Check valve and scroll compressor provided with same

A technology of scroll compressors and check valves, applied in the field of compressors, can solve the problems of many enthalpy-increasing check structure parts, complex machining and assembly processes, etc., and achieve simple check principle, small clearance volume, Good anti-return effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

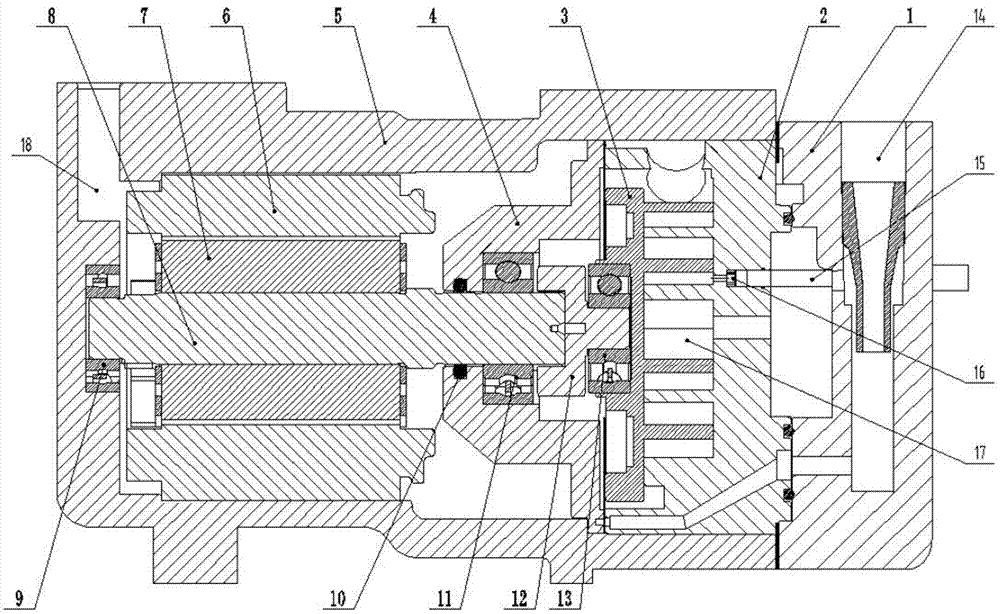

[0030] figure 1 Shown is a basic structure of a horizontal vehicle-mounted scroll compressor with a check valve of the present invention, which includes: an upper cover 1, a fixed scroll 2, a movable scroll 3, a support seat 4, and a housing 5 ; Drive motor stator 6, drive motor rotor 7, crankshaft 8, auxiliary bearing 9, back pressure chamber shaft seal 10, main bearing 11, flexible eccentric bushing 12, moving disk drive bearing 13, exhaust channel 14, enthalpy increasing connecting pipe 15. Check valve 16, compression cavity 17, suction channel 18. The check valve provided by the present invention can also be well applied to a traditional vertical scroll compressor. Here, only the above-mentioned solution is used to describe the application carrier of the present invention.

