Extender engine cooling water cavity structure

A technology for cooling water cavity and engine, which is applied in the direction of engine cooling, machine/engine, engine components, etc. It can solve the problems of small contact area between cooling water and cylinder block, reduced overall service life of the engine, and low cooling water heat. , to achieve the effect of lowering the operating temperature, increasing the service life and increasing the water storage volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

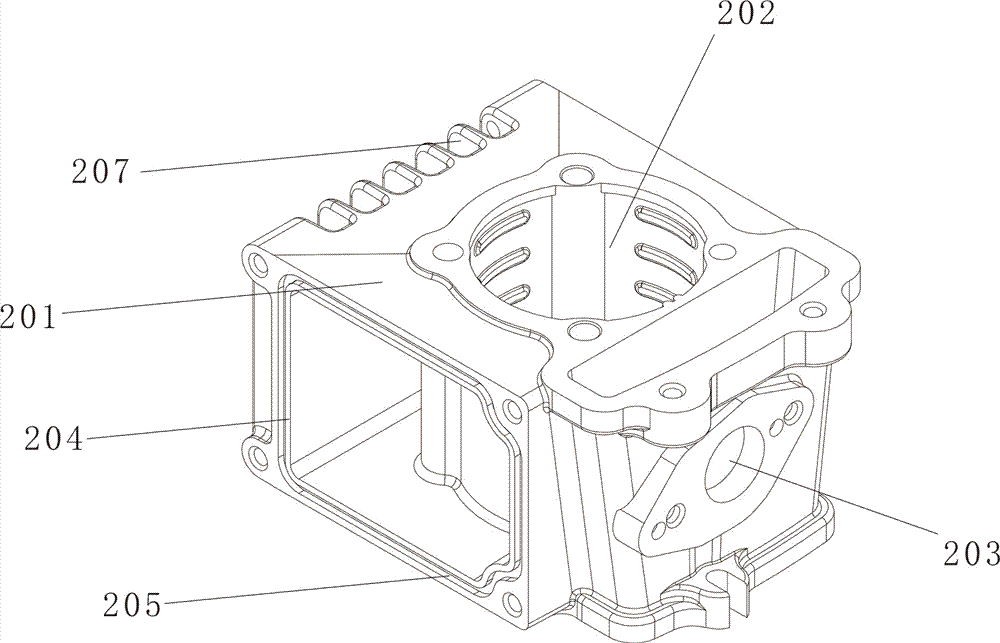

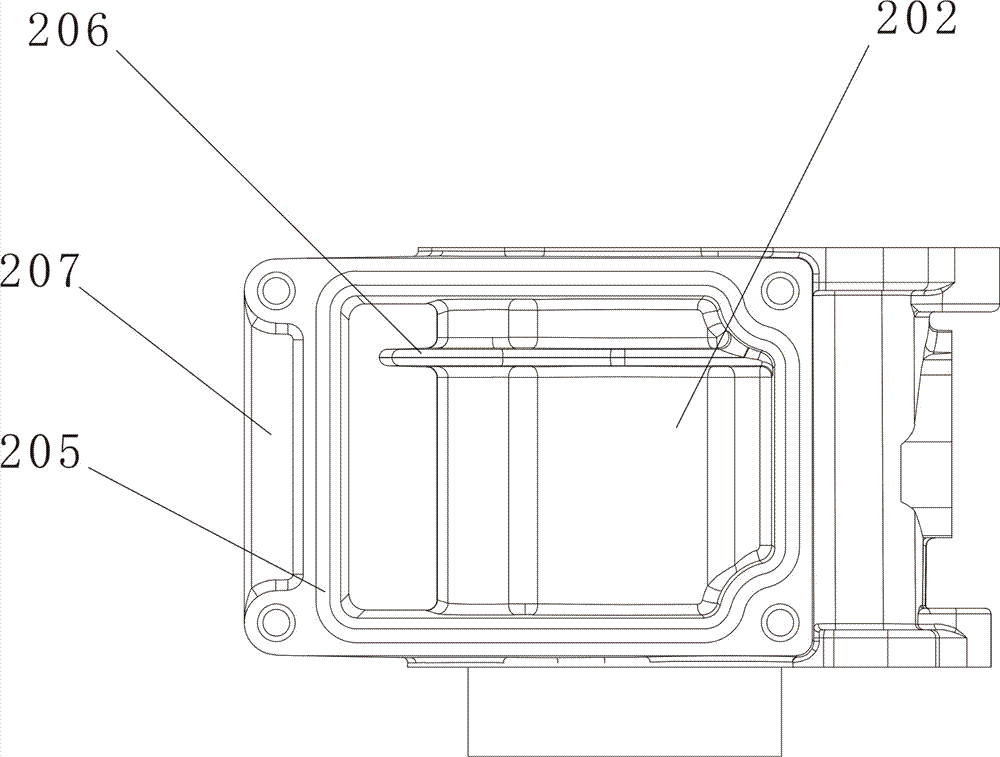

[0015] Depend on figure 1 and figure 2 As shown, a cooling water chamber structure of a range extender engine includes a cold water chamber 201 and a cylinder liner 202 arranged in the cold water chamber 201; a water inlet 203 and a water outlet window 204 are arranged on the cold water chamber 201, and the water outlet window 204 A sealing groove 205 is also provided along the edge of the window on the outer side of the cylinder liner 202 for installing sealing components; an inner cooling fin 206 is arranged on the side wall of the cylinder liner 202, and the inner cooling fin 206 is installed on the upper position of the side wall of the cylinder liner 202, Its sheet structure is parallel to the bottom surface of the cold water chamber 201, and the inner heat sink 206 is installed on all parts of the cold water chamber 201 along the circumference of the side wall of the cylinder liner 202, and the installation position of the inner heat sink 206 is close to the cylinder bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com