Optical fiber sensing system and multi-parameter monitoring method for reciprocating compressor

A technology of optical fiber sensing system and compressor, which is applied in the direction of liquid variable capacity machinery, pump testing, mechanical equipment, etc., can solve the problems of signal incapability of long-distance transmission, poor temperature stability, etc., and achieve strong anti-electromagnetic interference ability, The effect of high precision and intrinsic safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

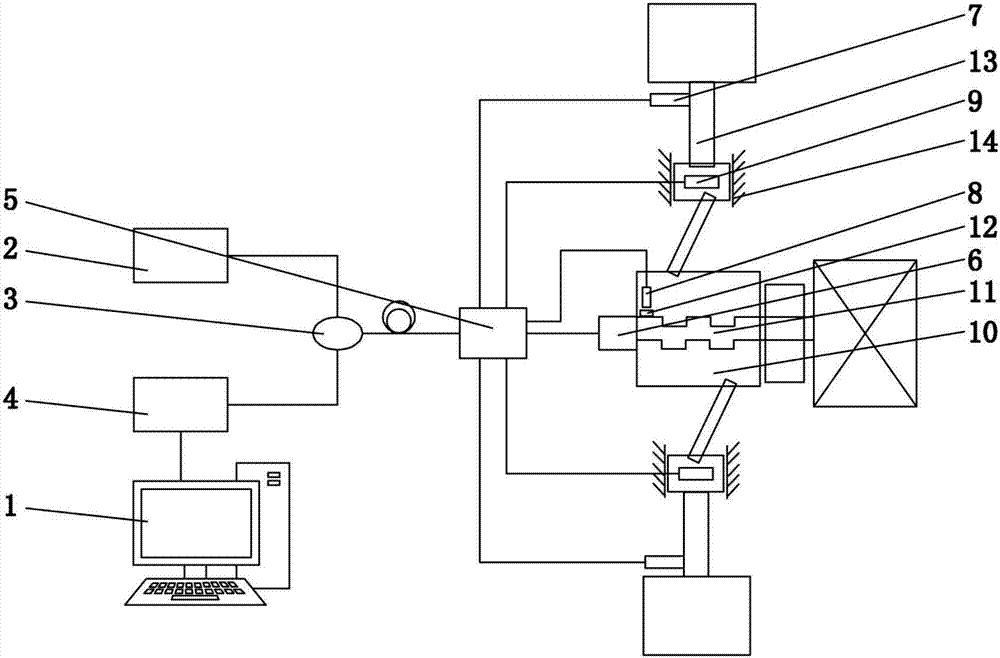

[0021] Such as figure 1 As shown, an optical fiber sensing system for a reciprocating compressor according to the present invention includes a computer 1, a light source module 2, an optical ring device 3, a signal demodulation unit 4, a splitter 5 and a sensing module, The splitter 5 is respectively connected with the light source module 2, the sensing module and the signal demodulation unit 4 through an optical fiber, and the signal demodulation unit 4 is connected with the computer 1 through a data line; the sensing module includes an optical fiber F-P acceleration sensor 6, FBG displacement sensor 7, optical bond phase sensor 8 and FBG temperature sensor 9.

[0022] Described optical fiber F-P acceleration sensor 6 is installed on the crankcase 10 of compressor, is used for detecting the vibration of reciprocating compressor cran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com