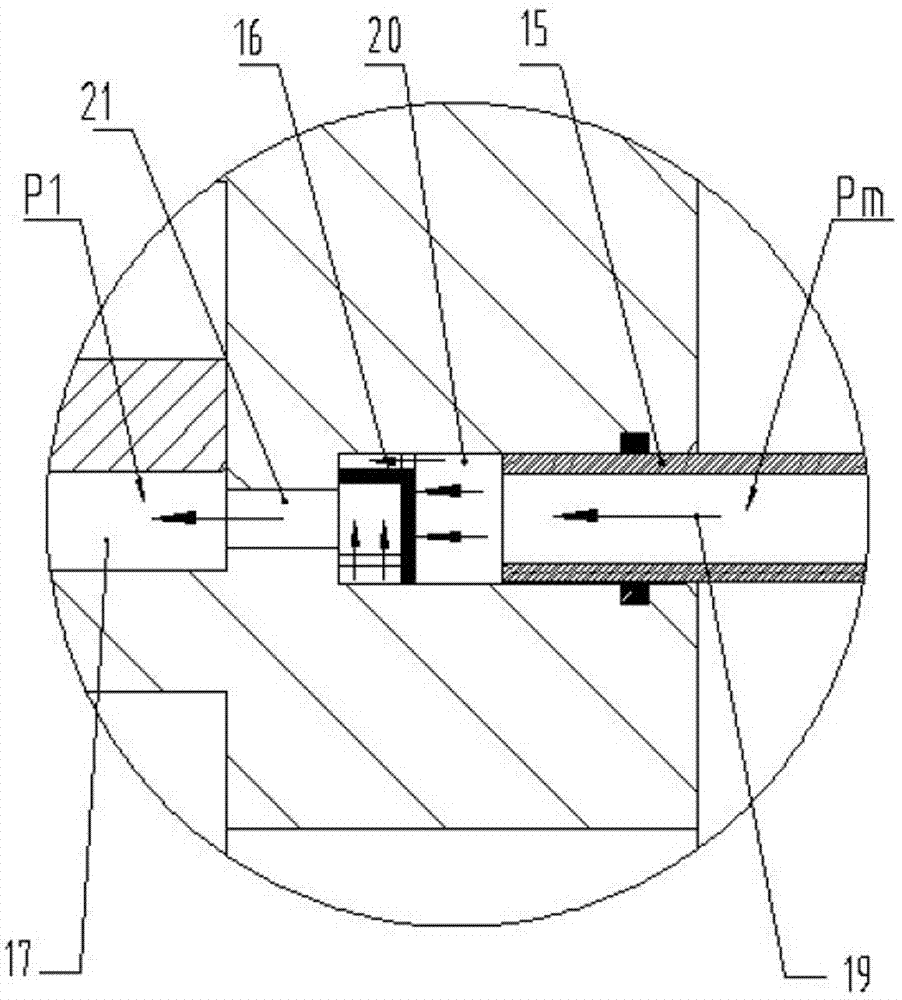

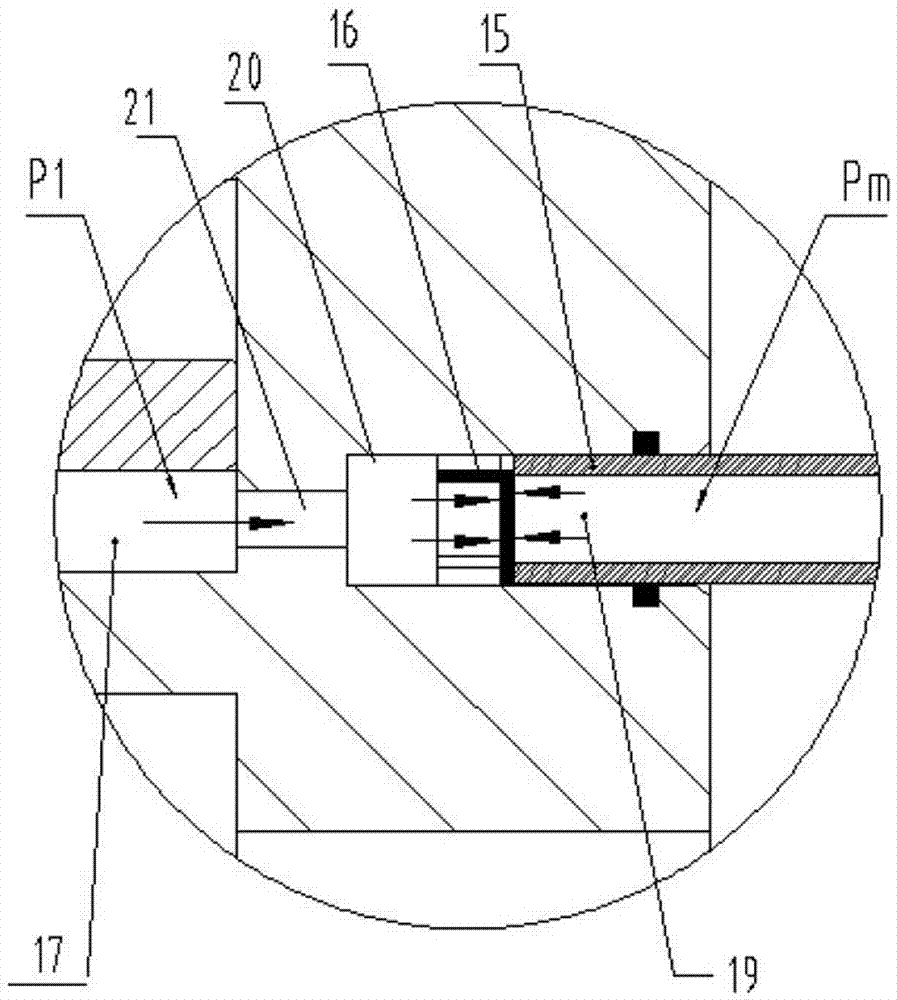

[0031] Such as figure 1 , figure 2 , image 3 As shown, the drive motor sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com