor of the trolley, and other components of the first support device Install according to the relative position described in the first support device; if the second support device is used, it is necessary to set a support base at an appropriate position on the top floor of the trolley, and the other parts of the second support device are as described in the second support device. The above-mentioned relative position is installed; if the third supporting device is used, it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com